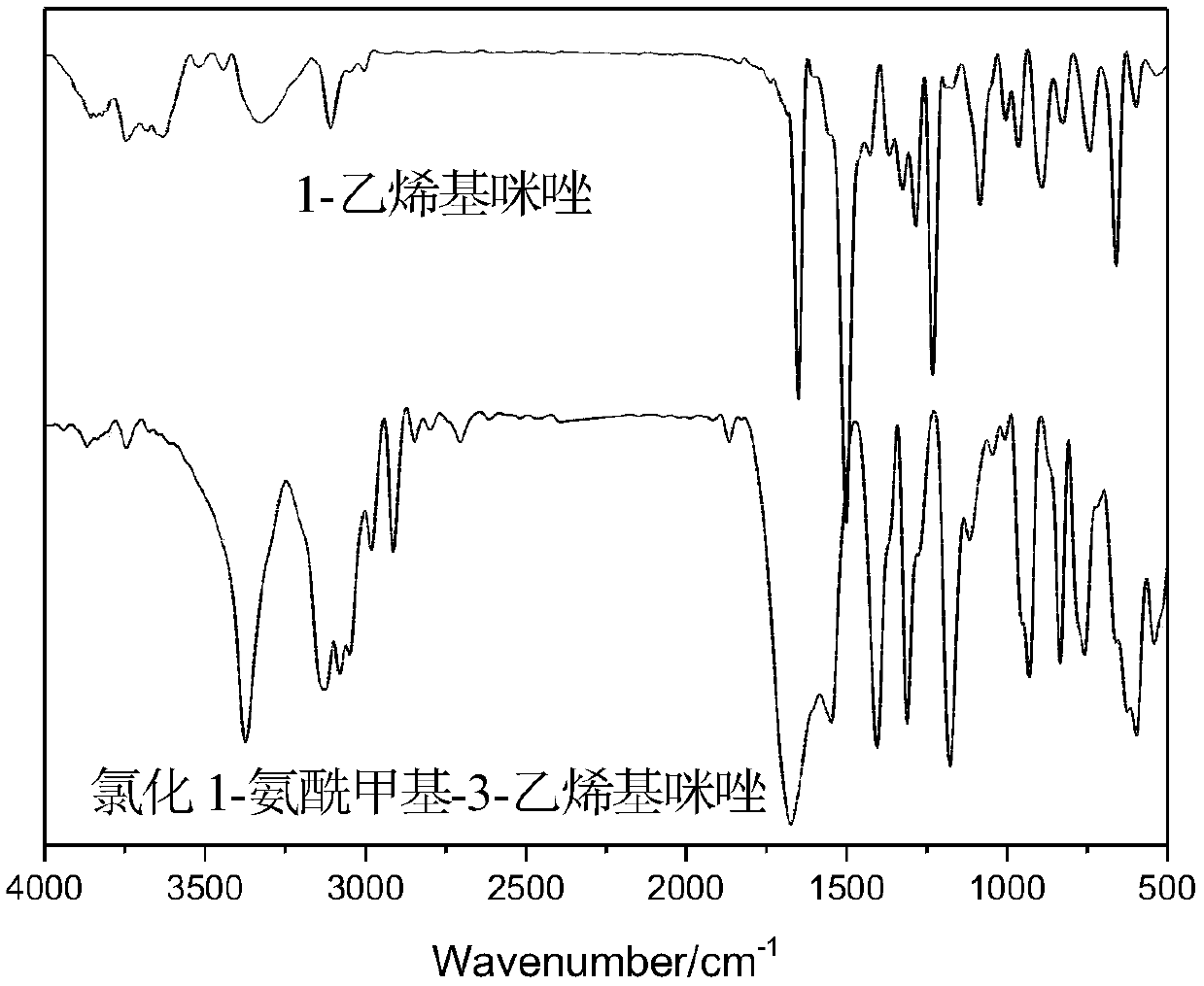

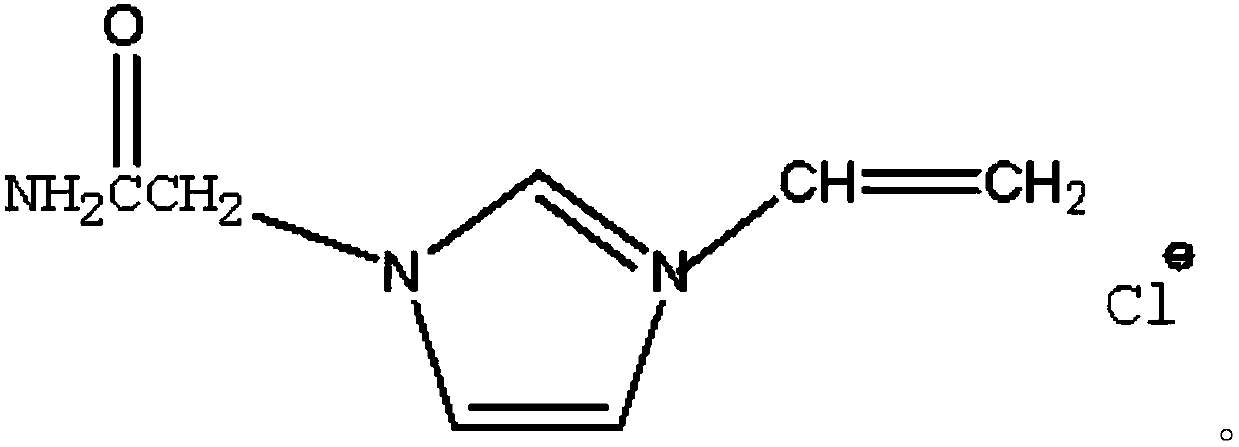

Chloridized 1-arginyl methyl-3-vinyl imidazole ionic liquid and preparation method thereof

A technology of vinylimidazole and ionic liquid, applied in the direction of organic chemistry, can solve the problems of volatile recovery, difficulty, toxicity, etc., and achieve the effect of simple reaction steps and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of chlorinated 1-aminoacylmethyl-3-vinylimidazole ionic liquid, the specific process is:

[0038] 1) Weigh 9.411g of 1-vinylimidazole, that is, 0.1mol of 1-vinylimidazole, and add it to 94.11g of ethanol solution to obtain solution 1;

[0039] 2) Add 12.143 g of triethylamine, that is, 0.12 mol of triethylamine dropwise to solution 1, and stir for 10 minutes to obtain solution 2;

[0040] 3) Dissolve 11.221g of 2-chloroacetamide, that is, 0.12mol of 2-chloroacetamide, in 56.105g of ethanol solution under heating in a water bath at 60°C. The amide solution was added dropwise to solution 2, the heating temperature was 70°C, the magnetic stirring speed was 400r / min, and the reaction time was 3h to obtain solution 3;

[0041] 4) Distill solution 3 under reduced pressure to remove the solvent in the reaction, then extract it with anhydrous ether three times, put the product in a vacuum drying oven, and dry it for 24 hours at a temperature of 80°C and a ...

Embodiment 2

[0043] A preparation method of chlorinated 1-aminoacylmethyl-3-vinylimidazole ionic liquid, the specific process is:

[0044] 1) Weigh 9.411g of 1-vinylimidazole, that is, 0.1mol of 1-vinylimidazole, and add it to 94.11g of ethanol solution to obtain solution 1;

[0045] 2) Add 11.131 g of triethylamine, i.e. 0.11 mol of triethylamine, dropwise to solution 1, and stir to obtain solution 2;

[0046] 3) Dissolve 10.286g of 2-chloroacetamide, that is, 0.11mol of 2-chloroacetamide, in 51.43g of ethanol solution under heating in a water bath at 60°C. The amide solution was added dropwise to solution 2, the microwave heating temperature was 70°C, the microwave radiation power was 300W, the magnetic stirring speed was 400r / min, and the reaction time was 3h to obtain solution 3;

[0047]4) Distill the solution 3 under reduced pressure to remove the solvent in the reaction, then extract it with toluene for 3 times, put the product in a vacuum drying oven, and dry it for 24 hours at a ...

Embodiment 3

[0049] A preparation method of chlorinated 1-aminoacylmethyl-3-vinylimidazole ionic liquid, the specific process is:

[0050] 1) Weigh 9.411g of 1-vinylimidazole, that is, 0.1mol of 1-vinylimidazole, and add it to 94.11g of ethanol solution to obtain solution 1;

[0051] 2) Add dropwise 13.155 g of triethylamine, i.e. 0.13 mol of triethylamine, to solution 1, and stir to obtain solution 2;

[0052] 3) Dissolve 12.157g of 2-chloroacetamide, that is, 0.13mol of 2-chloroacetamide, in 60.785g of ethanol solution under heating in a water bath at 60°C. The amide solution was added dropwise to solution 2, the microwave heating temperature was 70°C, the microwave radiation power was 300W, the magnetic stirring speed was 400r / min, and the reaction time was 3h to obtain solution 3;

[0053] 4) Distill the solution 3 under reduced pressure to remove the solvent in the reaction, then extract it three times with anhydrous ether, put the product in a vacuum drying oven, and dry it for 24 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com