Preparation device and preparation method of metal powder

A preparation device and metal powder technology, which is applied in the field of metal powder preparation devices, can solve the problem of low powder extraction rate, achieve the effect of fast powder speed, uniform spreading, and spherical shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

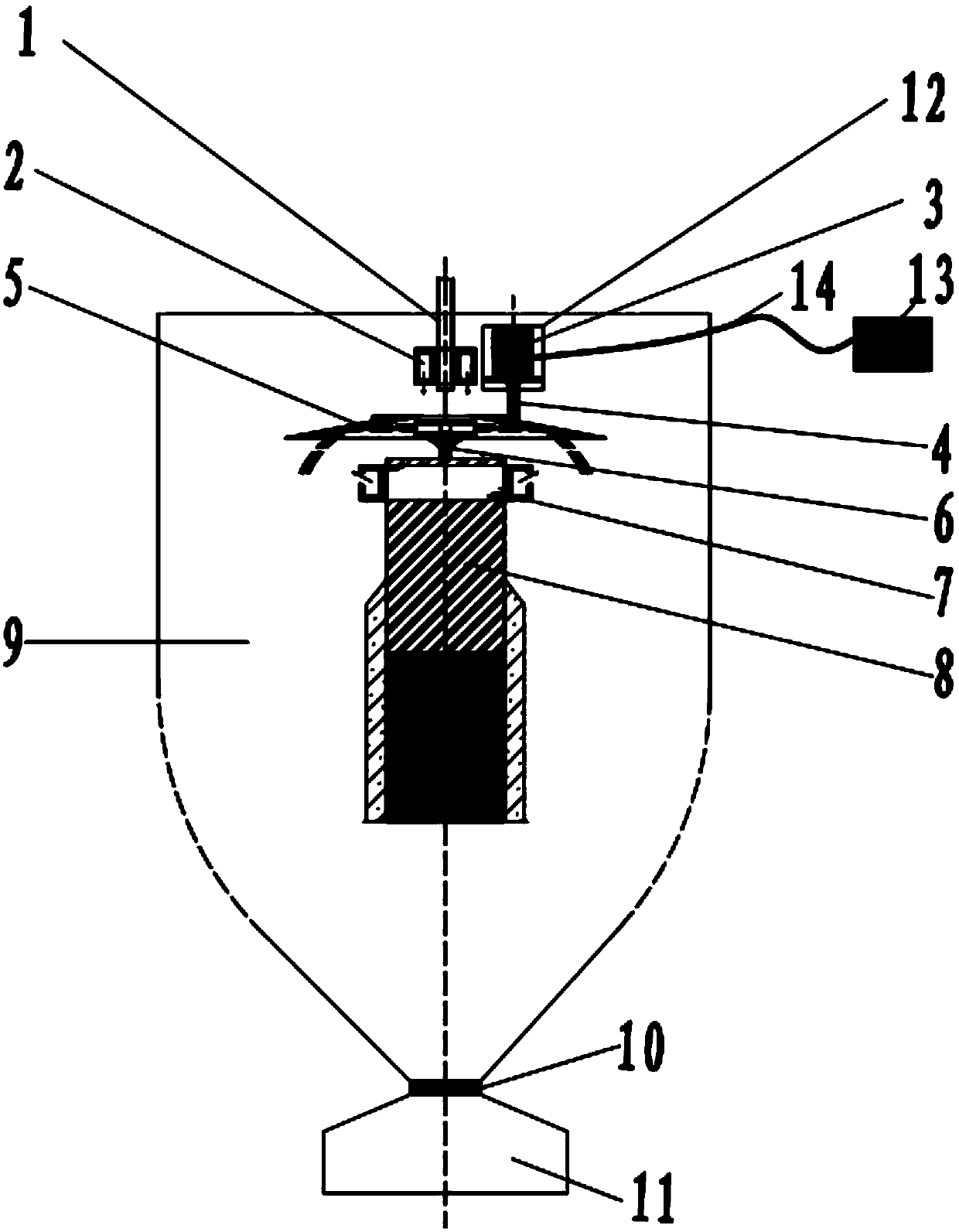

[0042] figure 1 In the preparation device shown, the volumetric flow rate of the catheter 1 is 2-20 L / min, the rotational speed of the rotary liquid distributor 6 is 100-1000 rpm / min, and the working frequency of the ultrasonic atomizer 5 is 20-40 KHz.

[0043] Utilize this novel composite ultrasonic atomization device to realize the preparation method of spherical powder needs to be realized by the following steps: Install each device in the atomization tank 9 as required, vacuumize the atomization tank 9 to 10Pa, and fill nitrogen protection until the atomization tank 9 Oxygen content is below 400ppm. Turn on the ultrasonic atomization power supply, and turn on the rotating spindle of the rotary liquid distributor. The molten metal is transported to the rotary liquid distributor through the catheter, and the rotating rotary liquid distributor controls the molten metal to be evenly distributed on the inner surface of the ultrasonic atomizer, and the ultrasonic vibration on t...

Embodiment 1

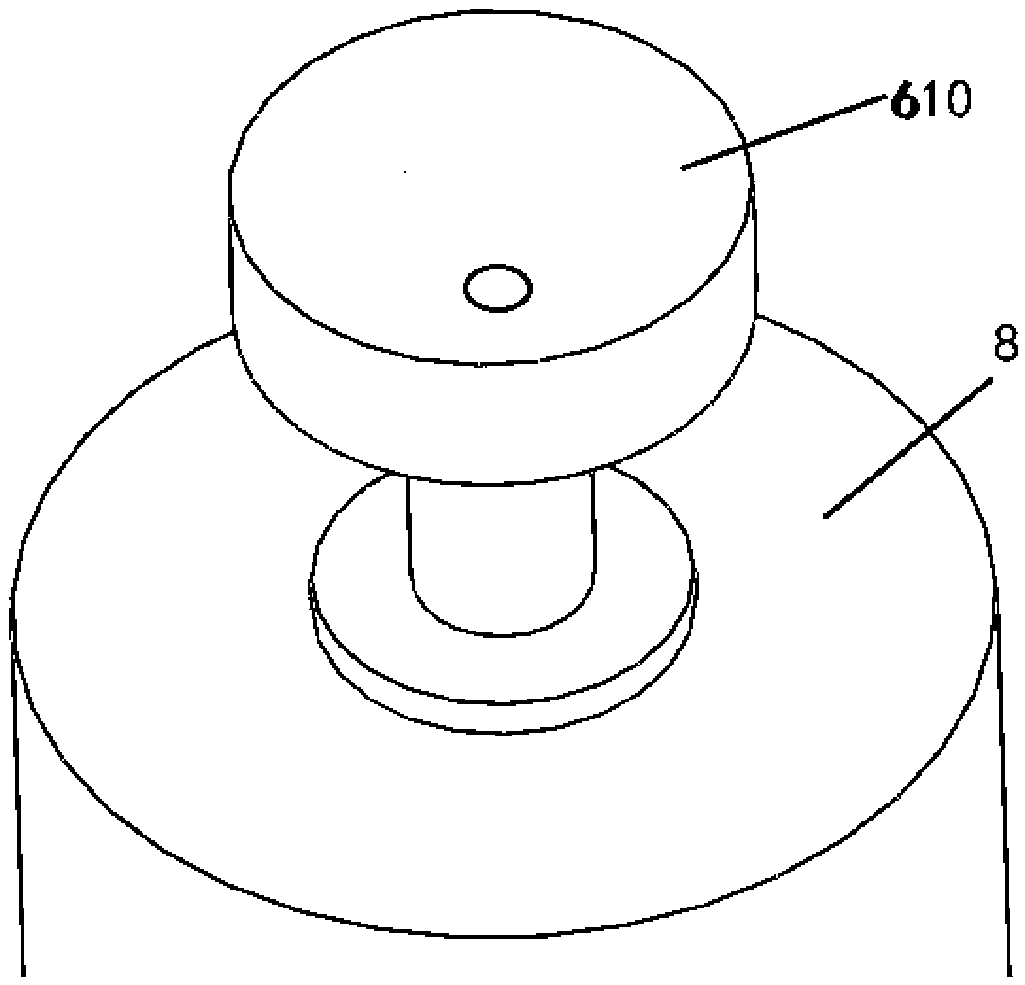

[0046] In this embodiment, the structure of the rotating liquid distributor (A) is selected to assemble the preparation device. The rotating liquid distributor (A) has a diameter of 50mm and a taper of 30°. In this embodiment, the working speed of the high-speed electric spindle is 600 rpm / min. The angle of the upper gas injection ring is 75°, and the gas flow rate is 150mL / min, so as to ensure that the gas flow field in the atomization area is downward and reduce the probability of particle collision in the atomization area. The angle of the lower jet ring is 45°, and the gas flow rate is 1200mL / min, so as to ensure that the powder particles formed by flying out of the ultrasonic atomizer fly away from the atomization area quickly. In this embodiment, the catheter, the rotary liquid distributor, the ultrasonic nebulizer, and the power electric spindle are in concentric cooperation, so as to facilitate the working stability of the device and the smooth and stable transfer of ...

Embodiment 2

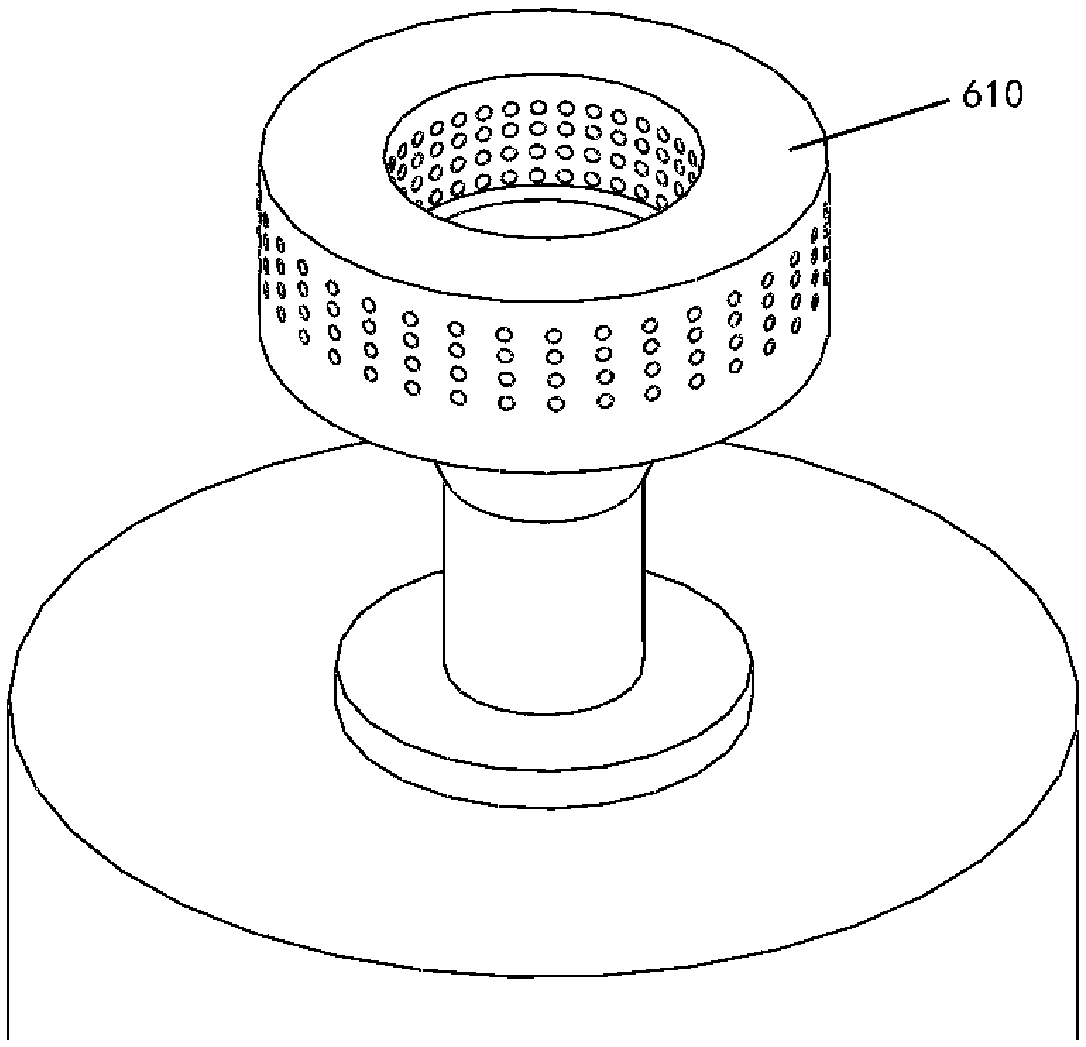

[0049] In this embodiment, the structure of the rotating liquid distributor (B) is selected to assemble the preparation device. The rotary liquid distributor (B) has 12 single-layer ring holes, and 4 layers are evenly distributed. The diameter of a single ring hole is 0.5mm, the diameter of the rotary liquid distributor is 50mm, and the diameter of the inner ring is 40mm, so as to increase the liquid stock of the rotary liquid distributor and ensure Melt can fly out from all layers. In this embodiment, the high-speed electric spindle operates at a rotational speed of 400 rpm / min, so that the metal liquid can quickly fly out of the rotary liquid distributor, and quickly lay a film on the ultrasonic atomizer. The angle of the upper gas injection ring is 75°, and the gas flow rate is 150mL / min, so as to ensure that the gas flow field in the atomization area is downward and reduce the probability of particle collision in the atomization area. The angle of the lower jet ring is 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com