Ordinary pressure preparation method for aluminium oxide composite aerogel rapped by silicon dioxide

A technology of composite airgel and silica, which is applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of reducing the heat insulation effect of materials, harsh conditions, and high density, and achieve equipment and daily Low maintenance investment, mild reaction conditions, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

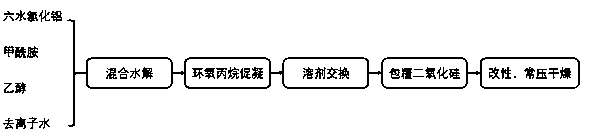

[0030] Drying at normal pressure to prepare silica-coated alumina composite airgel comprises the following steps:

[0031] 1) Mix aluminum chloride hexahydrate, absolute ethanol, deionized water and formamide in a beaker at a mass ratio of 2:2.5:2.3:0.25 to form a mixed solution, stir and hydrolyze for 3 hours, add to the hydrolyzed mixed solution Add propylene oxide at a volume ratio of 2:1 (that is, the volume ratio of the mixture to propylene oxide is 2:1), continue to stir for 1 minute, then stop, and wait for gel at room temperature;

[0032] 2) After the solution in the beaker is solidified into a gel, place the beaker in a 40°C water bath for constant temperature aging for 20 hours, then add absolute ethanol to the aged gel in the beaker at a mass ratio of 1:1.5 (i.e. The mass ratio of glue to absolute ethanol is 1:1.5), cover the plastic wrap through the upper opening of the beaker, seal and soak for 24 hours for solvent exchange;

[0033] 3) Step 2) After the solvent...

Embodiment 2

[0044] Drying at normal pressure to prepare silica-coated alumina composite airgel comprises the following steps:

[0045] 1) Mix aluminum chloride hexahydrate, absolute ethanol, deionized water and formamide in a beaker at a mass ratio of 2:3.5:3:0.35 to form a mixed solution, stir and hydrolyze for 5 hours, add to the hydrolyzed mixed solution Add propylene oxide at a volume ratio of 2:1.3, continue to stir for 3 minutes and then stop, and stand at room temperature to wait for the gel;

[0046] 2) After the solution in the beaker is solidified into a gel, place the beaker in a 40°C water bath for constant temperature aging for 20 hours, then add absolute ethanol to the aged gel in the beaker at a mass ratio of 1:1.5, and pass through the beaker The upper opening is covered with plastic wrap, sealed and soaked for 36 hours for solvent exchange;

[0047] 3) Step 2) After the solvent exchange, remove the ethanol in the beaker, and add a mixture of tetraethyl orthosilicate and ...

Embodiment 3

[0051] Drying at normal pressure to prepare silica-coated alumina composite airgel comprises the following steps:

[0052] 1) Mix aluminum chloride hexahydrate, absolute ethanol, deionized water and formamide in a beaker at a mass ratio of 2:3:2.8:0.3 to form a mixed solution, stir and hydrolyze for 4 hours, add to the hydrolyzed mixed solution Add propylene oxide at a volume ratio of 2:1.1, continue to stir for 2 minutes and then stop, and stand at room temperature to wait for the gel;

[0053] 2) After the solution in the beaker is solidified into a gel, place the beaker in a 40°C water bath for constant temperature aging for 18 hours, then add absolute ethanol to the aged gel in the beaker at a mass ratio of 1:1.2, and pass through the beaker Cover the upper opening with plastic wrap, seal and soak for 28 hours for solvent exchange;

[0054] 3) Step 2) After the solvent exchange, remove the ethanol in the beaker, and add a mixture of tetraethyl orthosilicate and absolute e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com