Water absorption core and preparation method and application thereof

A technology of water-absorbing core and water-absorbing layer, which is applied in the field of hygiene products, can solve problems such as reverse osmosis, reduce water absorption, use time, and affect comfort, and achieve fast water absorption speed, good water locking effect, and good water absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

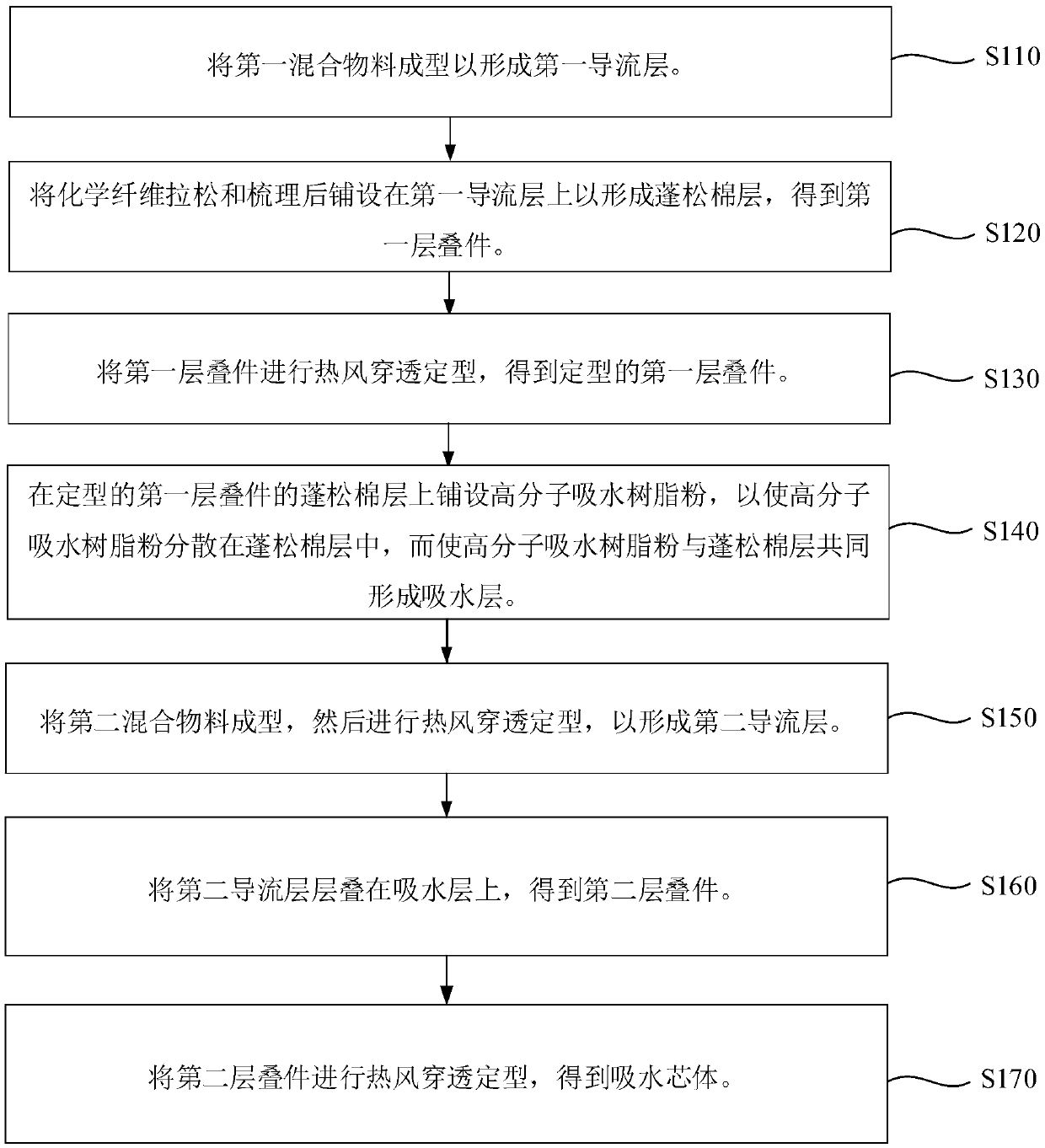

[0037] Such as figure 1 Shown, the preparation method of the water-absorbent core body of an embodiment, comprises the following steps:

[0038] Step S110: Molding the first mixed material to form a first flow-guiding layer.

[0039] Specifically, the first flow guide layer is in the shape of a sheet. Wherein, according to mass percentage, the first mixed material includes 50%-99% fluff pulp mixed with 1%-50% hot-melt fiber.

[0040] Wherein, fluff pulp is straw pulp or wood pulp, preferably wood pulp. Because the fibers in straw pulp are short, the diversion effect is poor, while compared with straw pulp, the fibers in wood pulp are longer and have better diversion effect.

[0041] Among them, the hot-melt fiber includes polypropylene fiber and polyethylene fiber. Specifically, in the hot-melt fibers, the mass ratio of polypropylene fibers to polyethylene fibers is (2-5):(5-8).

[0042] Among them, the length of the hot-melt fiber is 3 mm to 8 mm, and the specification i...

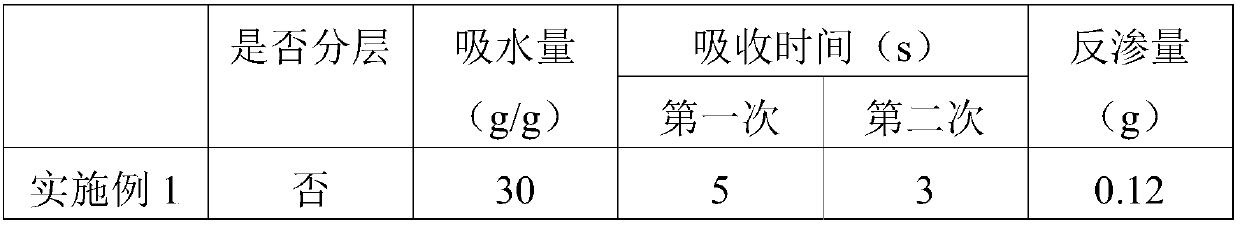

Embodiment 1

[0085] The preparation process of the water-absorbent core of the present embodiment is as follows:

[0086] (1) Pulverize the fluff pulp and pass it through a mesh sieve with a diameter of 5 mm, then mix the fluff pulp with the hot-melt fiber according to the mass percentage of 80%:20%, to obtain the first mixed material. Air pressure molding is performed on the first mixed material to obtain the first flow-guiding layer. Among them, the fluff pulp is wood pulp; the hot-melt fiber is polypropylene fiber and polyethylene fiber, the mass percentage of polypropylene fiber and polyethylene fiber is 4:6, the length of hot-melt fiber is 3 mm to 8 mm, and the specification is 3D .

[0087] (2) The chemical fiber is vibrated in the bale opener, and sent to the opener by air for stretching. The chemical fiber after stretching is sent into the final cotton box for storage by air, and then sent into the automatic cotton box by air. Quantitatively carried out in the carding machine and t...

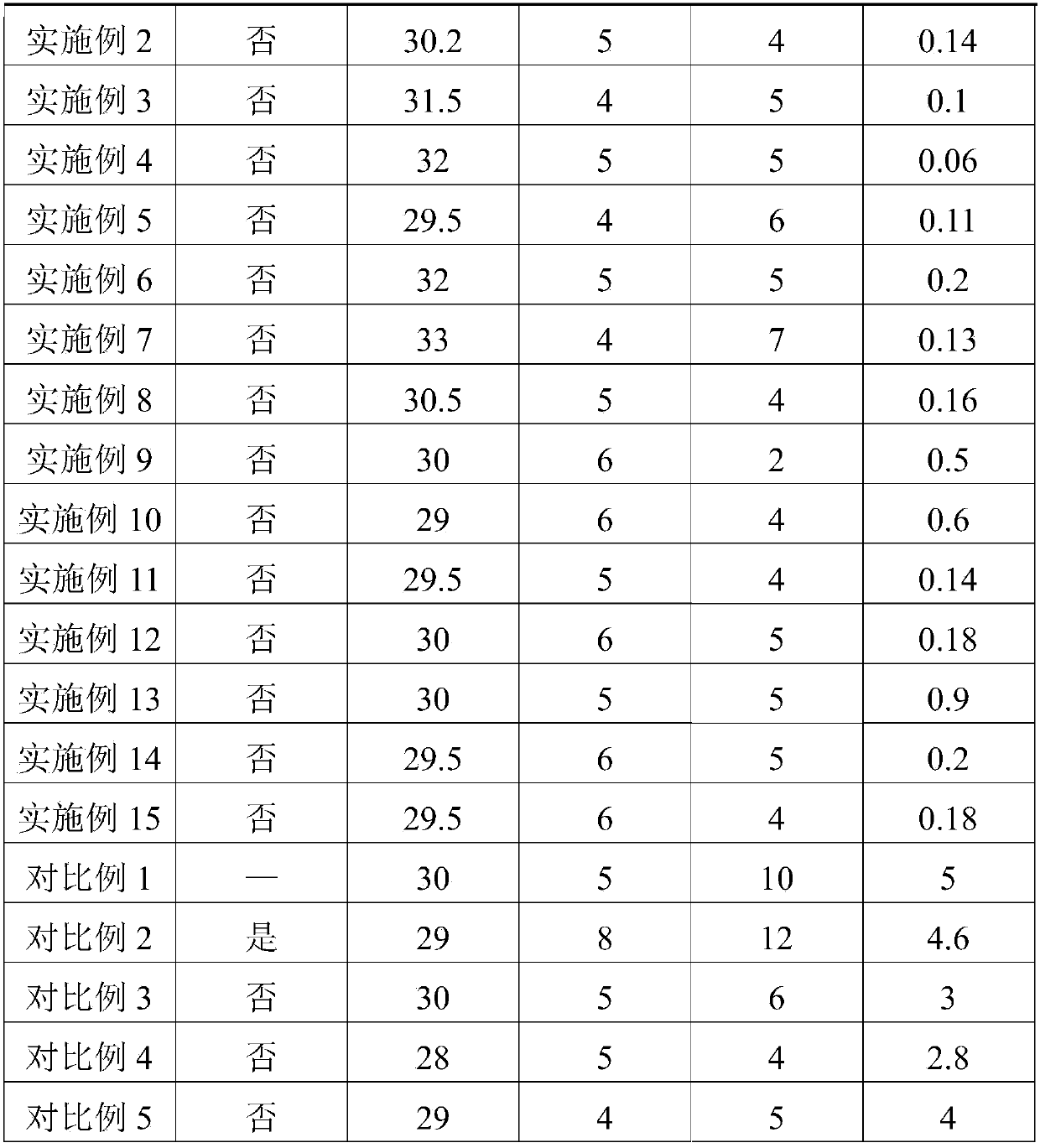

Embodiment 2

[0095] The preparation process of the water-absorbent core of the present embodiment is as follows:

[0096] (1) Pulverize the fluff pulp and pass it through a mesh sieve with a diameter of 2.5 mm, then mix the fluff pulp with the hot-melt fiber according to the mass percentage of 64.7%:35.3%, to obtain the first mixed material. Air pressure molding is performed on the first mixed material to obtain the first flow-guiding layer. Among them, the fluff pulp is wood pulp; the hot-melt fiber is polypropylene fiber and polyethylene fiber, the mass percentage of polypropylene fiber and polyethylene fiber is 2:5, the length of hot-melt fiber is 3 mm to 8 mm, and the specification is 2D .

[0097] (2) The chemical fiber is vibrated in the bale opener, and sent to the opener by air for stretching. The chemical fiber after stretching is sent into the final cotton box for storage by air, and then sent into the automatic cotton box by air. Quantitatively carried out in the carding machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com