Preparing device and method for ammonia gas

A preparation device and ammonia gas technology, applied in the direction of ammonia preparation/separation, gas generating device, feeding device, etc., can solve the problems of complicated process and high energy consumption, and achieve the goal of simplifying the reaction steps, reducing the difficulty of operation, and reducing the difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

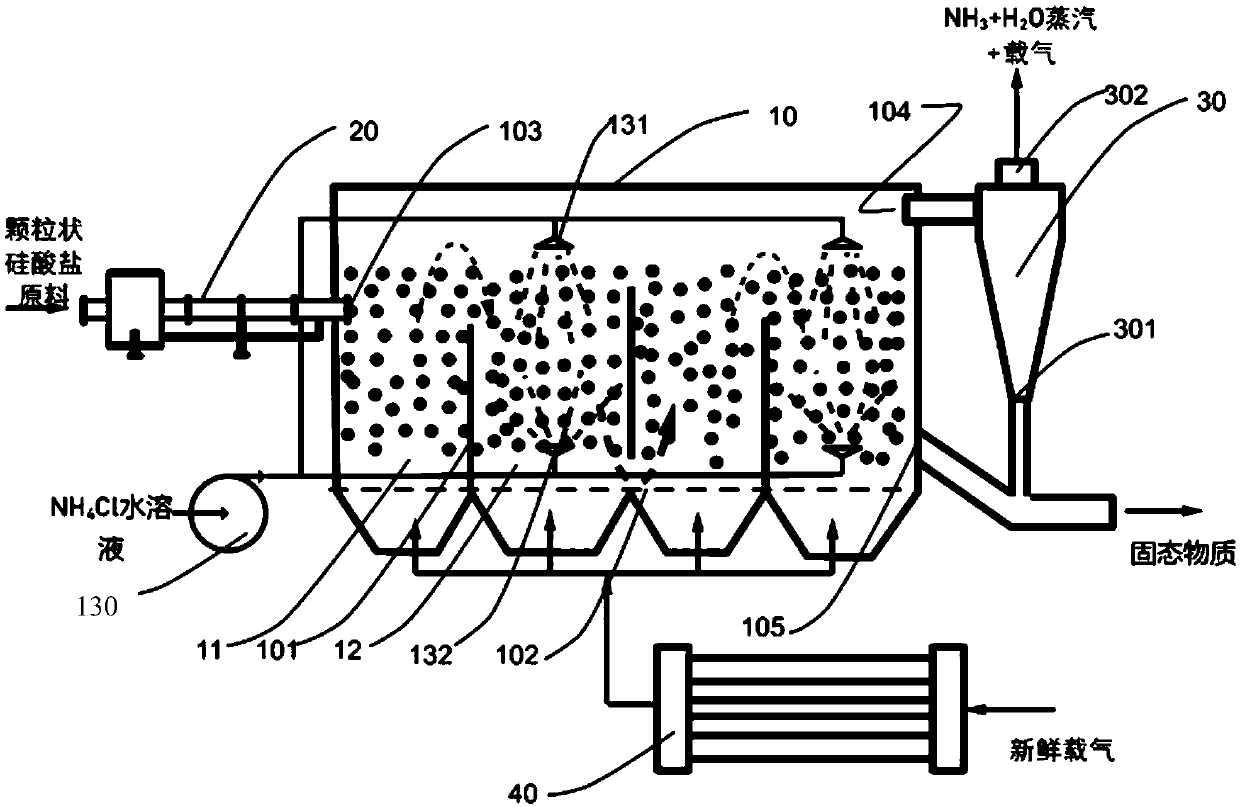

[0024] figure 1 It is a schematic diagram of the preparation device of the embodiment of the present invention. In this schematic diagram, there are 2 reaction chambers and 2 preheating chambers. Since the design and principle of the device with more reaction chambers and preheating chambers are similar, no longer in the present invention. List them all. The preparation device includes: a fluidized bed reactor 10, a solid feeder 20, a gas-solid separator 30, a gas preheater 40 and a plurality of connecting pipes.

[0025] The fluidized bed reactor 10 includes four fluidized chambers and baffles 101 arranged vertically, wherein the four fluidized chambers serve as two preheating chambers 11 and two reaction chambers 12 respectively, and the preheating chamber 11 and the reaction chamber 12 are alternately arranged, and each adjacent preheating chamber 11 and reaction chamber 12 are separated by a deflector 101 .

[0026] The fluidized bed reactor 10 also includes a gas distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com