Manganese-doped magnetic carbon and preparation and application of magnetic carbon in dark fermentation hydrogen production

A technology of manganese doping and magnetic carbon, applied in fermentation, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as high energy consumption, limited application, pollution, etc., and achieve the effect of increasing hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the manganese-doped magnetic carbon, the specific steps are as follows:

[0043] A. 1 ~ 3g MnCl 2 4H 2 O and 2.6~7.8g FeCl 3 ·6H 2 O particles were dissolved in 100-200ml of deionized water, 12-36.4g of activated carbon was added, stirred for 1-2 hours, and fully mixed to obtain a mixed solution of iron, manganese and carbon. At this time, MnCl 2 Solution concentration is 5~30g / L; FeCl 3 The concentration is 13-78g / L; the concentration of activated carbon is 60-364g / L; weigh 1.72-2.24g NaOH particles and dissolve them in deionized water to obtain a lye with a pH of 10-12 and a NaOH concentration of 34.4-129g / L;

[0044] B. The above mixed solution is heated and refluxed in an oil bath in a reactor, and the reactor is connected to a condensing reflux pipe. After the mixture boils, quickly pour 50ml of 50g / L NaOH solution into the mixture, and stir to mix;

[0045] C. The above mixed solution is boiled and refluxed at 100-130°C for 2-4 hou...

Embodiment 1

[0063] Manganese doped magnetic carbon:

[0064] a. 1.5g MnCl 2 4H 2 O and 4.1 g FeCl 3 ·6H 2 O particles were dissolved in 150ml of deionized water, 24g of activated carbon was added, stirred for 1.5h, and fully mixed to obtain a mixture of iron, manganese and carbon. MnCl 2 The solution concentration is 10g / L; FeCl 3 The concentration is 27g / L; the concentration of activated carbon is 160g / L;

[0065] b. The above mixed solution is heated and refluxed in an oil bath in a reactor, and the reactor is connected to a condensing reflux pipe; after the mixed solution boils, quickly add 50ml NaOH (50g / L) solution into the mixed solution and stir to mix;

[0066] c. The above mixed solution was boiled and refluxed at 105°C for 3 hours, and poured into a beaker to cool after the reaction was complete;

[0067] d. The mixed solution obtained in the above steps was dried at 85° C. for 10 hours to obtain manganese-doped magnetic carbon.

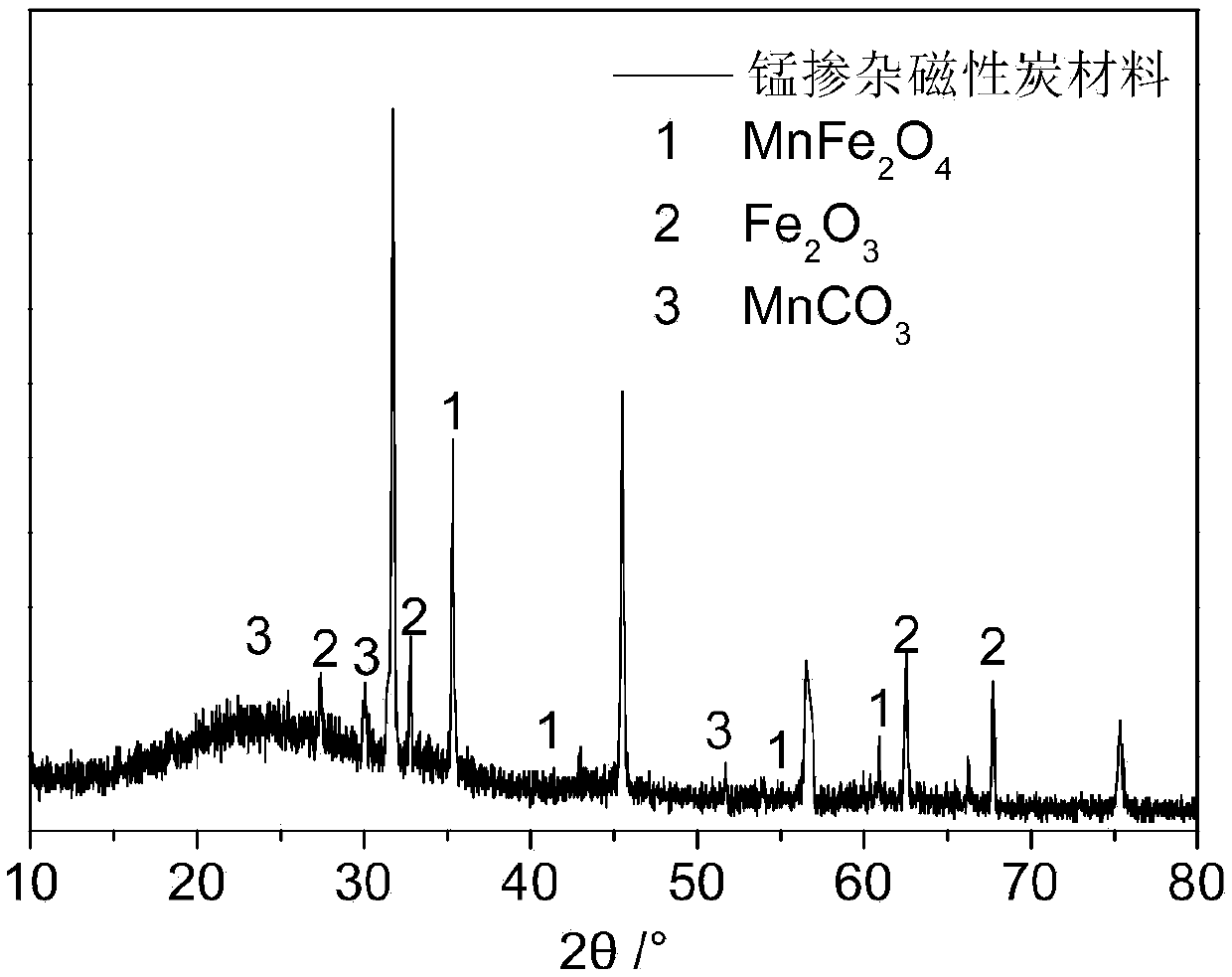

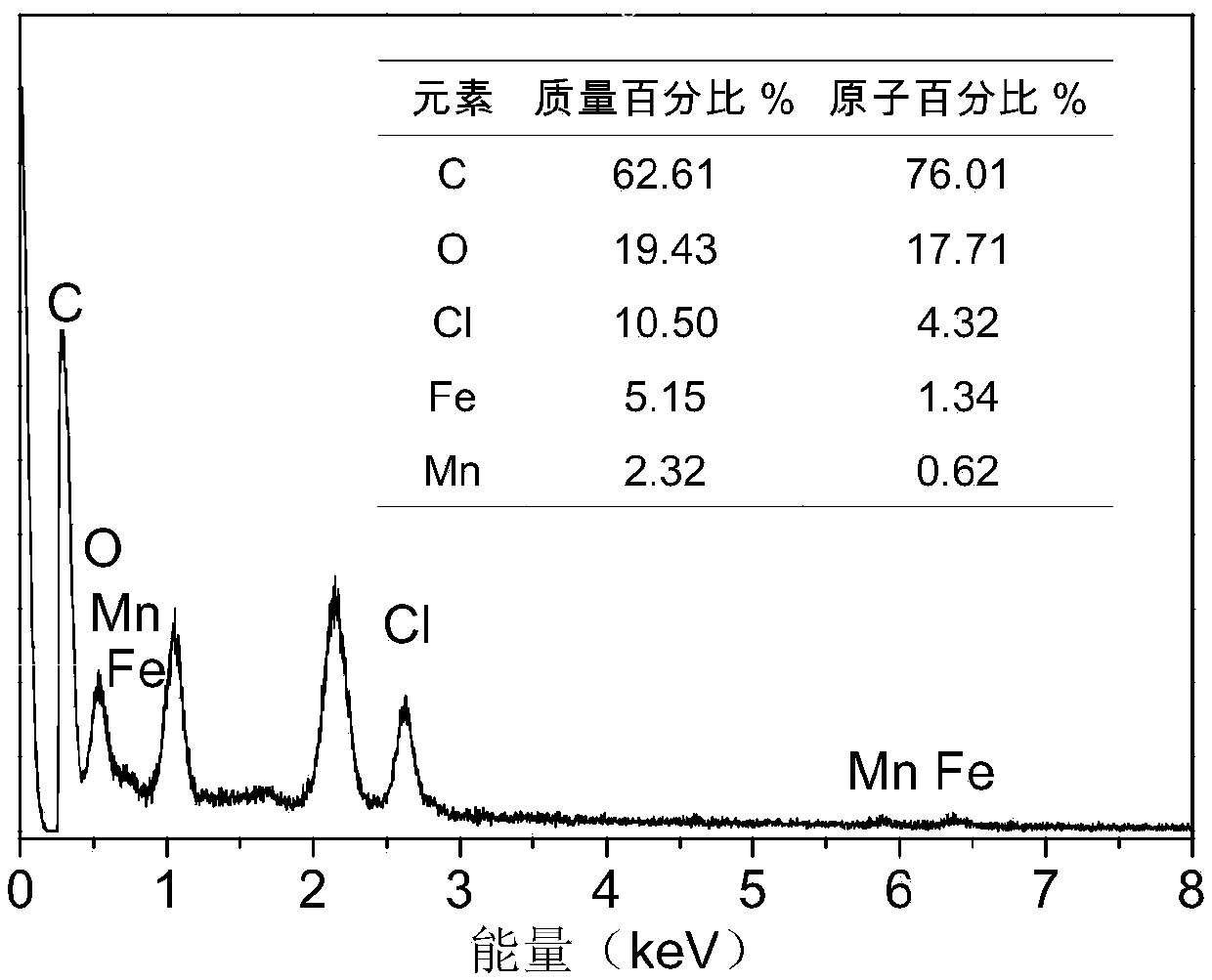

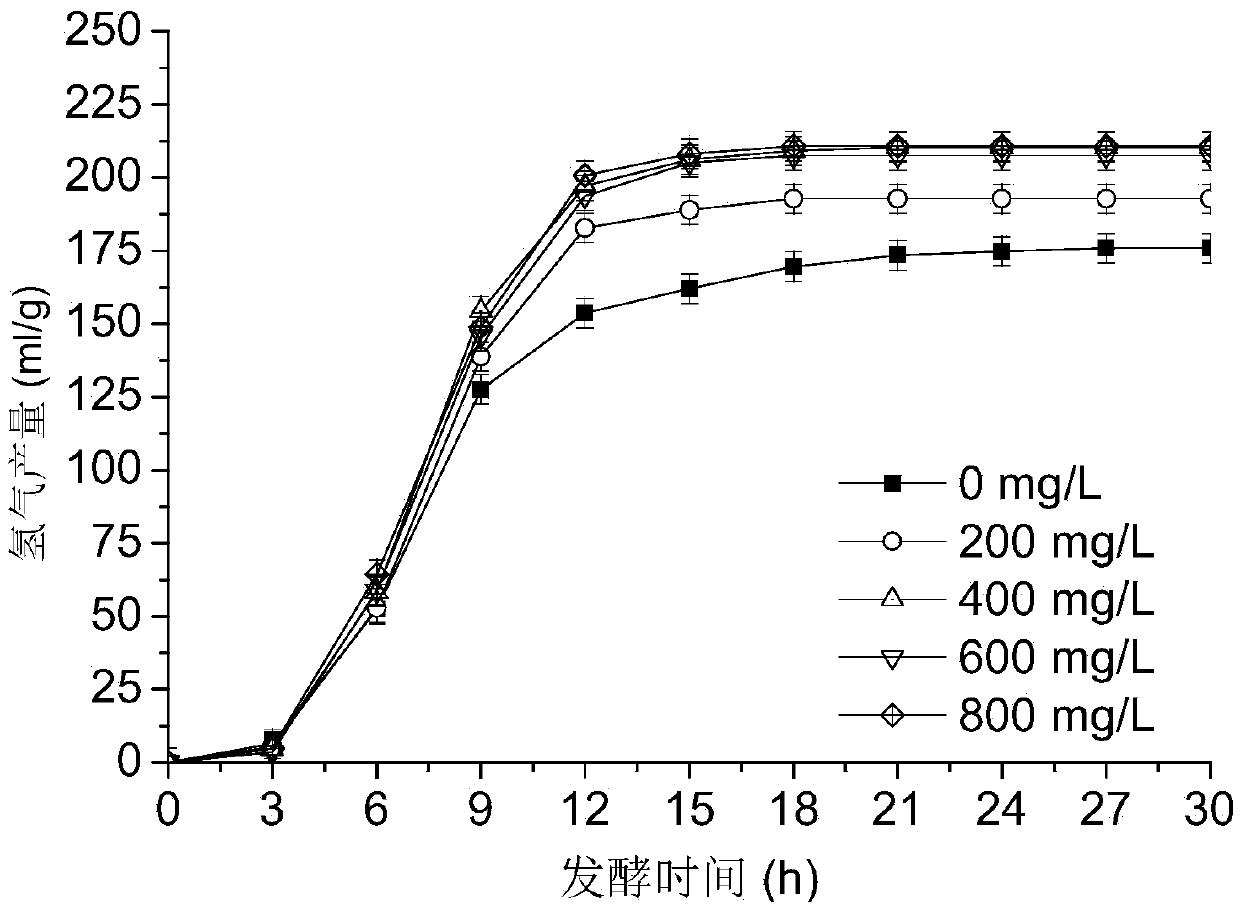

[0068] The prepared materials were analyze...

Embodiment 2

[0072] Manganese doped magnetic carbon:

[0073] a. 1g MnCl 2 4H 2 O and 2.6 g FeCl 3 ·6H 2 O particles were dissolved in 150ml of deionized water, then 12g of activated carbon was added, and stirred for 1 hour to ensure that they were fully mixed to obtain a mixture of iron, manganese and carbon. MnCl 2 The solution concentration is 6.7g / L; FeCl 3 The concentration is 14.4g / L; the concentration of activated carbon is 80g / L;

[0074] b. The above mixed solution is heated and refluxed in an oil bath in a reactor, and the reactor is connected to a condensation reflux pipe. After the solution boils, quickly add 50ml of 20g / L NaOH solution into the mixture and stir to mix;

[0075] c. The above mixed solution is boiled and refluxed at 100°C for 2 hours, and poured into a beaker to cool after the reaction is complete;

[0076] d. The mixed solution obtained in the above steps was dried at 75° C. for 15 hours to obtain manganese-doped magnetic carbon.

[0077] The as-prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com