Silicone modified Ms pavement and wall building material and manufacturing process thereof

A technology for building materials and manufacturing processes, applied in the field of organosilicon-modified Ms pavement and wall building materials and manufacturing processes, can solve problems such as aesthetic and environmental defects, harm to human health, and isocyanate toxicity, and achieve good adhesion and low cost. Low cost, effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

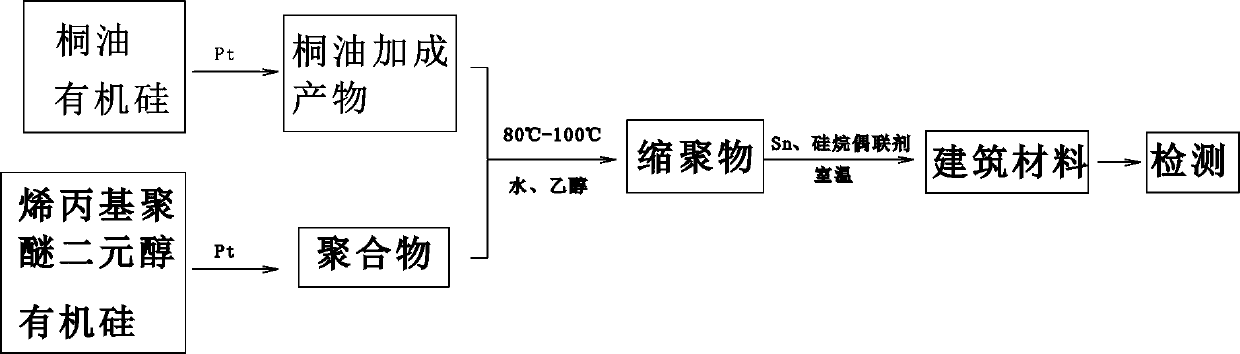

Method used

Image

Examples

Embodiment 1

[0026] A kind of manufacture technology of organosilicon modified Ms pavement wall building material, concrete steps are as follows:

[0027] 1. HCH obtained from organic silicon industry low-quality materials and photovoltaic industry low-quality materials 3 SiCl 2 Carry out esterification alcoholysis:

[0028]

[0029] HCH 3 Si(OC 2 h 5 ) 2 +2HCl+2OH - →HCH 3 Si(OC 2 h 5 ) 2 +2H 2 O+2Cl - ②

[0030] The substance obtained in reaction ② is separated to obtain HCH 3 Si(OC 2 h 5 ) 2 substance.

[0031] In this example, the organic silicon industry waste and the photovoltaic industry low waste refer to the waste generated in the industrial production process, the waste is converted into organic silicon, and the obtained organic silicon is used as raw material to turn waste into treasure, and after the reaction The produced material can be recycled, no pollution, environmental protection and energy saving.

[0032] 2. Anhydrous tung oil and methyldiethoxysi...

Embodiment 2

[0046] In this example, the composition and content of the ingredients in the building material manufacturing process are the same as in Example 1, the difference is that the reaction conditions are changed: in step 2, the anhydrous tung oil is vacuumed at 50 ° C, dehydrated for 1 hour, and methyl diethoxy is added After silane, the temperature was raised to 55°C, and finally the reaction was refluxed at 80°C for 2h.

[0047] In step 3, the allyl polyether diol is vacuumed at 65°C for 1 hour, after adding methyldiethoxysilane, the temperature is raised to 70°C, and then the catalyst is added, and finally reacted at 75°C for 1 hour.

[0048] In step 4, the reactants obtained in step 2 and step 3 were uniformly mixed at 85°C, reacted for 1 hour, added epoxy resin, cooled to 45°C, and discharged to obtain the base material.

[0049] The base material obtained in this embodiment is light yellow liquid with high viscosity, good bonding strength, average elongation and easy coloring...

Embodiment 3

[0051] In this example, the composition and content of the ingredients in the building material manufacturing process are the same as in Example 1, the difference is that the reaction conditions are changed: in step 2, the anhydrous tung oil is vacuumed at 70 ° C, dehydrated for 1 hour, and methyl diethoxy is added After silane, the temperature was raised to 65°C, and finally the reaction was refluxed at 80°C for 2h.

[0052] In step 3, the allyl polyether diol is vacuumed at 55°C for 1 hour, and after adding methyldiethoxysilane, the temperature is raised to 60°C, then the catalyst is added, and finally reacted at 70°C for 1 hour.

[0053] In step 4, the reactants obtained in step 2 and step 3 were uniformly mixed at 80°C, reacted for 1 hour, added epoxy resin, cooled to 40°C and discharged to obtain the base material.

[0054] The base material obtained in this embodiment is a light yellow transparent liquid with high viscosity, average bonding strength, high elongation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com