Patents

Literature

64results about "Drying-oils" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

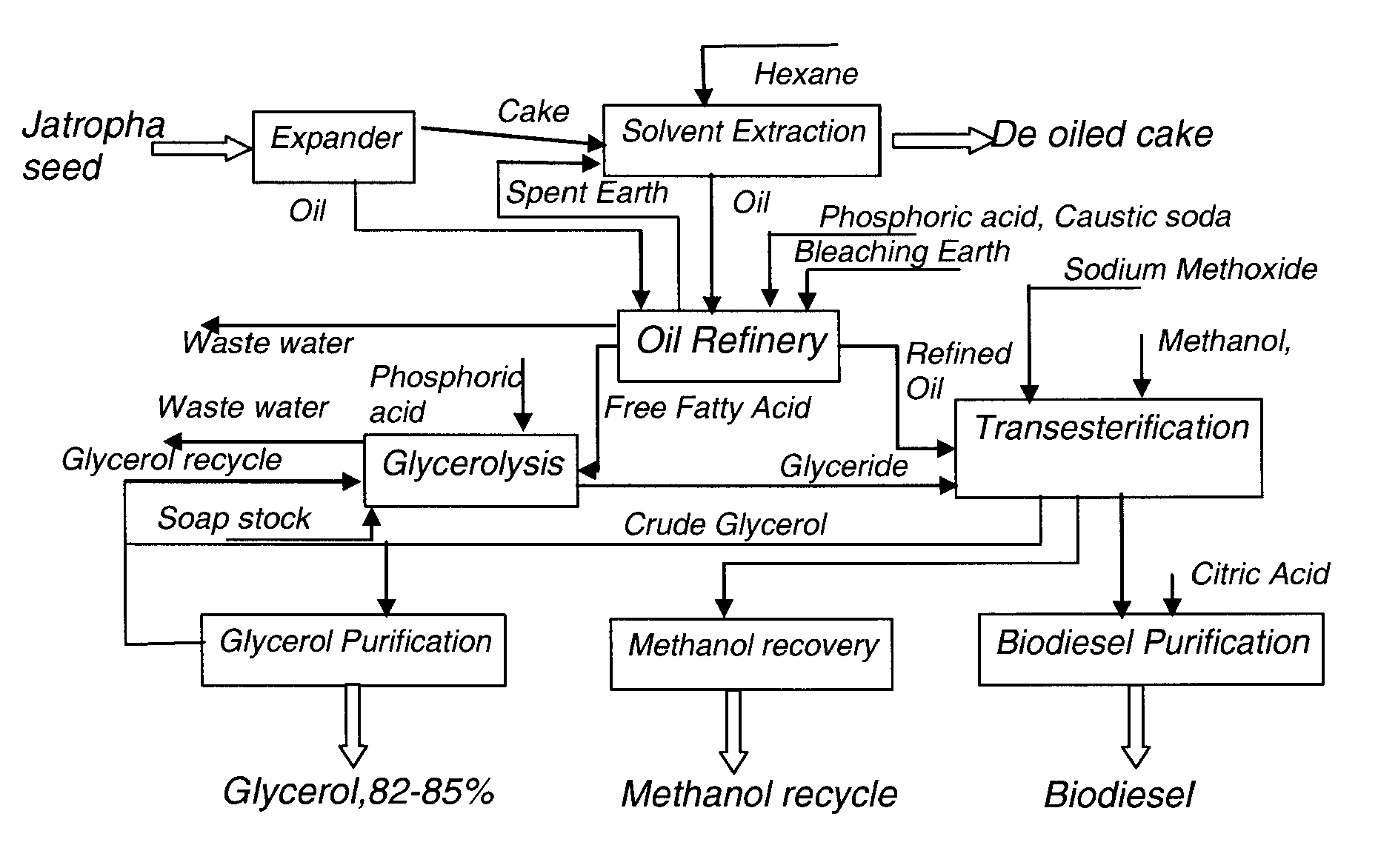

Process for the preparation of fatty acid methyl ester from triglyceride oil by transesterification

InactiveUS20060080891A1Produced cost-effectivelyReduce water contentFatty oils/acids recovery from wasteFatty acid esterificationTransesterificationUnit operation

The present invention relates to an improved process for the preparation of biodiesel from triglyceride oils through transesterification, particularly the fatty acid methyl ester of oil mechanically expelled from whole seeds of Jatropha curcas, a plant with potential for cultivation on wastelands in India and other countries, all unit operations being carried out at ambient temperature.

Owner:COUNCIL OF SCI & IND RES

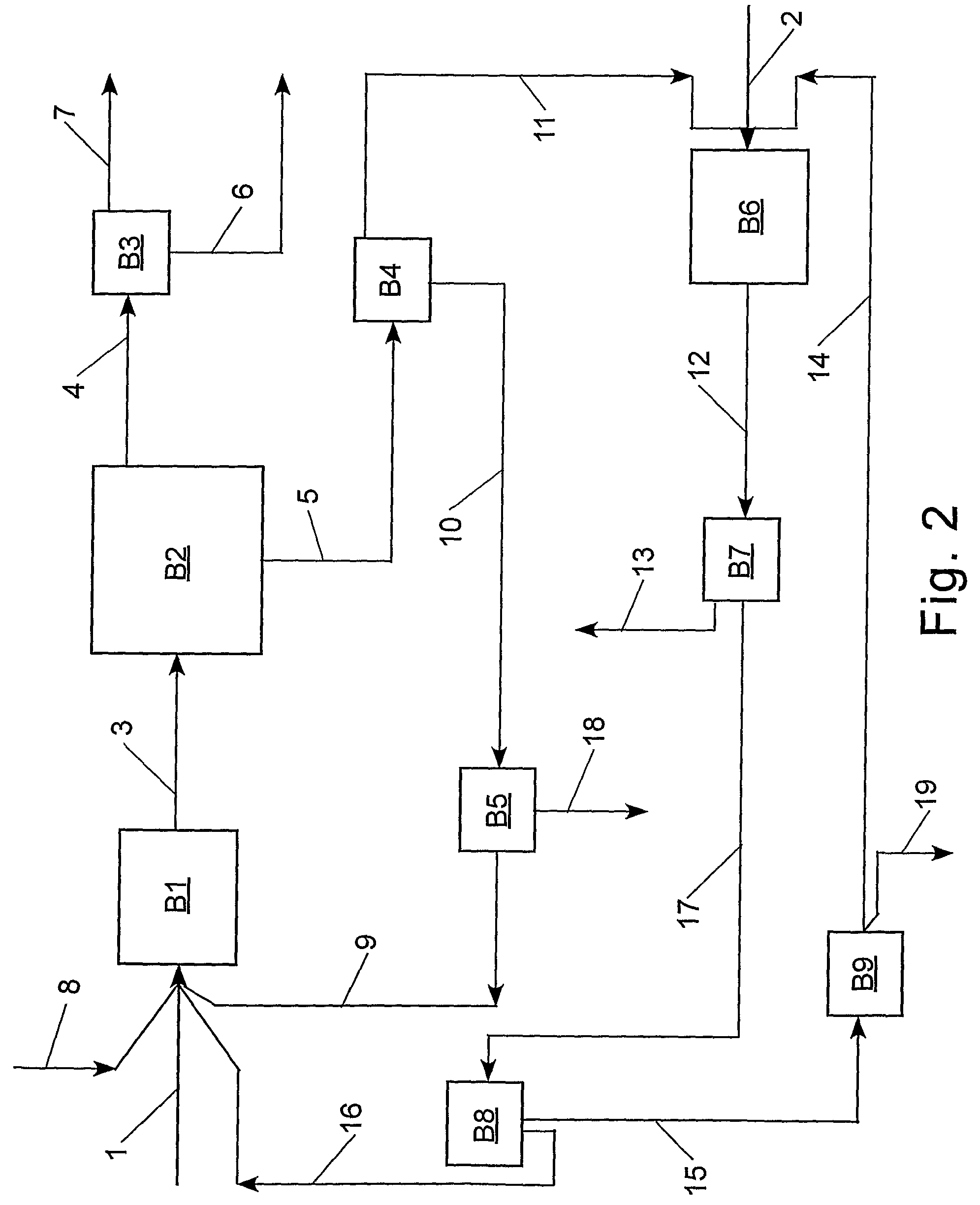

Metathesis process for preparing an alpha, omega-functionalized olefin

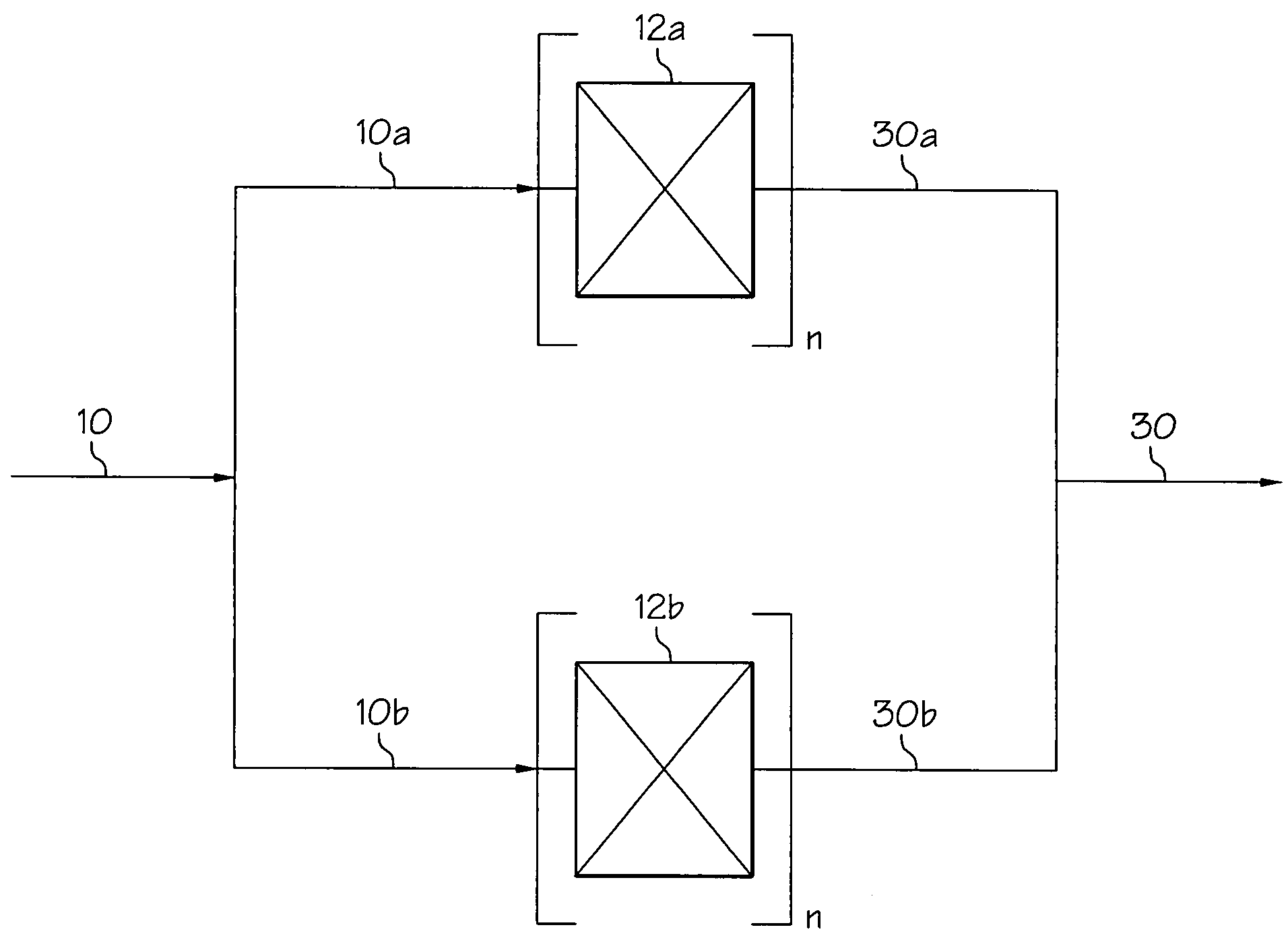

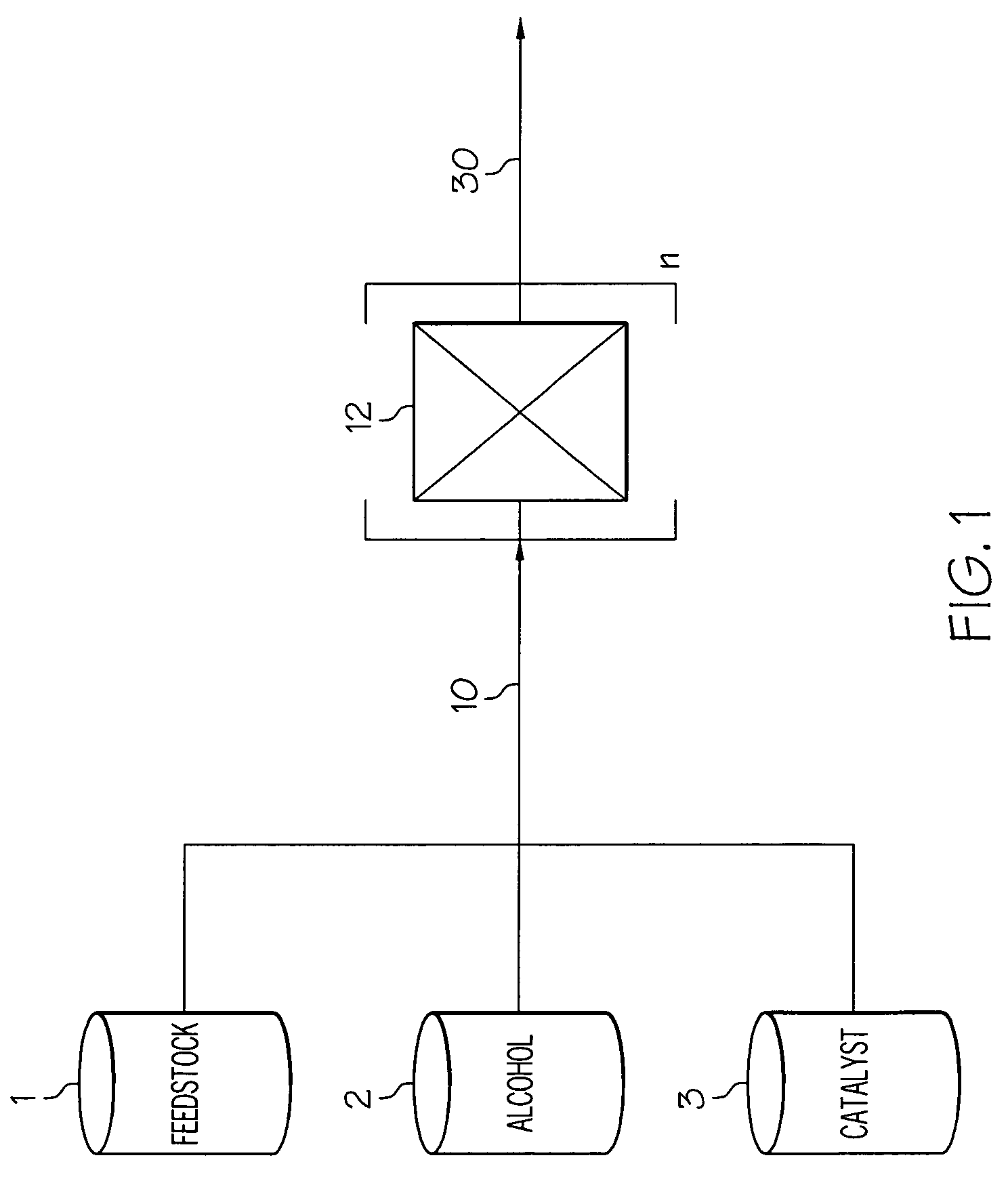

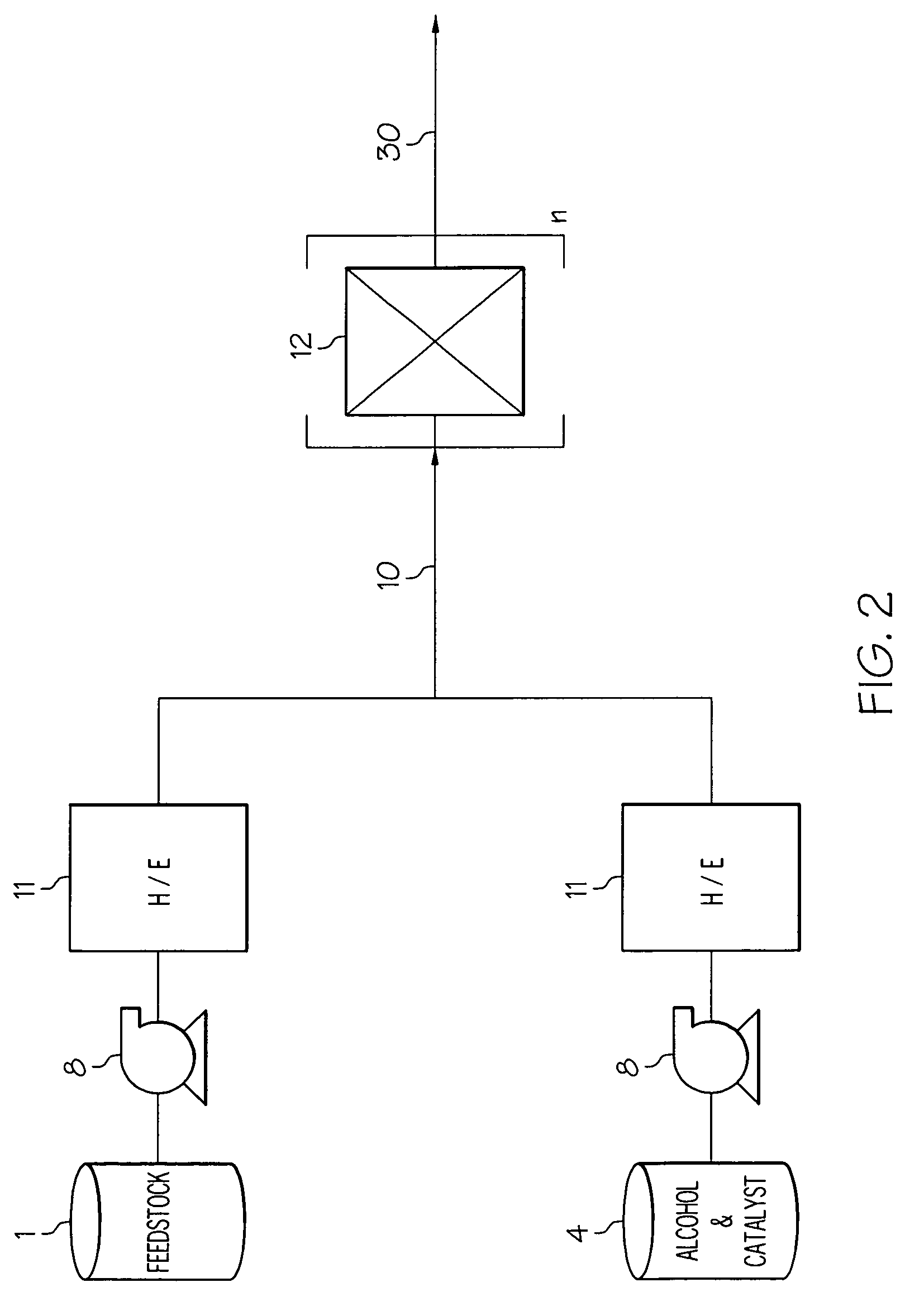

InactiveUS7812185B2Shorten the lengthImprove turnover rateOrganic compound preparationCarboxylic acid esters preparationReaction zoneAlpha-olefin

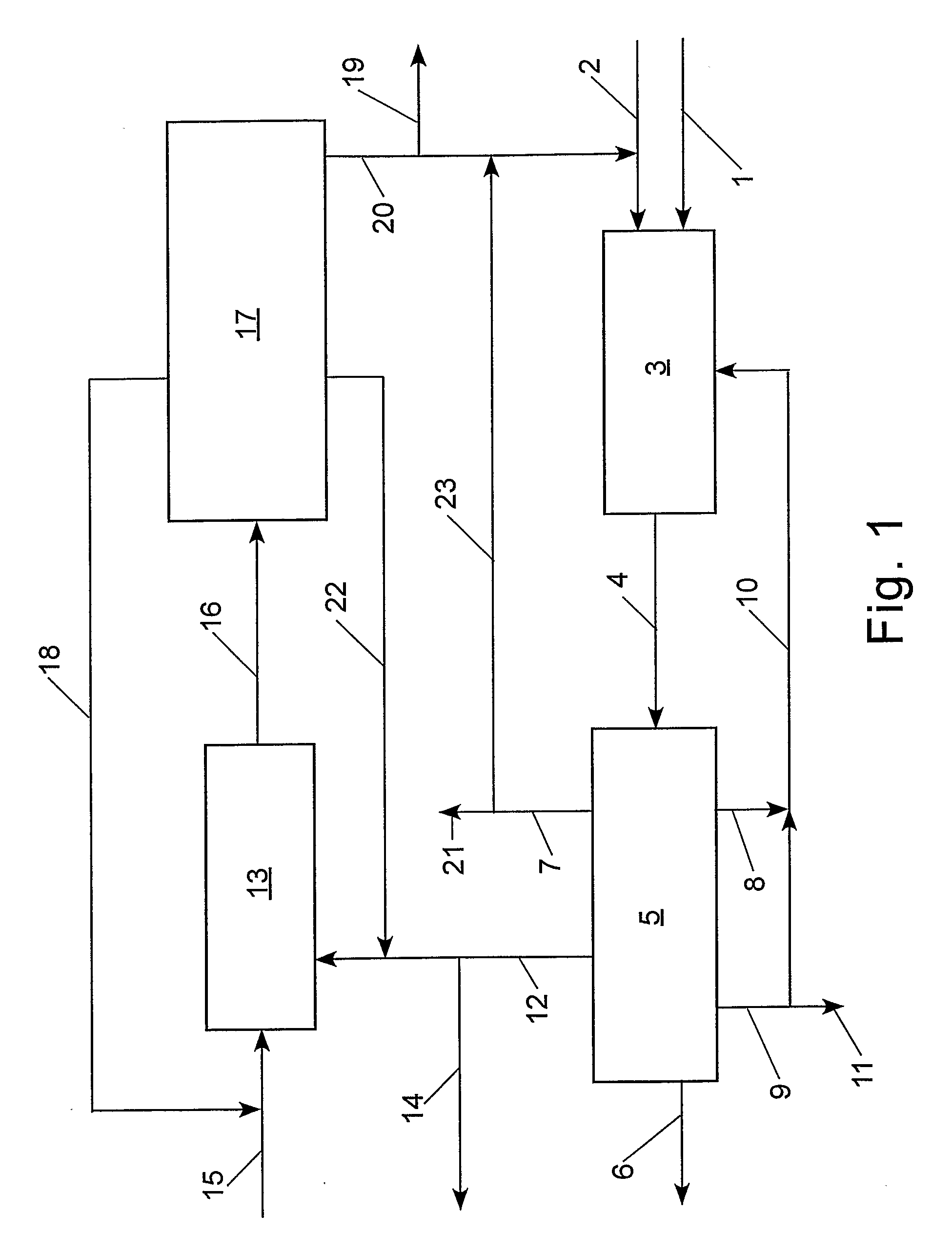

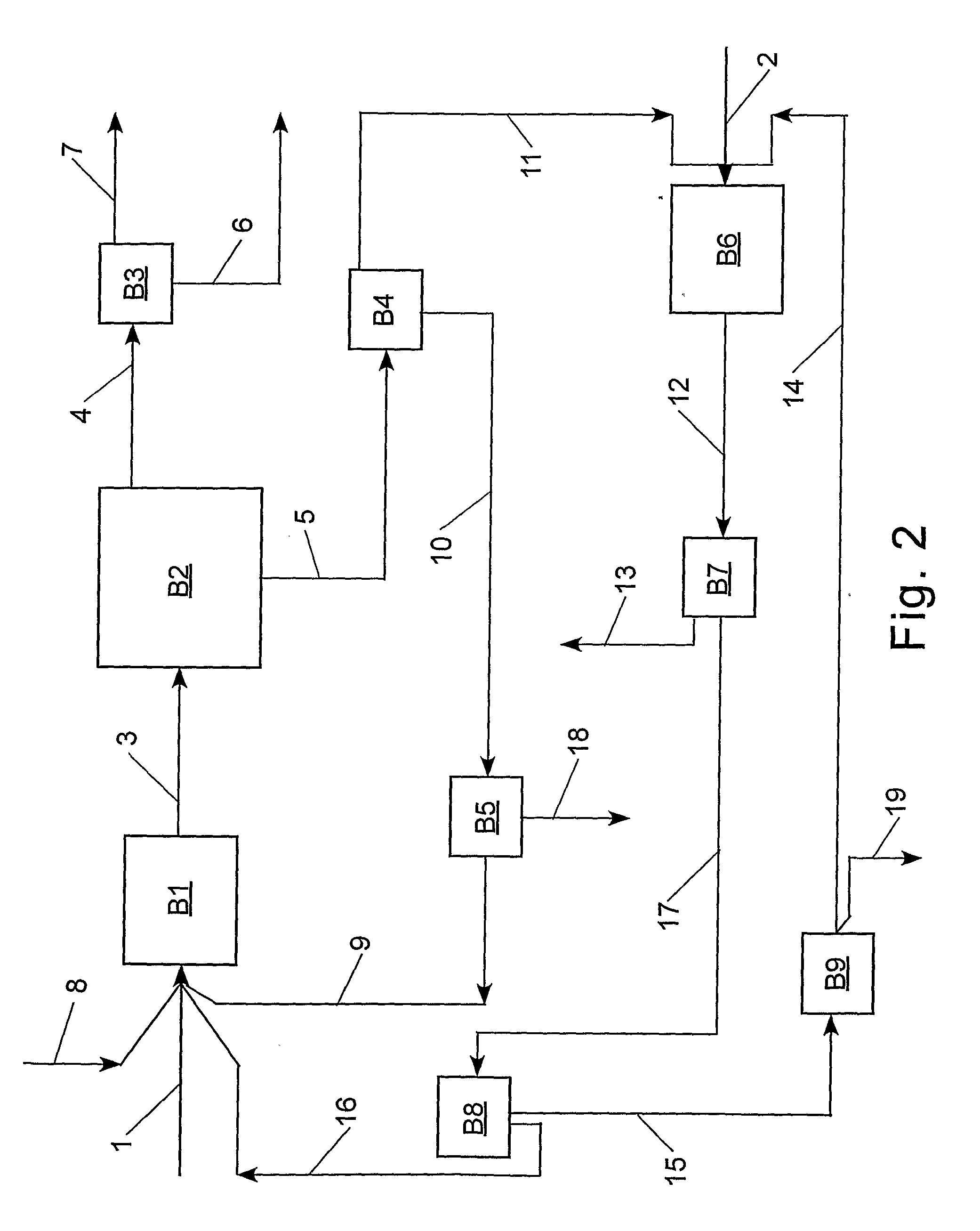

A cross-metathesis process for preparing an α,ω-functionalized olefin, such as methyl 9-decenoate, and an α-olefin having three or more carbon atoms, such as 1-decene. The process involves contacting in a first reaction zone an α-functionalized internal olefin, such as methyl oleate, and an α-olefinic monomer having three or more carbon atoms, such as 1-decene, with a first metathesis catalyst to prepare an effluent stream containing the α,ω-functionalized olefin, such as methyl 9-decenoate, an unfunctionalized internal olefin, such as 9-octadecene, unconverted reactant olefins, and optionally, an α,ω-difunctionalized internal olefinic dimer, such as dimethyl 9-octadecen-1,18-dioate; separating said effluent streams; then contacting in a second reaction zone the unfunctionalized internal olefin with ethylene in the presence of a second metathesis catalyst to obtain a second product effluent containing the α-olefinic monomer having three or more carbon atoms; and cycling a portion of the α-olefinic monomer stream(s) to the first zone.

Owner:DOW GLOBAL TECH LLC

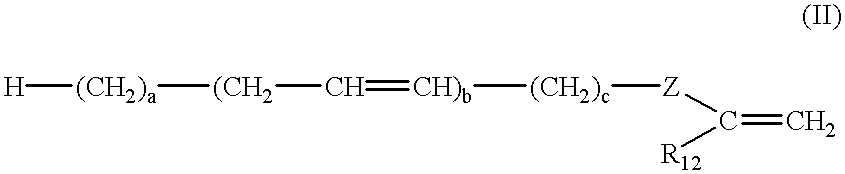

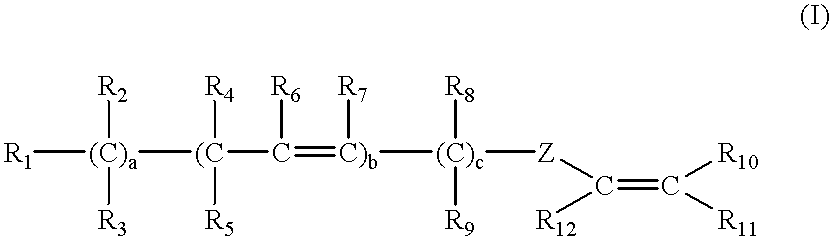

Latex compositions containing ethylenically unsaturated esters of fatty compounds and applications thereof

Novel latex or emulsion compositions containing internally plasticizing and crosslinkable monomers derived from traditional semi-drying or non-drying oils are disclosed and claimed. The monomers are ethylenically unsaturated derivatives of long-chain olefinic compounds. Preferred embodiments include latex formed from acrylate or methacrylate esters of fatty alcohols. A process for the synthesis of the latex composition is also disclosed, which involves (a) polymerization of the ethylenically unsaturated derivatives of a long-chain olefinic compound in an aqueous phase with at least one other copolymerizable monomer; and (b) blending of so formed polymer with at least one drier and a surfactant to form the novel latex or emulsion compositions. These compositions form films at low minimum film forming temperatures (MFT) ranging from -5 to 10° C. and cure to above ambient glass transition (Tg) polymers without the use of traditional organic cosolvents which contribute to environmental pollution via volatile organic compounds (VOCs) emissions. These compositions are therefore useful in waterborne coatings, contact and pressure sensitive adhesives, and inks.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI +1

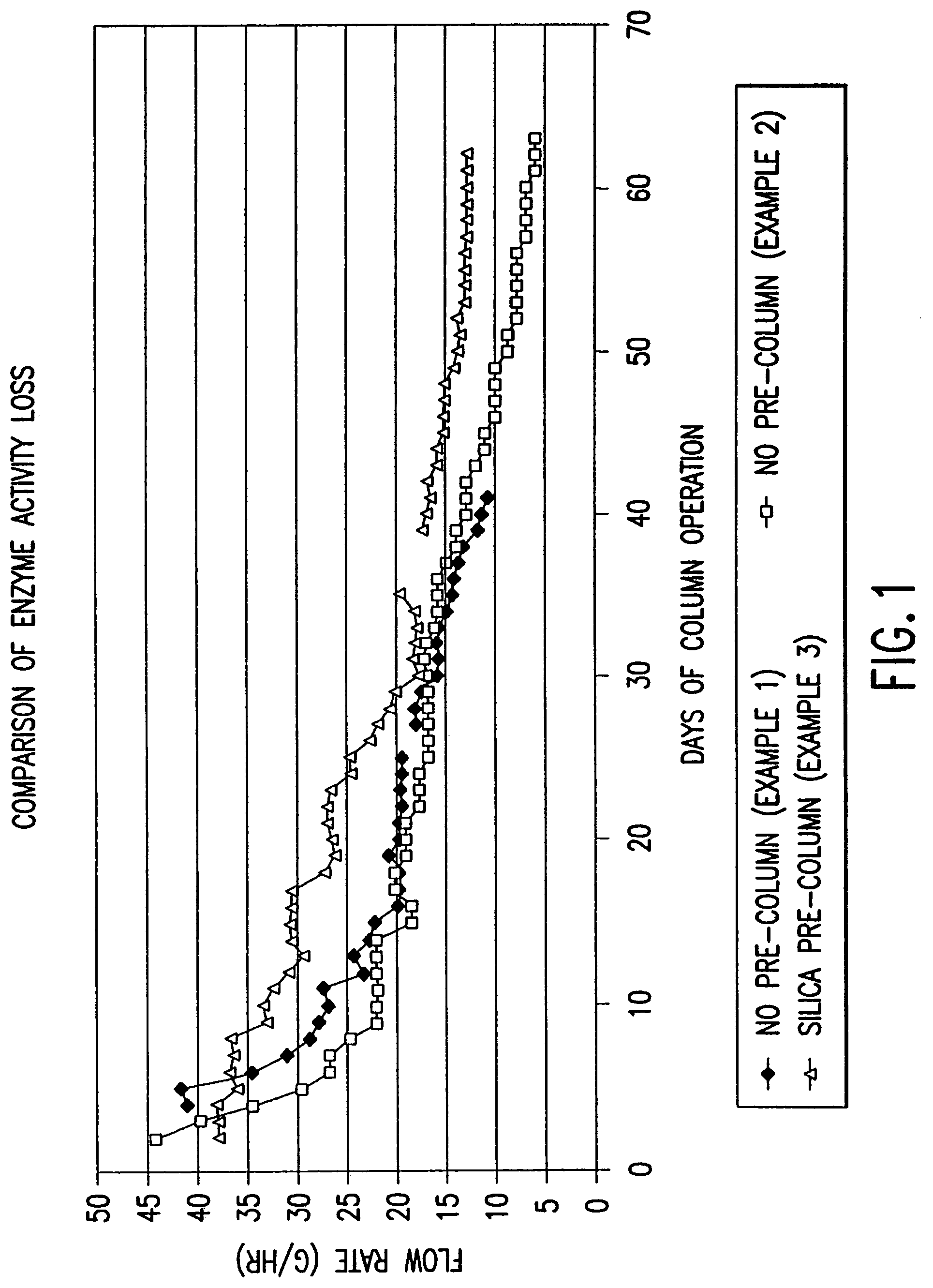

Method for producing fats or oils

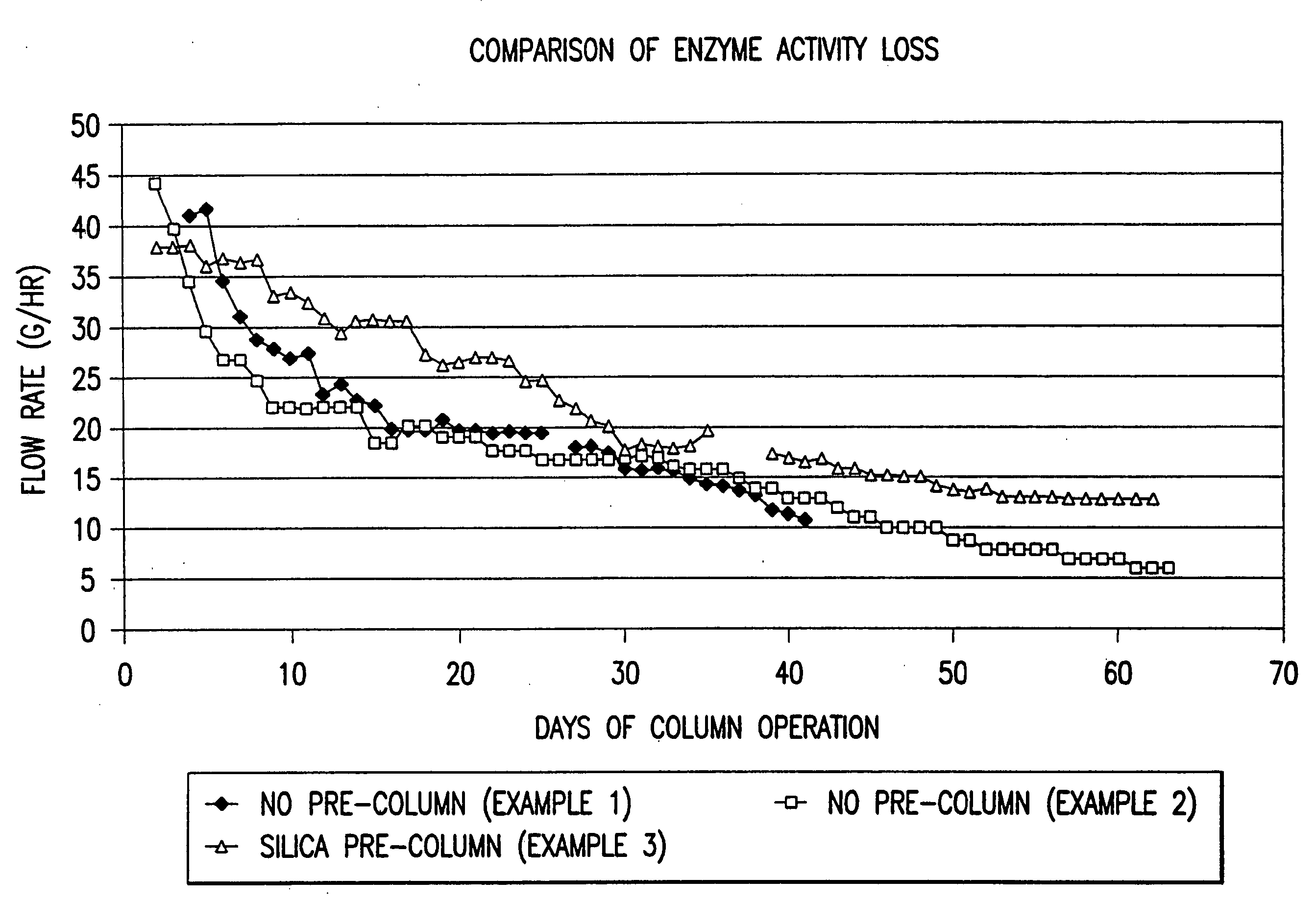

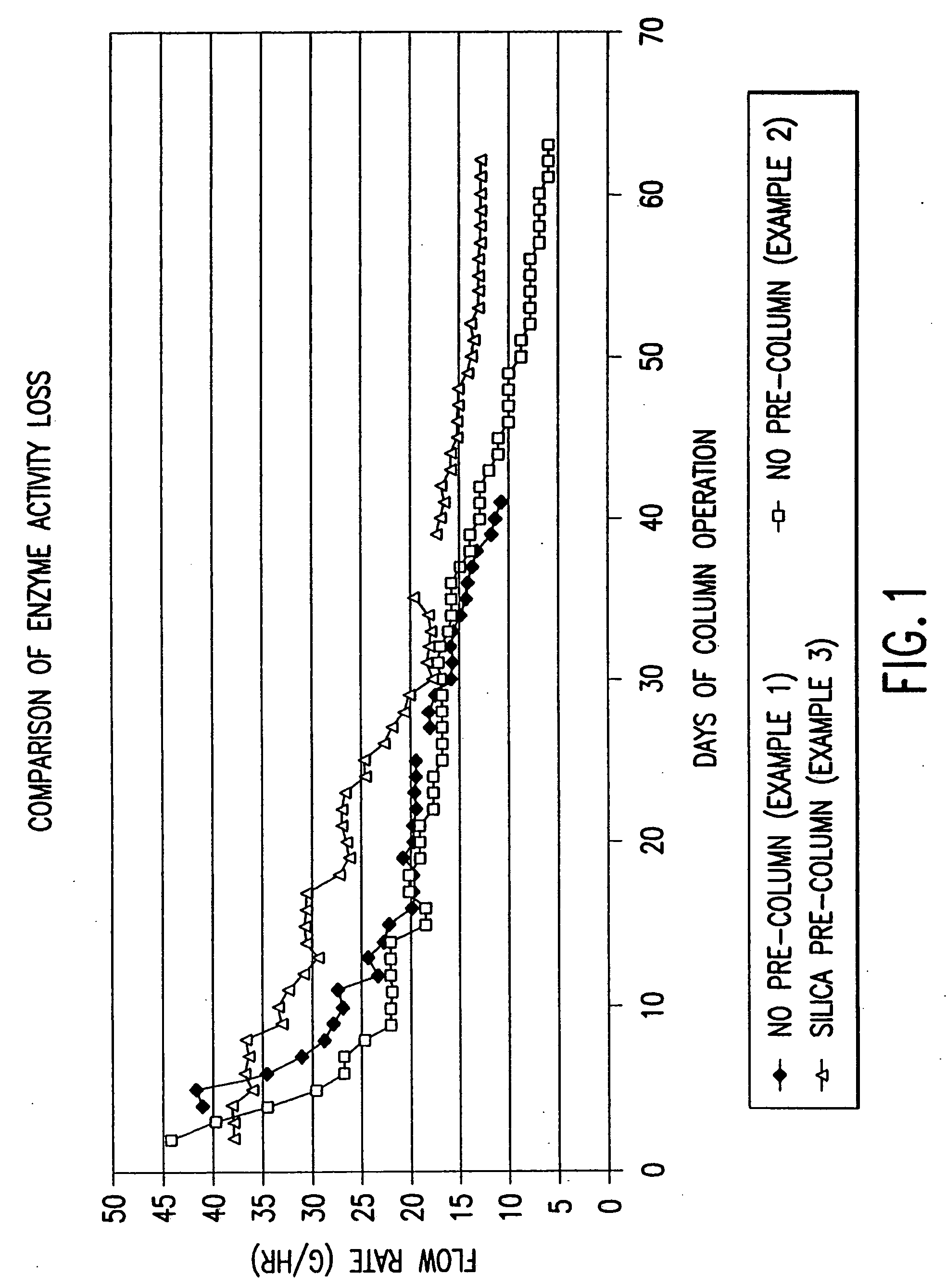

ActiveUS20050014237A1Extended half-lifeFatty oils/acids recovery from wasteFatty acid esterificationTransesterificationEnzyme

The present invention is directed to improving productivity of an enzymatic method for making esterified, transesterified or interesterified products. Specifically, a method that can greatly improve the productivity of enzymatic transesterification or esterification by deodorization alone, or by deodorization and purification of the initial substrate to extend the useful life of the enzyme is disclosed.

Owner:ARCHER DANIELS MIDLAND CO

Process for the preparation of fatty acid methyl ester from triglyceride oil by transesterification

InactiveUS7666234B2Speed up the processFatty oils/acids recovery from wasteFatty acid esterificationTransesterificationTriglyceride

The present invention relates to an improved process for the preparation of biodiesel from triglyceride oils through transesterification, particularly the fatty acid methyl ester of oil mechanically expelled from whole seeds of Jatropha curcas, a plant with potential for cultivation on wastelands in India and other countries, all unit operations being carried out at ambient temperature.

Owner:COUNCIL OF SCI & IND RES

Metathesis Process For Preparing An Alpha, Omega-Functionalized Olefin

InactiveUS20080228017A1Shorten the lengthImprove turnover rateOrganic compound preparationCarboxylic acid esters preparationReaction zoneAlpha-olefin

A cross-metathesis process for preparing an α,ω-functionalized olefin, such as methyl 9-decenoate, and an α-olefin having three or more carbon atoms, such as 1-decene. The process involves contacting in a first reaction zone an α-functionalized internal olefin, such as methyl oleate, and an α-olefinic monomer having three or more carbon atoms, such as 1-decene, with a first metathesis catalyst to prepare an effluent stream containing the α,ω-functionalized olefin, such as methyl 9-decenoate, an unfunctionalized internal olefin, such as 9-octadecene, unconverted reactant olefins, and optionally, an α,ω-difunctionalized internal olefinic dimer, such as dimethyl 9-octadecen-1,18-dioate; separating said effluent streams; then contacting in a second reaction zone the unfunctionalized internal olefin with ethylene in the presence of a second metathesis catalyst to obtain a second product effluent containing the α-olefinic monomer having three or more carbon atoms; and cycling a portion of the α-olefinic monomer stream(s) to the first zone.

Owner:DOW GLOBAL TECH LLC

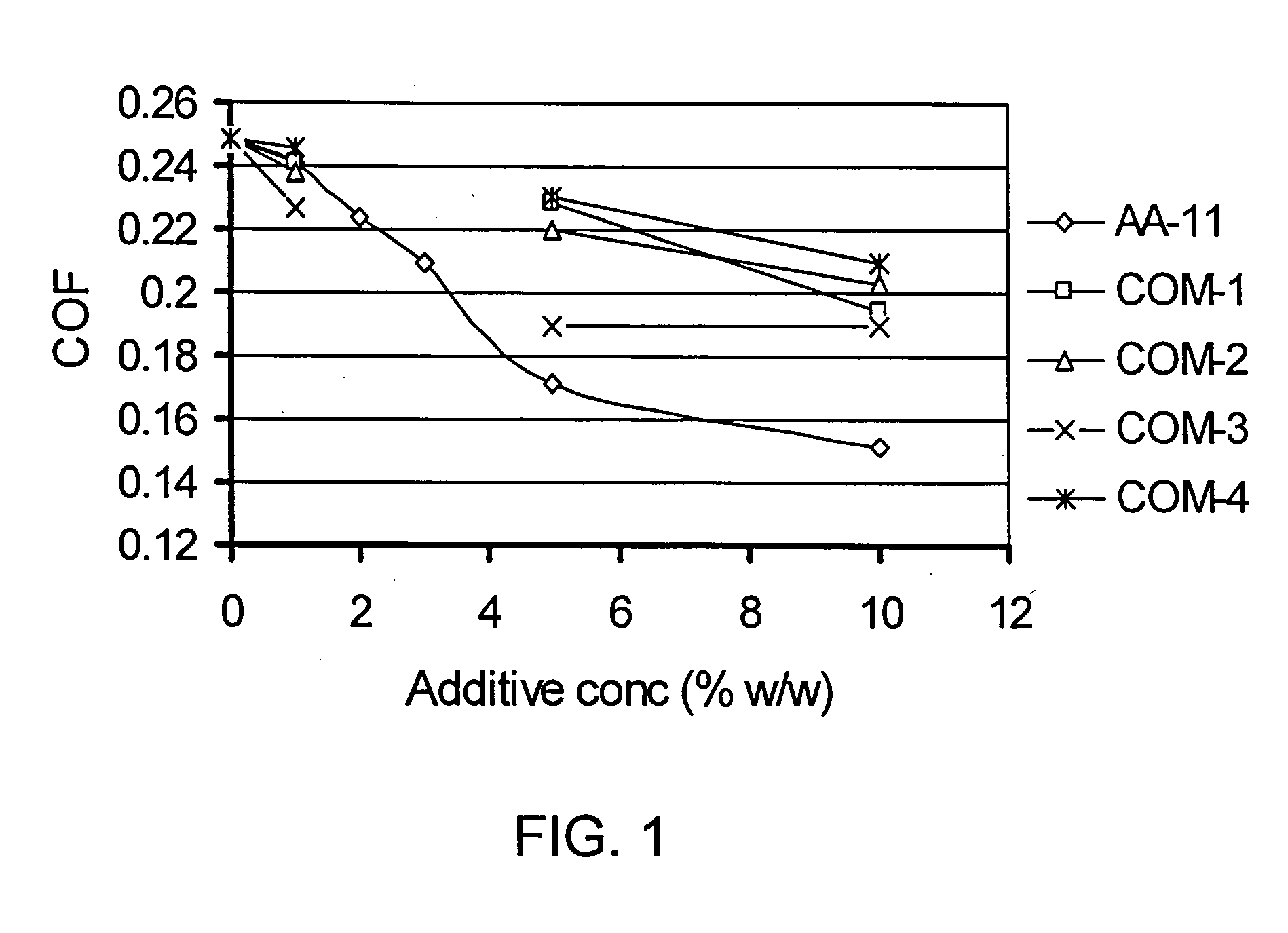

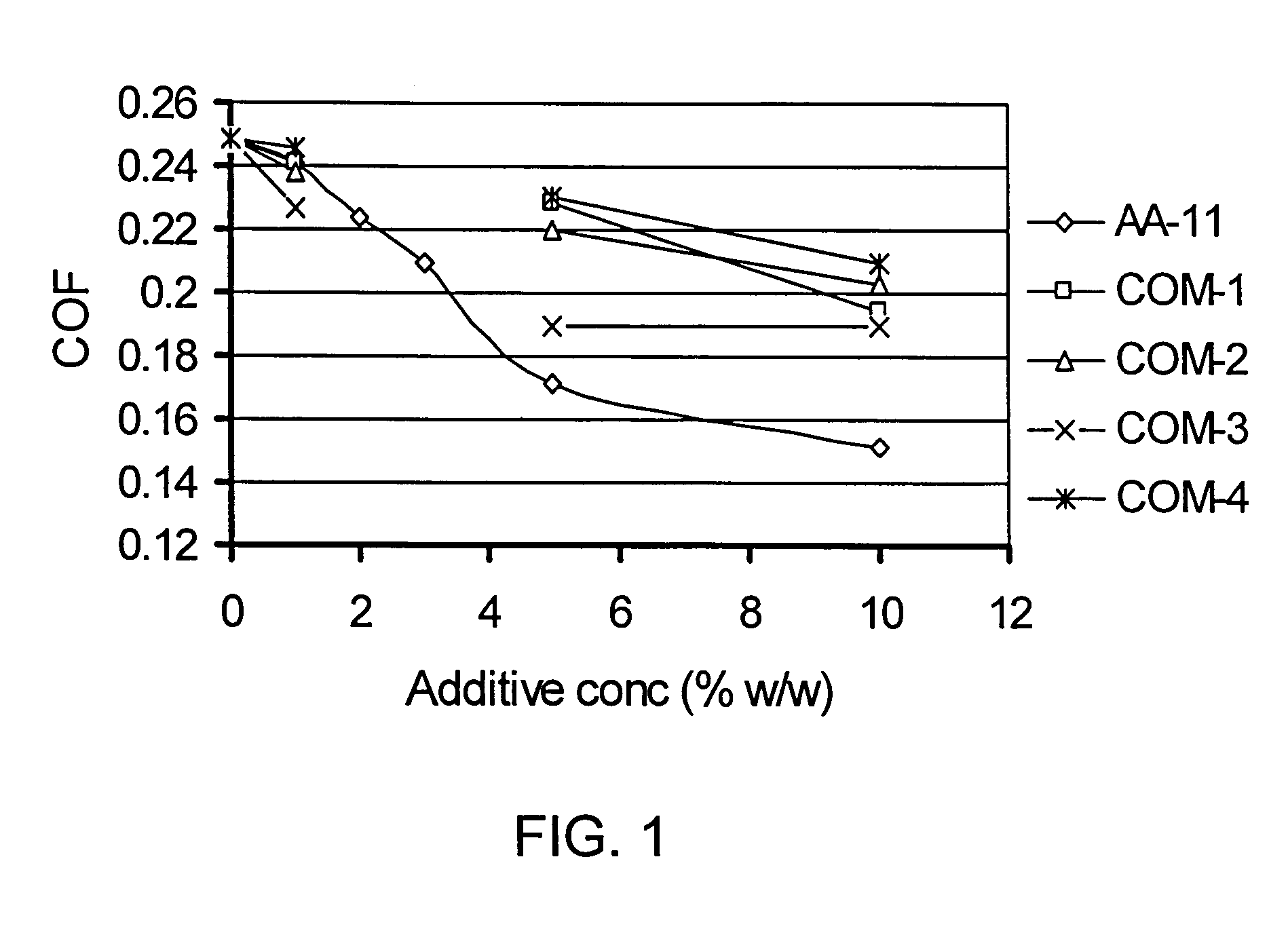

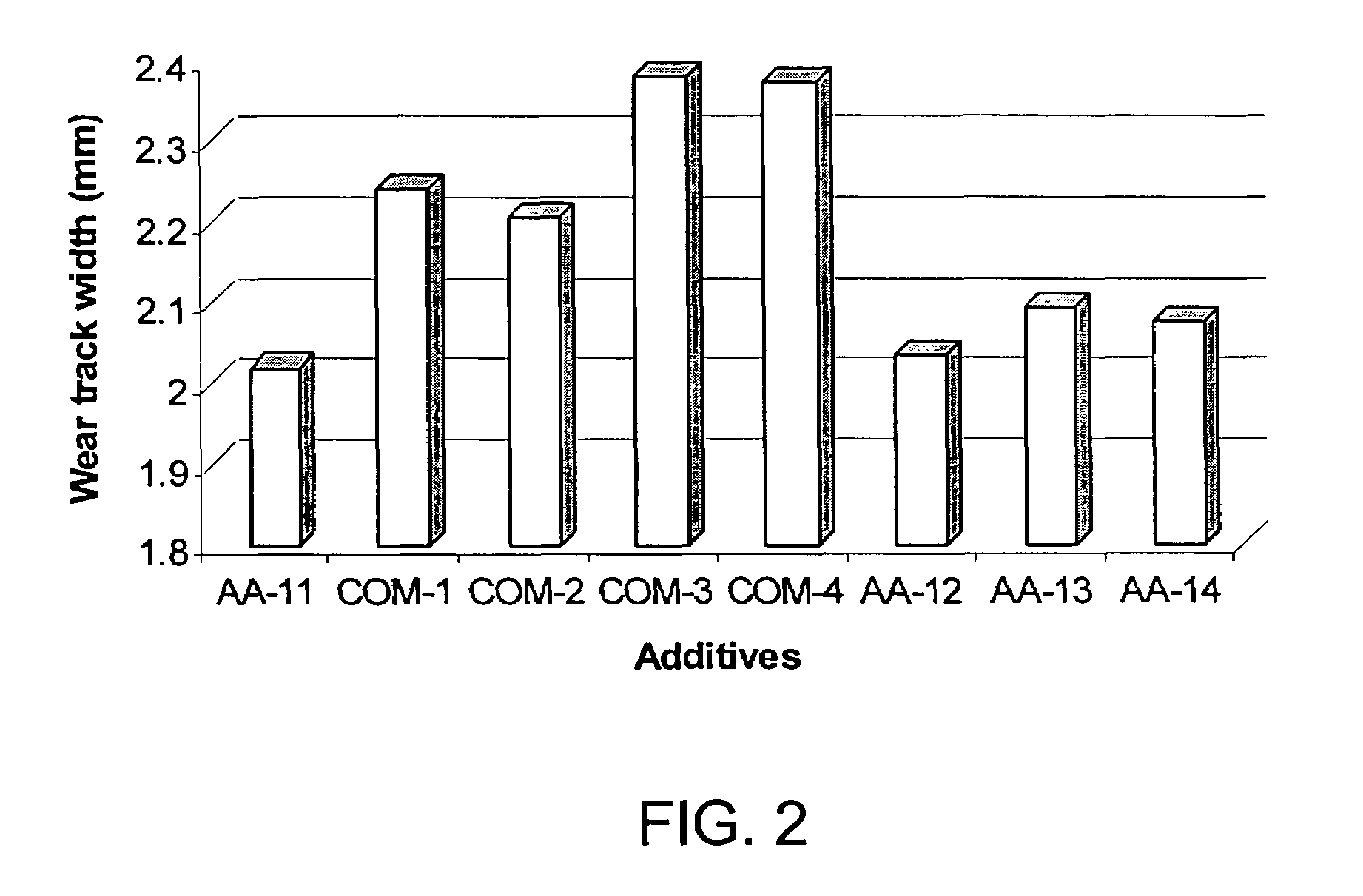

Poly(hydroxy thioether) vegetable oil derivatives useful as lubricant additives

InactiveUS20060009365A1Expand the marketReduce demandOrganic compound preparationSurface-active detergent compositionsThiolVegetable oil

A novel class of chemically-modified vegetable oils is prepared by reacting epoxidized triglyceride oils with thiols. The resultant poly(hydroxy thioether) derivatives have utility as antiwear / antifriction additives for environmentally-friendly industrial oils and automotive applications.

Owner:US SEC AGRI +1

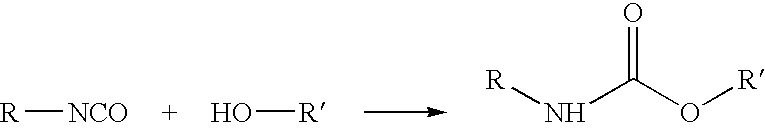

Polyol fatty acid polyesters process and polyurethanes therefrom

InactiveUS7125950B2Overcome deficienciesFatty oils/acids recovery from wasteSugar derivativesPolyesterNatural source

A solvent-free process for making a polyol fatty acid polyester composition useful for preparation of polyurethanes is described. These compositions are preferably made by reaction of a natural oil (from plant or animal) with a multi-functional hydroxyl compound derived from a natural source, such as sorbitol, in presence of an alkali metal salt or base such as potassium hydroxide as a catalyst which also acts to saponify the reaction mixture. The hydroxyl content of the prepared composition depends on the amount of the multi-functional hydroxyl compound used in the preparation. In another embodiment, the hydroxyl groups of these compositions are reacted with an isocyanate, such as the polymeric diphenylmethane diisocyanate (also known as 4,4′-diphenyl methane diisocyanate, or MDI) to form polyurethanes in a conventional manner.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

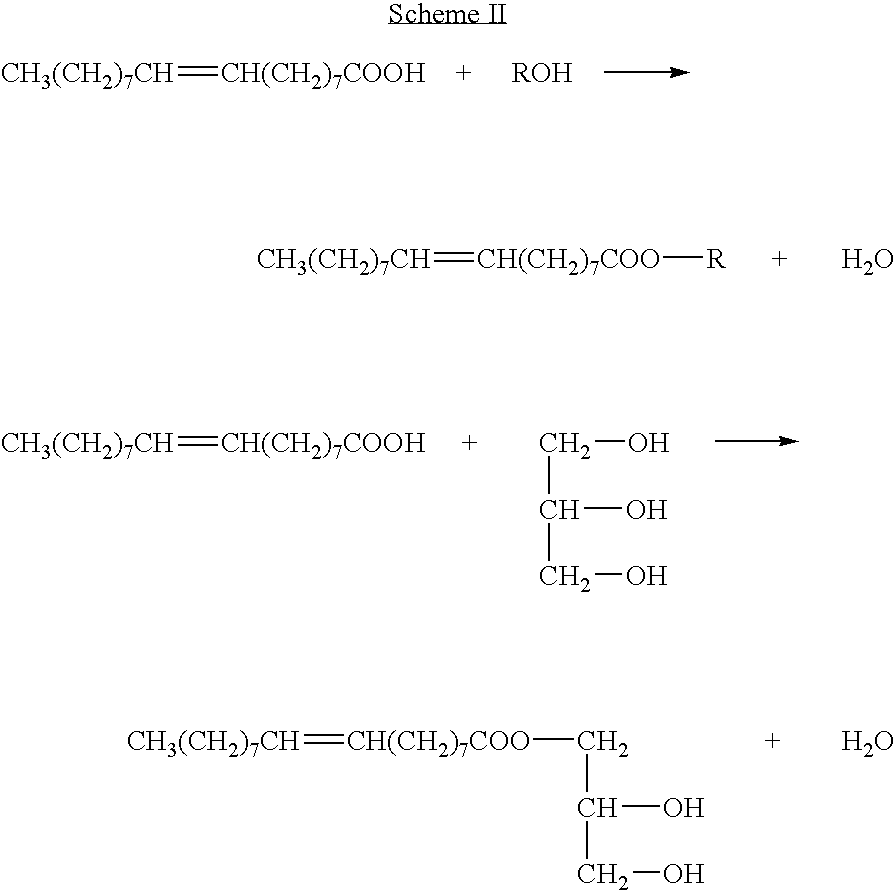

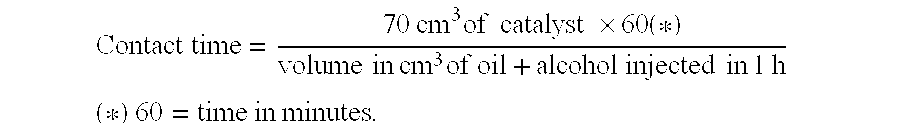

Process for transesterification of vegetable or animal oils using heterogeneous catalysts based on titanium, zirconium or antimony and aluminium

InactiveUS20050266139A1Possible formFatty acid esterificationPreparation by ester-hydroxy reactionHomogeneous catalysisTitanium oxide

A novel process is described for producing esters of linear monocarboxylic acids containing 6 to 26 carbon atoms, by reacting vegetable or animal oils, neutral or otherwise, with monoalcohols containing 1 to 18 carbon atoms in the presence of a catalyst selected from: mixtures of titanium oxide and alumina having formula: (TiOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y, representing the weight ratio of the two oxides, has a value of 0.005 to 0.995; mixtures of zirconium oxide and alumina having formula: (ZrOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y has a value of 0.005 to 0.995; and mixtures of antimony oxide and alumina having formula: (SbOx)y(Al2O3)1-y where x has the value 1.2 to 2.6 and y has a value of 0.005 to 0.995, in order to directly produce, in one or more steps, an ester for use as a fuel and a pure glycerin.

Owner:INST FR DU PETROLE

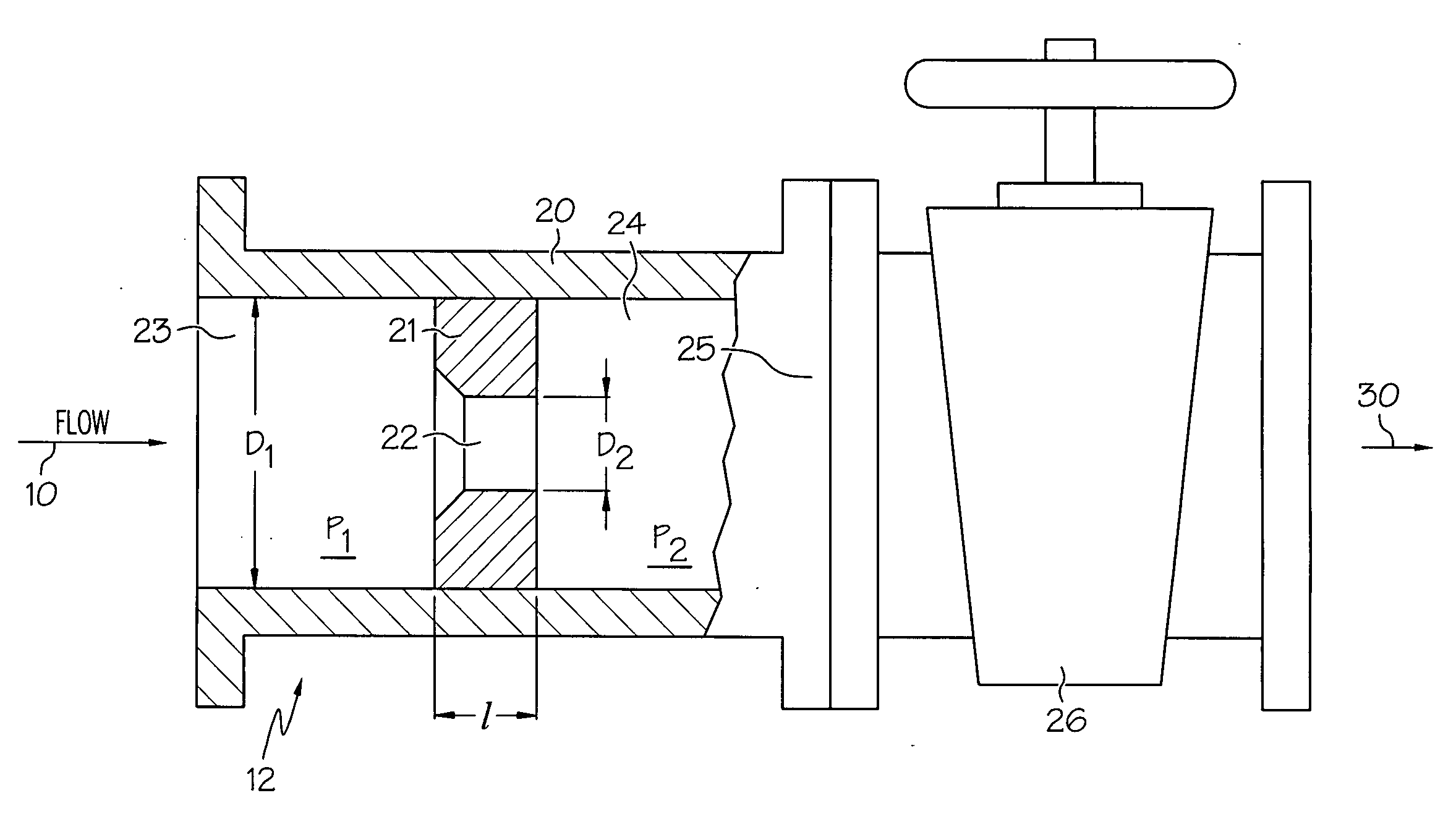

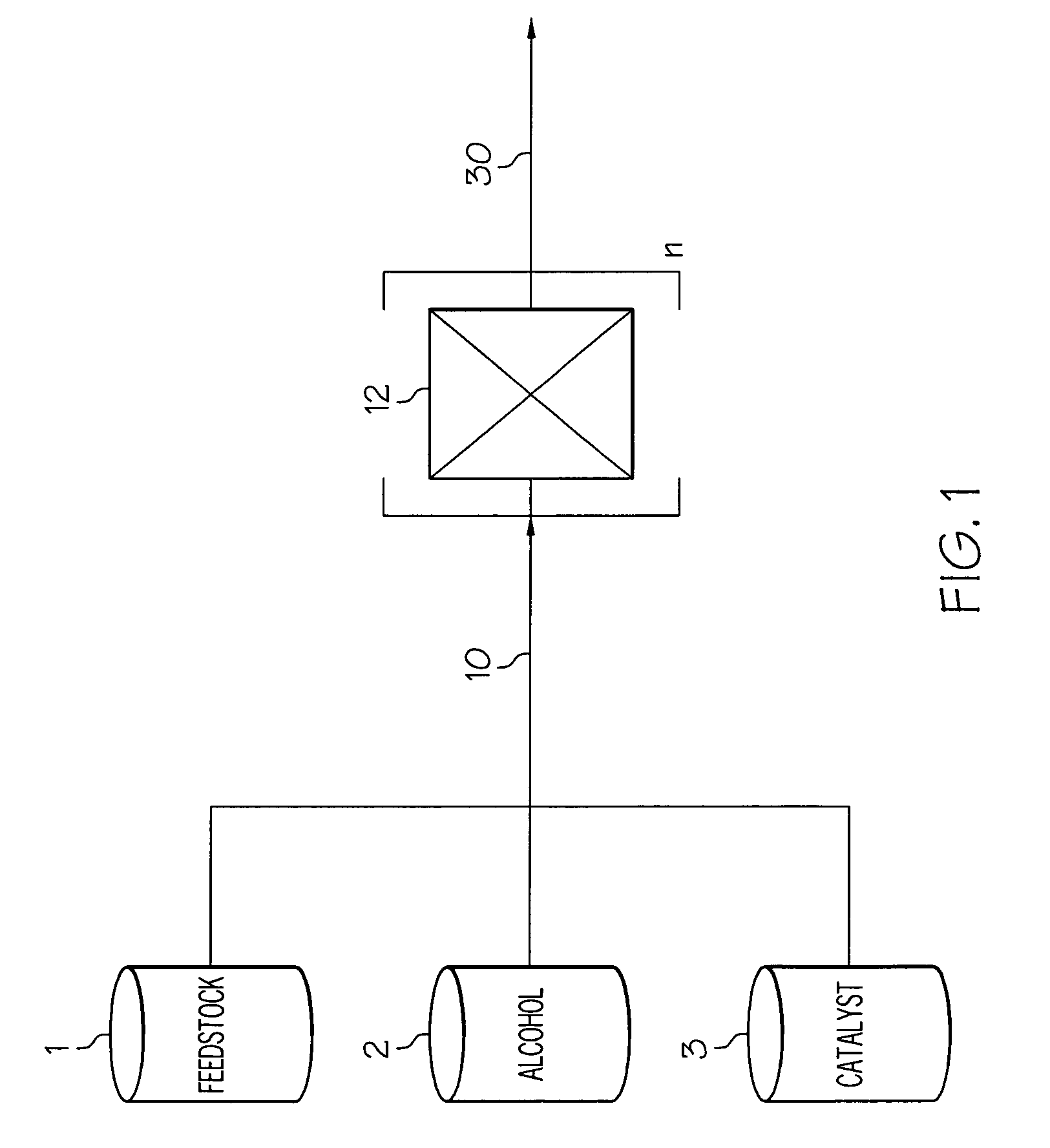

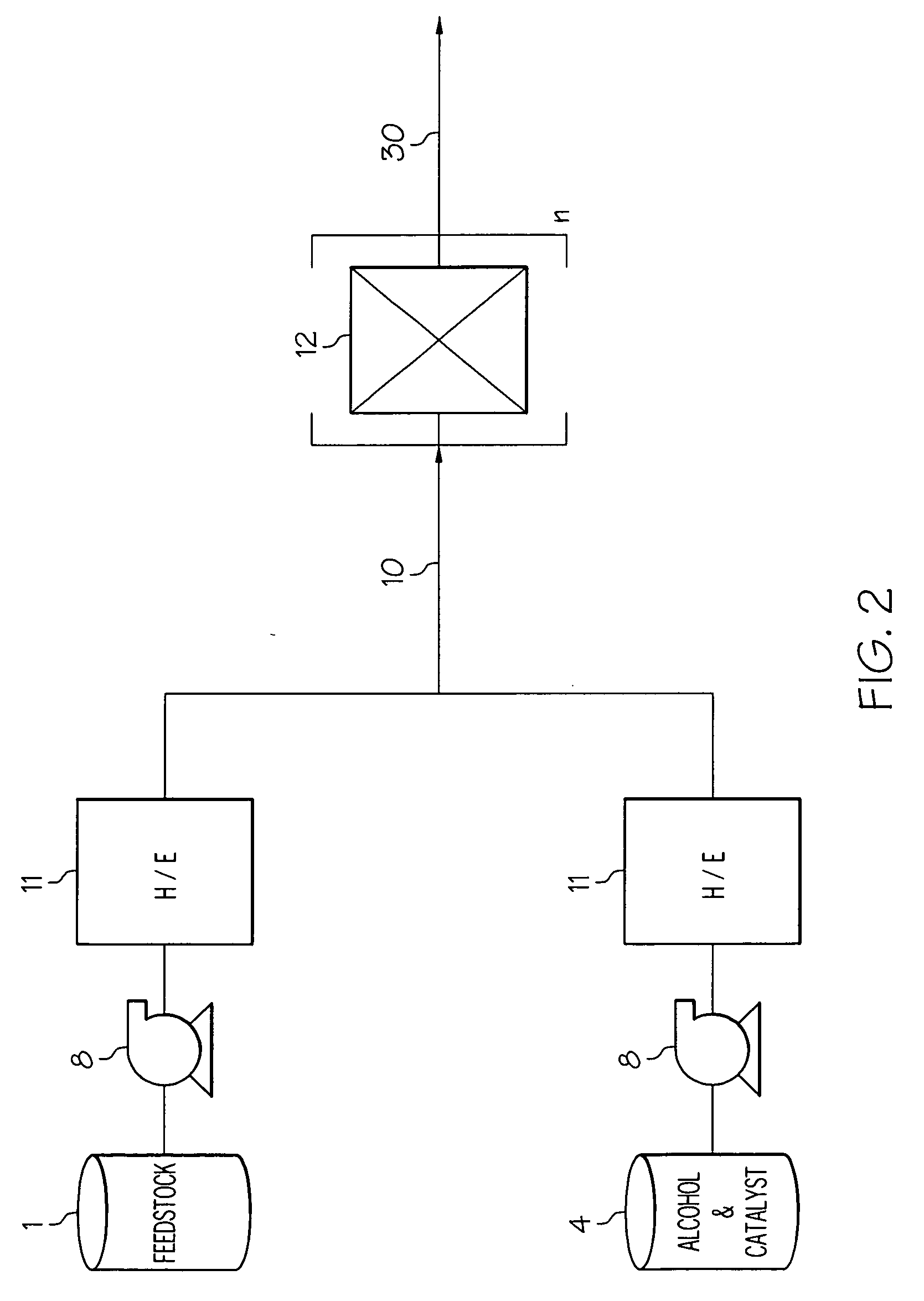

Apparatus and method for producing biodiesel from fatty acid feedstock

InactiveUS20090043118A1Improve conversion rateConversion rateFatty acid esterificationFatty acids production/refiningCavitationBiodiesel

A method comprising applying a controlled flow cavitation apparatus to a biodiesel production process in order to increase fatty acid alkyl ester yield. A feedstock comprising free fatty acids can be passed through a controlled flow cavitation apparatus at a velocity capable of generating a hydrodynamic cavitation zone where the free fatty acids can be esterified. One or more controlled flow cavitation apparatuses can be applied at various points of a biodiesel production process.

Owner:ARISDYNE STSTEMS INC

Polyol made from partialy hydrogenated, fully epoxidized natural oils

InactiveUS20110065821A1Low densityResistant to yellowingFatty acid hydrogenationFatty acid oxidationVegetable oilGram

A method is disclosed for making a polyol comprising: fully-epoxidizing a partially hydrogenated vegetable oil to obtain a fully-epoxidized vegetable oil derivative having an iodine value less than 4 g I2 / 100 gram, an EOC of from 4.0 to 5.7% and a Gardner color value of 2 or less; and then reacting the fully-epoxidized vegetable oil derivative with a ring opener to form a polyol having a hydroxyl number from 40 to 80 mg KOH / gram, a number average molecular weight of at least 1500 Daltons, a dynamic viscosity less than 10 pascal-seconds, and an EOC below 3.0 wt %.

Owner:CARGILL INC

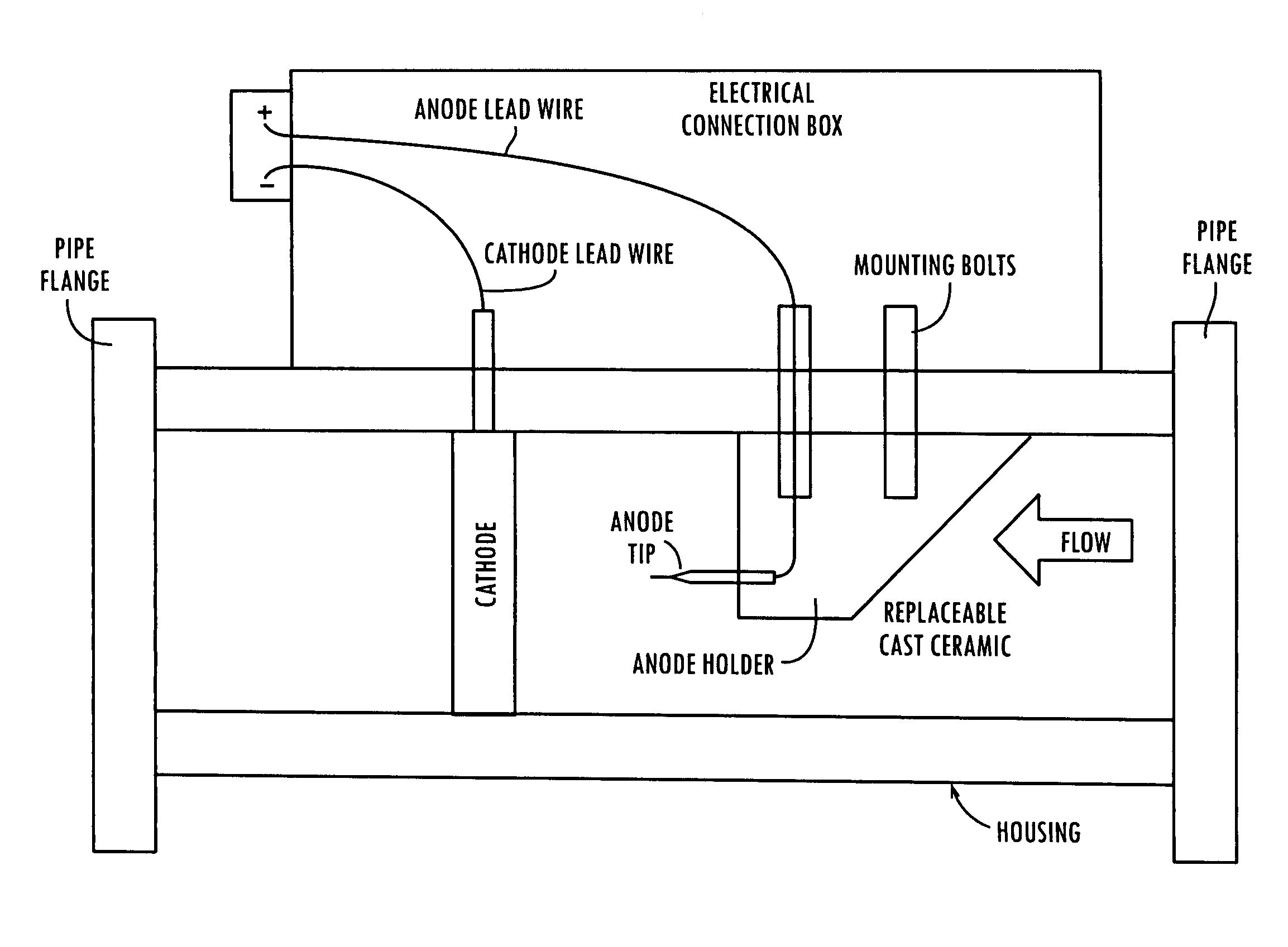

Method of electro-catalytic reaction to produce mono alkyl esters for renewable biodiesel

InactiveUS7722755B2Lowers NO<sub>X </sub>emissions without lowering the heat value of the fuelFatty oils/acids recovery from wasteAnodisationElectricityAcetic acid

Methods, systems, and devices are provided for synthesizing one or more chemical products from a renewable oil, comprising the step of flowing a fluid which comprises a renewable oil through a high voltage electrical field effective to catalyze a chemical reaction involving the renewable oil. Examples of renewable oils include vegetable oils, animal fats, bio-oils, and combinations thereof. In one embodiment, the fluid further comprises an alcohol mixed with the oil, and the chemical reaction produces biodiesel and an etherified glycerin. In one embodiment, the biodiesel is further reacted to produce acetic acid.

Owner:ECR TECH

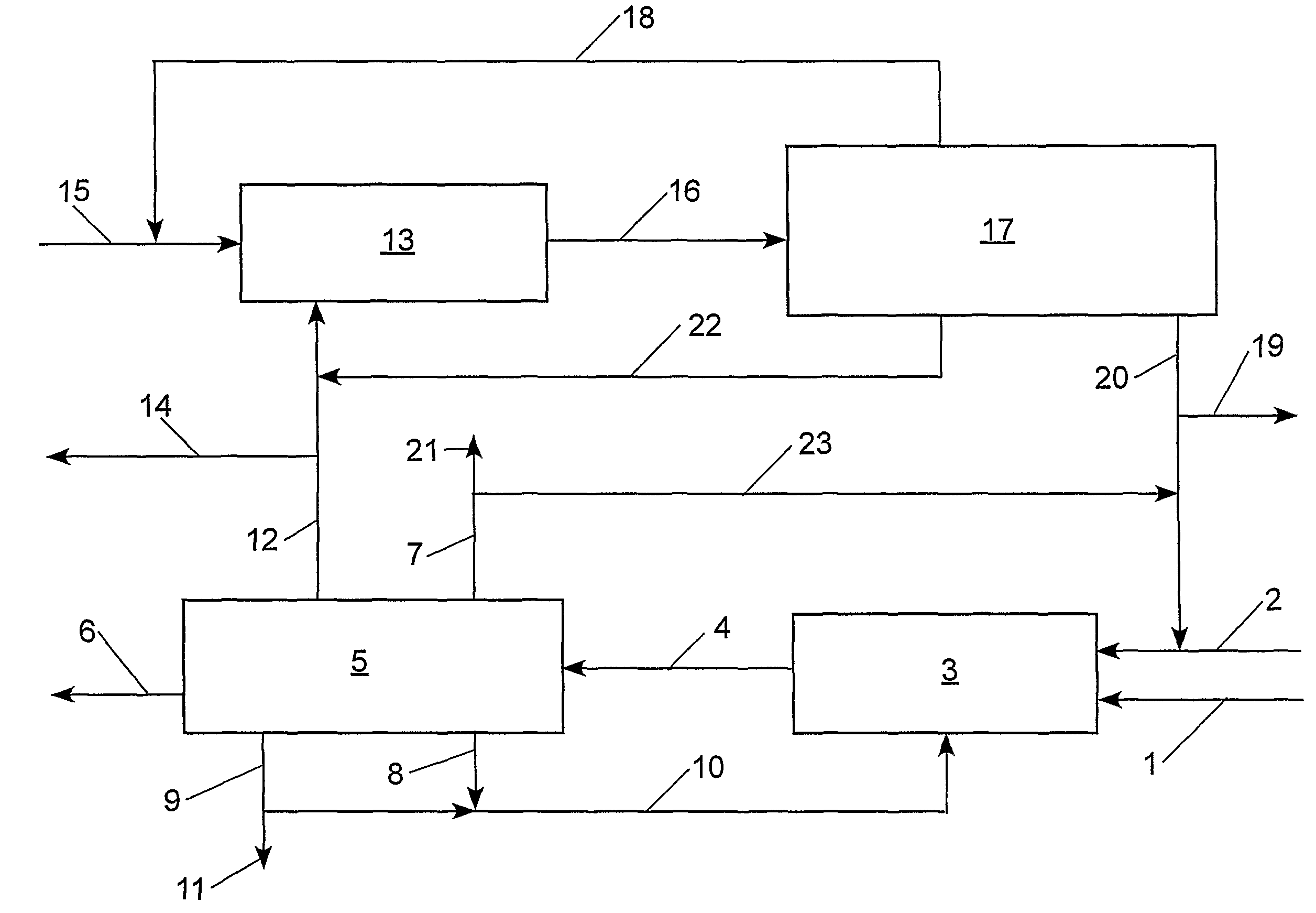

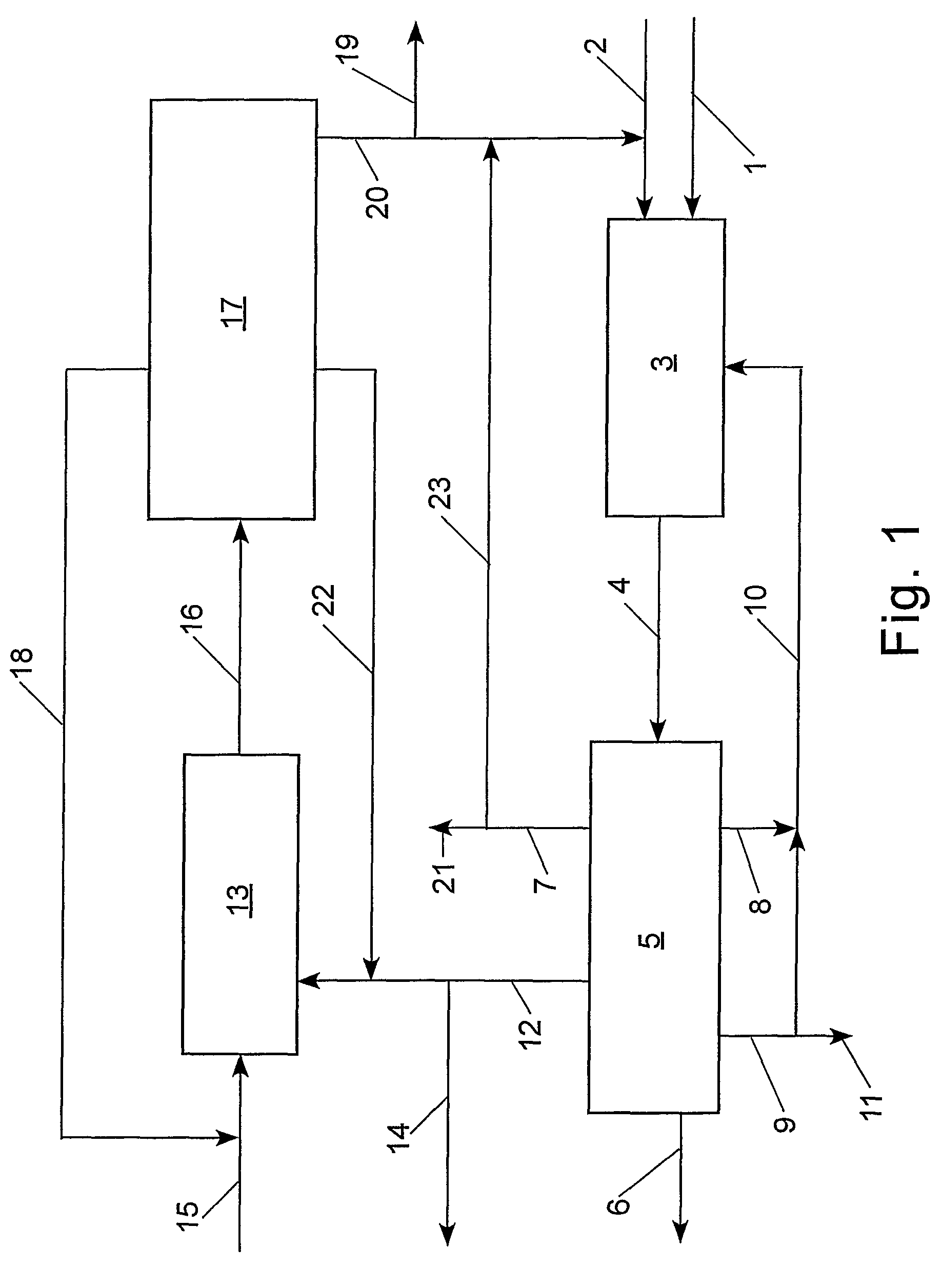

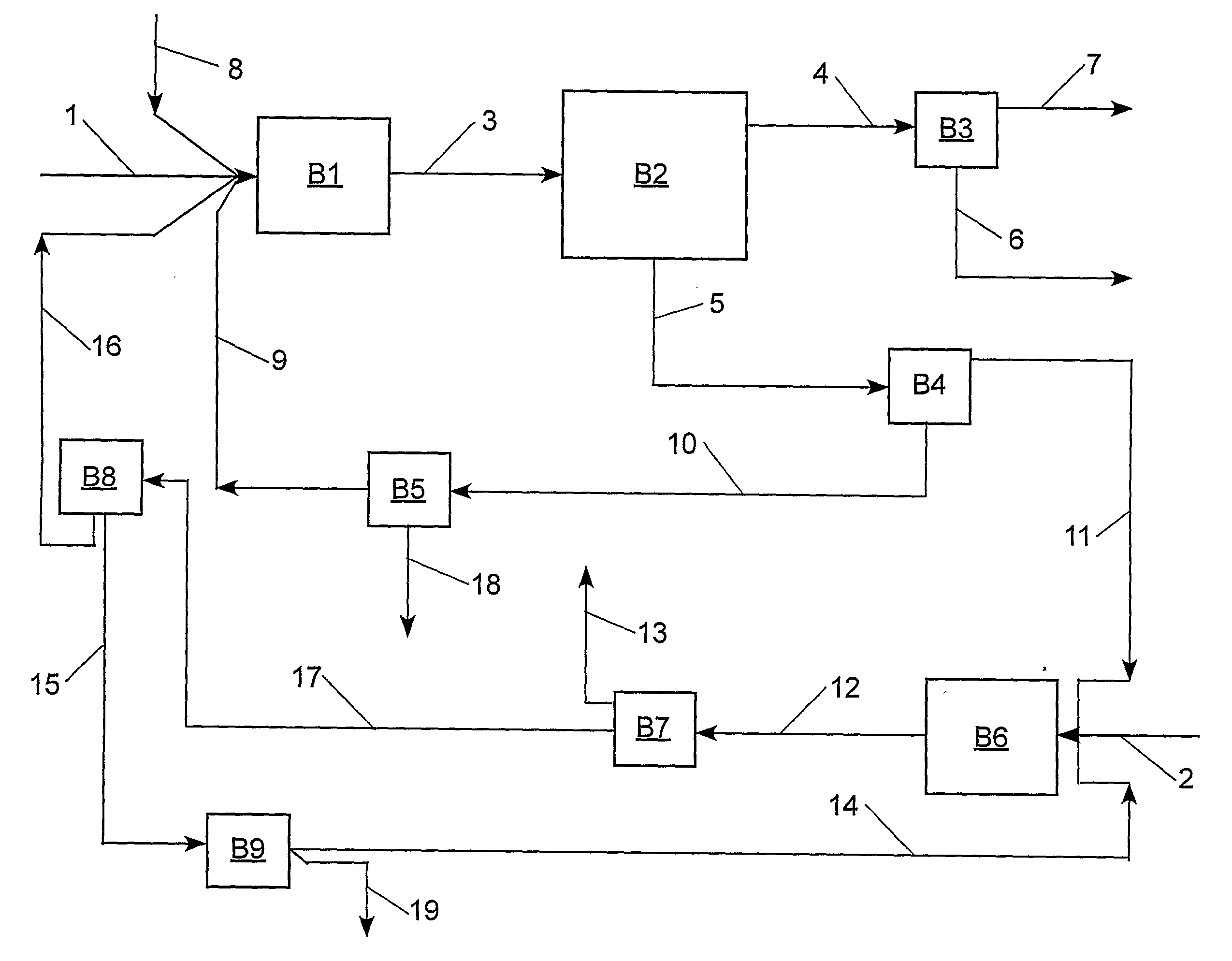

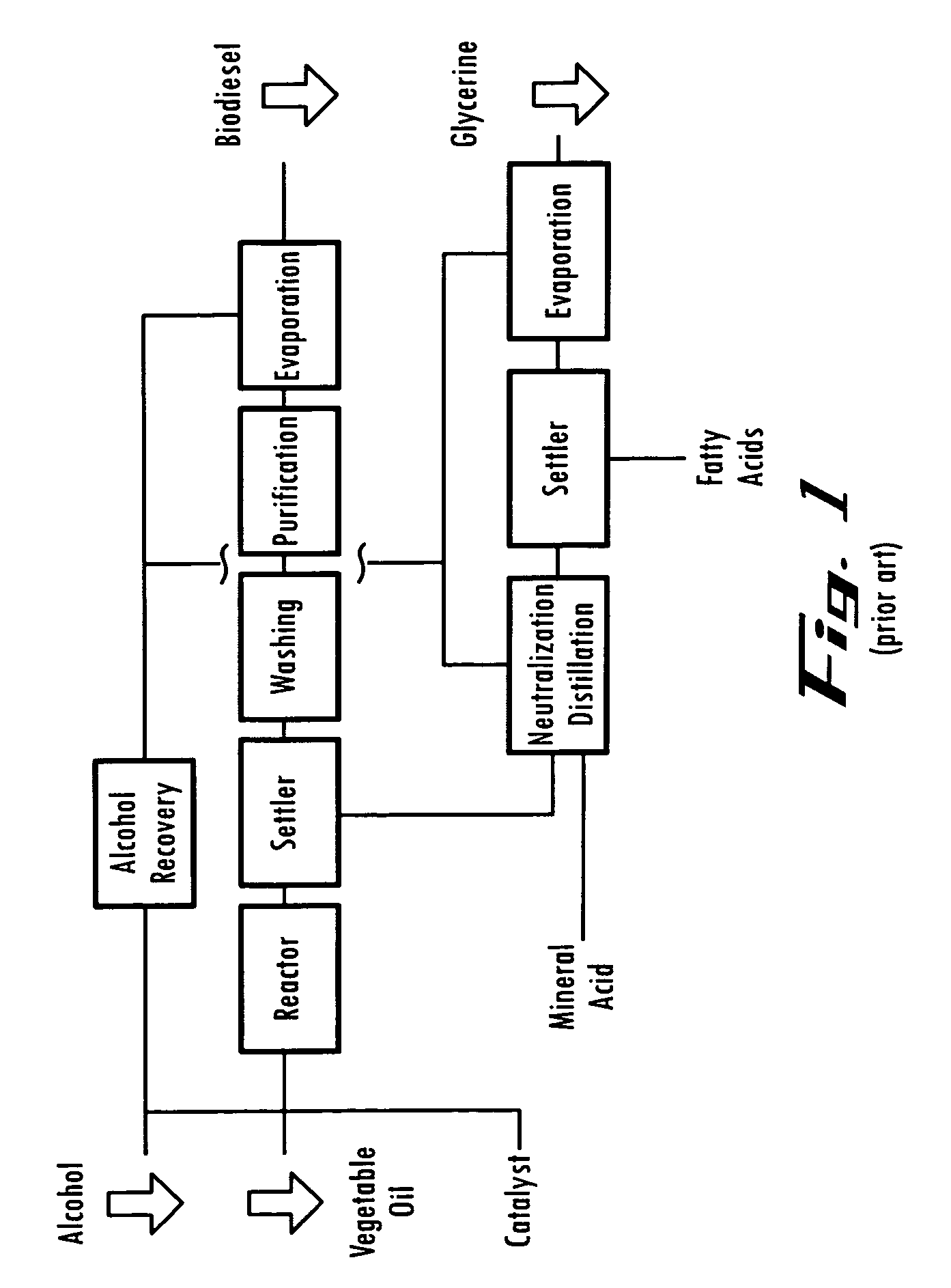

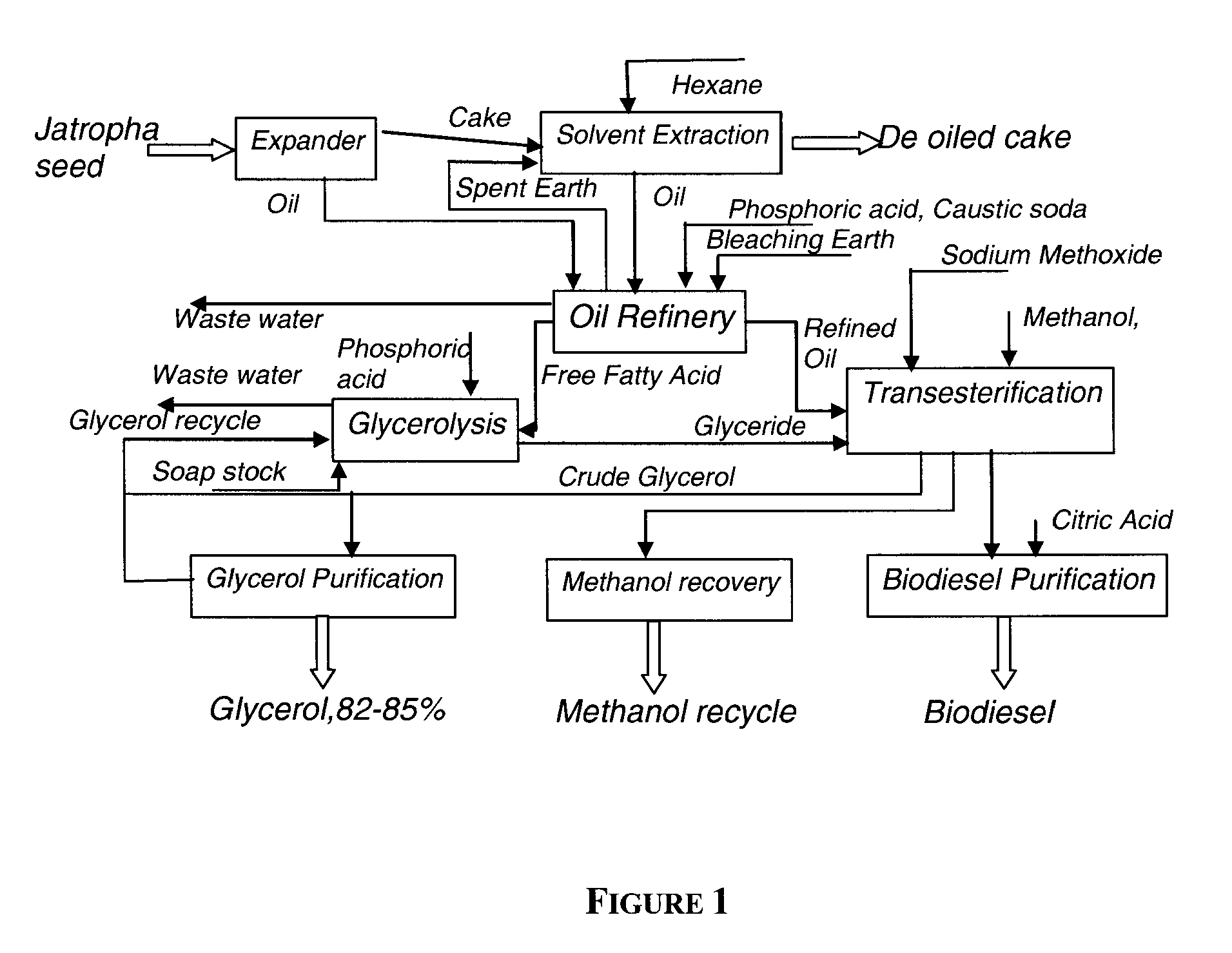

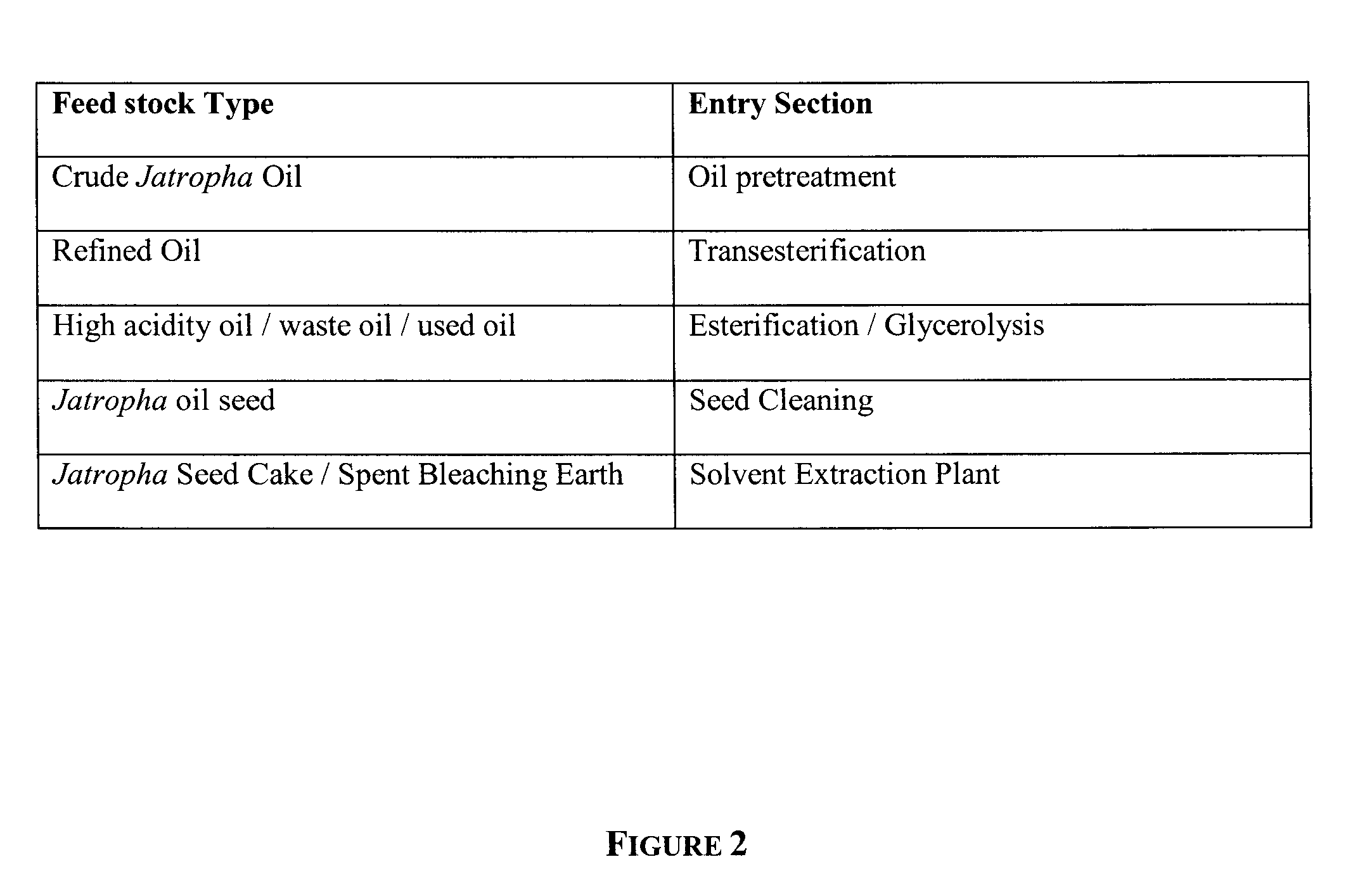

Integrated Process for the Preparation of Fatty Acid Methyl Ester (Biodiesel)

InactiveUS20080269513A1Fatty oils/acids recovery from wasteFatty acid esterificationVegetable oilGlycerol ester of wood rosin

The disclosure provides methods and systems for the production of biodiesel from biological feedstocks such as vegetable oils or animal fats. In particular, the disclosure is directed to the product of biodiesel from seeds such as non-edible oil seeds. Methods for maximizing oil recovery from the feedstocks are provided, as well as methods to convert free fatty acids in the feedstocks into glycerides amenable to transesterification. Thus the methods and systems provide for efficient biodiesel production.

Owner:RELIANCE LIFE SCI PVT

Lubricant base from palm oil and its by-products

The invention relates to a biodegradable functional fluid composition based on vegetable oil. This functional fluid suitable for lubricant, hydraulic and like fluid comprises palm olein and its by-product generated from fractionation of palm oil. The by-product is esterified by a hindered alcohol prior to blend together with palm olein and additive packages. The hydraulic fluid particularly suited for tropical climate with temperature ranging from 15-40° C.

Owner:MALASIAN PALM OIL BOARD

Method for producing fats or oils

ActiveUS7452702B2Fatty oils/acids recovery from wasteFatty acid esterificationTransesterificationEnzyme

The present invention is directed to improving productivity of an enzymatic method for making esterified, transesterified or interesterified products. Specifically, a method that can greatly improve the productivity of enzymatic transesterification or esterification by deodorization alone, or by deodorization and purification of the initial substrate to extend the useful life of the enzyme is disclosed.

Owner:ARCHER DANIELS MIDLAND CO

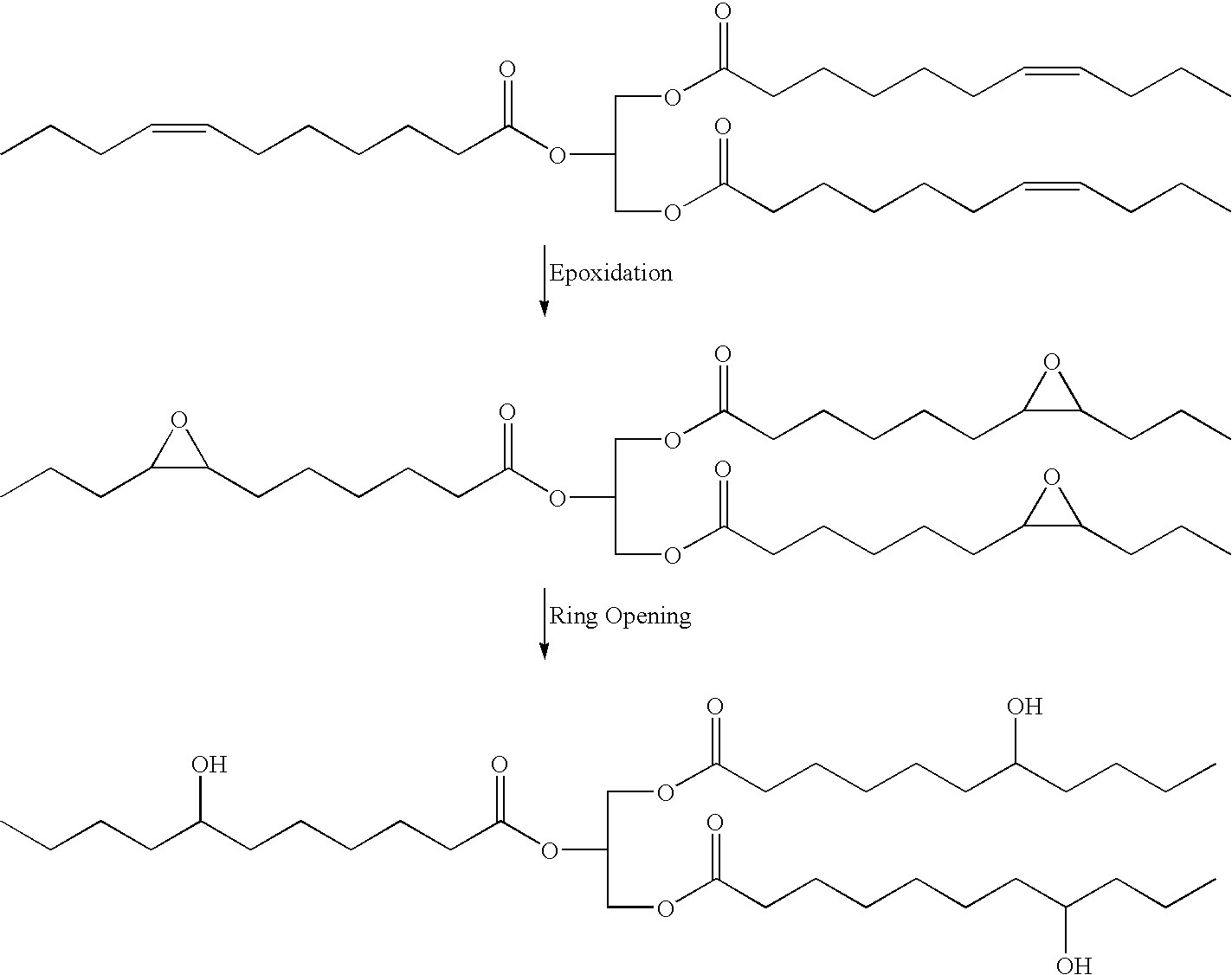

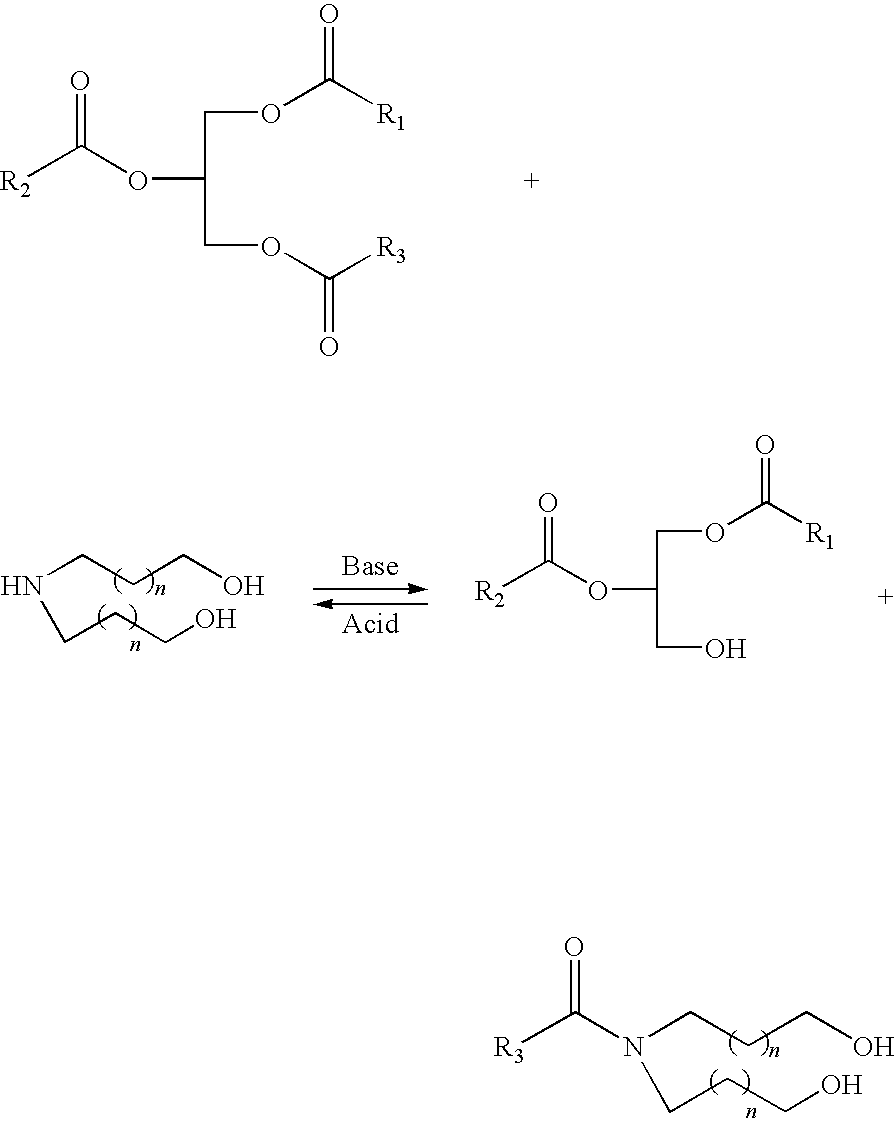

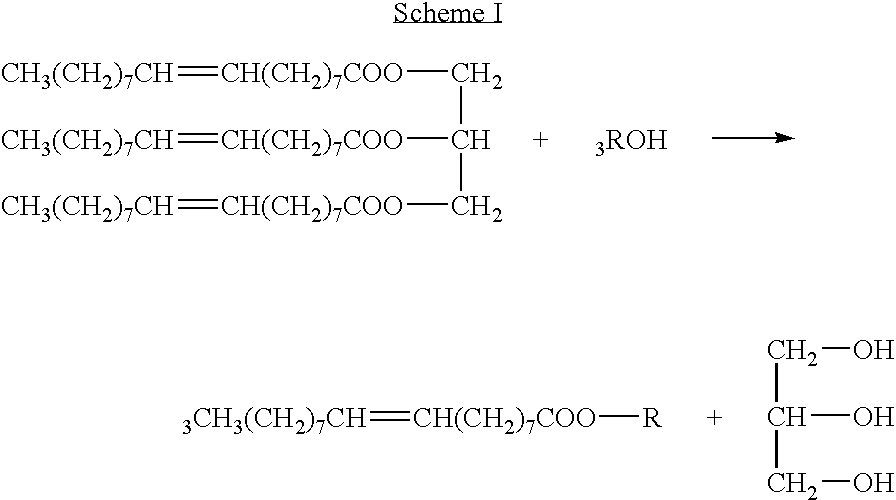

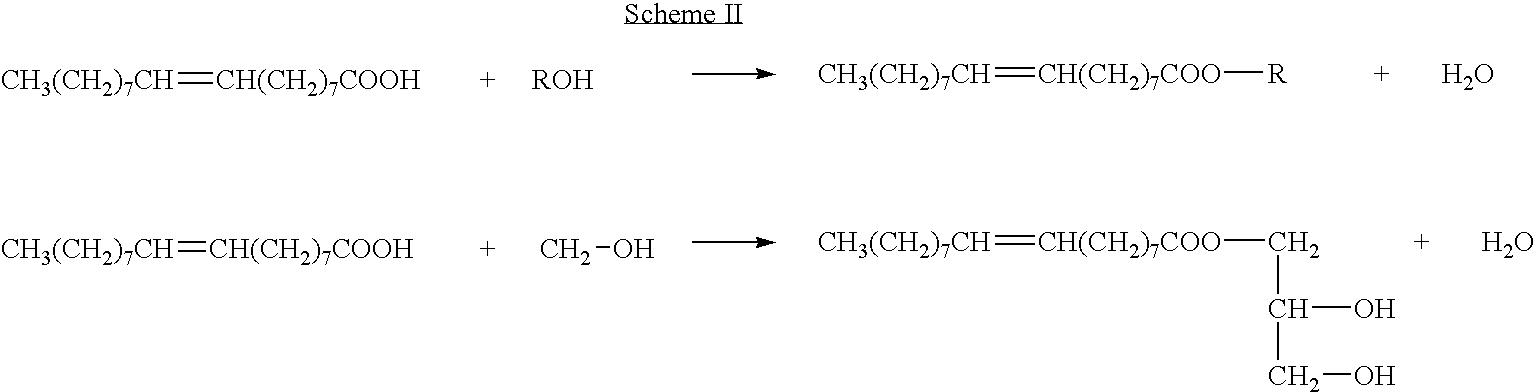

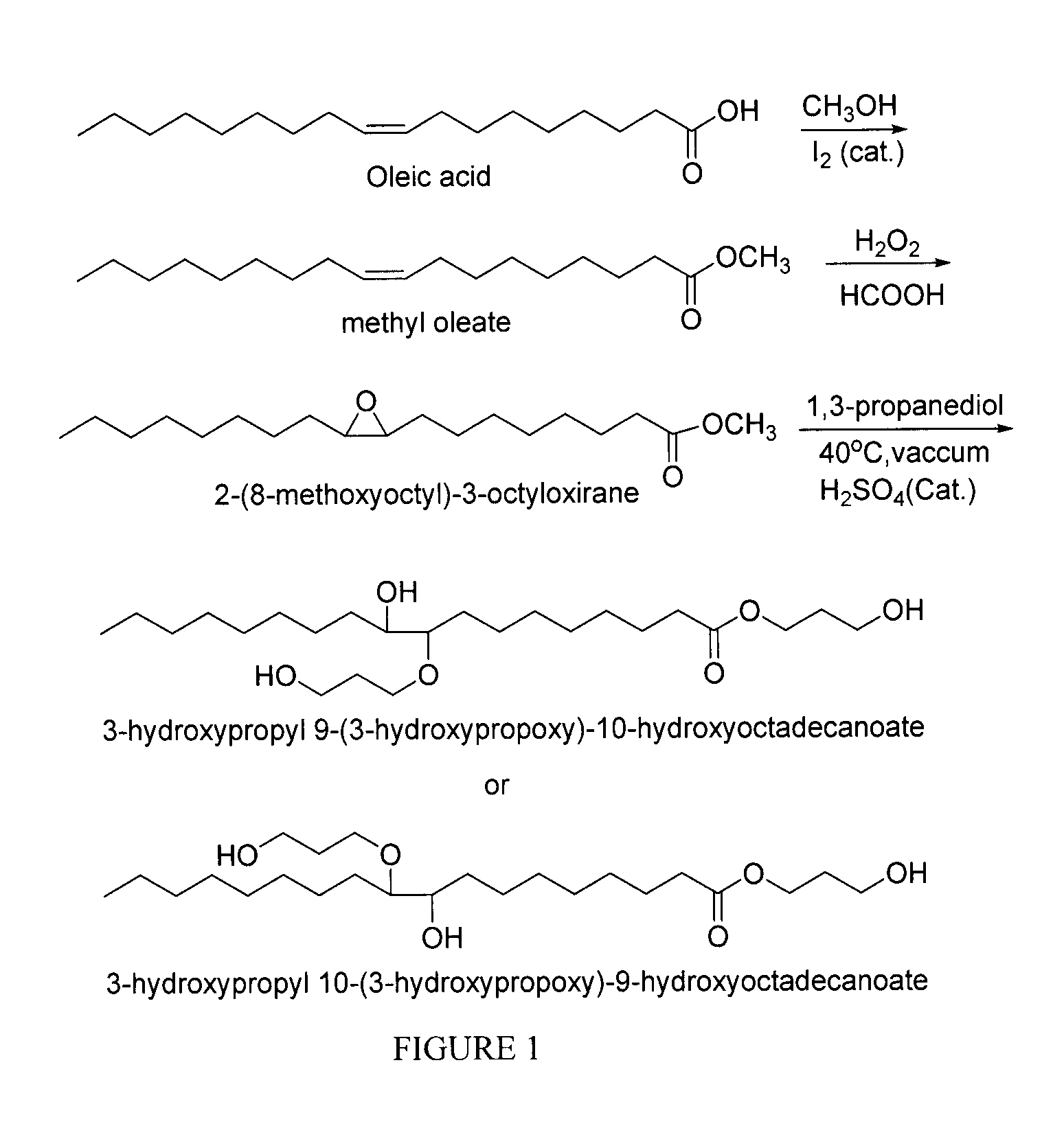

Polyols from plant oils and methods of conversion

ActiveUS7674925B2Avoiding challengeAvoid problemsOrganic compound preparationCarboxylic acid esters preparationPolyolHydrogen

Methods of producing plant polyols from plant oils include reacting a plant oil with a designed reactant having one or more nucleophilic functional groups and one or more active hydrogen functional groups in the presence of an addition reaction catalyst in a single reaction step. The resultant polyols may be directly reacted with polyisocyanates to produce polyurethanes.

Owner:MCPU POLYMER ENG

Process for transesterification of vegetable or animal oils using heterogeneous catalysts based on titanium, zirconium or antimony and aluminium

InactiveUS7592470B2Fatty acid esterificationFatty acids production/refiningTitanium oxideHomogeneous catalysis

A novel process is described for producing esters of linear monocarboxylic acids containing 6 to 26 carbon atoms, by reacting vegetable or animal oils, neutral or otherwise, with monoalcohols containing 1 to 18 carbon atoms in the presence of a catalyst selected from:mixtures of titanium oxide and alumina having formula:(TiOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y, representing the weight ratio of the two oxides, has a value of 0.005 to 0.995;mixtures of zirconium oxide and alumina having formula:(ZrOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y has a value of 0.005 to 0.995;and mixtures of antimony oxide and alumina having formula:(SbOx)y(Al2O3)1-y where x has the value 1.2 to 2.6 and y has a value of 0.005 to 0.995, in order to directly produce, in one or more steps, an ester for use as a fuel and a pure glycerin.

Owner:INST FR DU PETROLE

Poly(hydroxy thioether) vegetable oil derivatives useful as lubricant additives

InactiveUS7279448B2Expand the marketReduce demandOrganic compound preparationSurface-active detergent compositionsPolymer scienceVegetable oil

A novel class of chemically-modified vegetable oils is prepared by reacting epoxidized triglyceride oils with thiols. The resultant poly(hydroxy thioether) derivatives have utility as antiwear / antifriction additives for environmentally-friendly industrial oils and automotive applications.

Owner:US SEC AGRI +1

Apparatus and method for producing biodiesel from fatty acid feedstock

A method comprising applying a controlled flow cavitation apparatus to a biodiesel production process in order to increase fatty acid alkyl ester yield. A feedstock comprising free fatty acids can be passed through a controlled flow cavitation apparatus at a velocity capable of generating a hydrodynamic cavitation zone where the free fatty acids can be esterified. One or more controlled flow cavitation apparatuses can be applied at various points of a biodiesel production process.

Owner:ARISDYNE STSTEMS INC

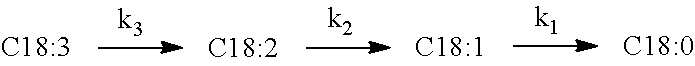

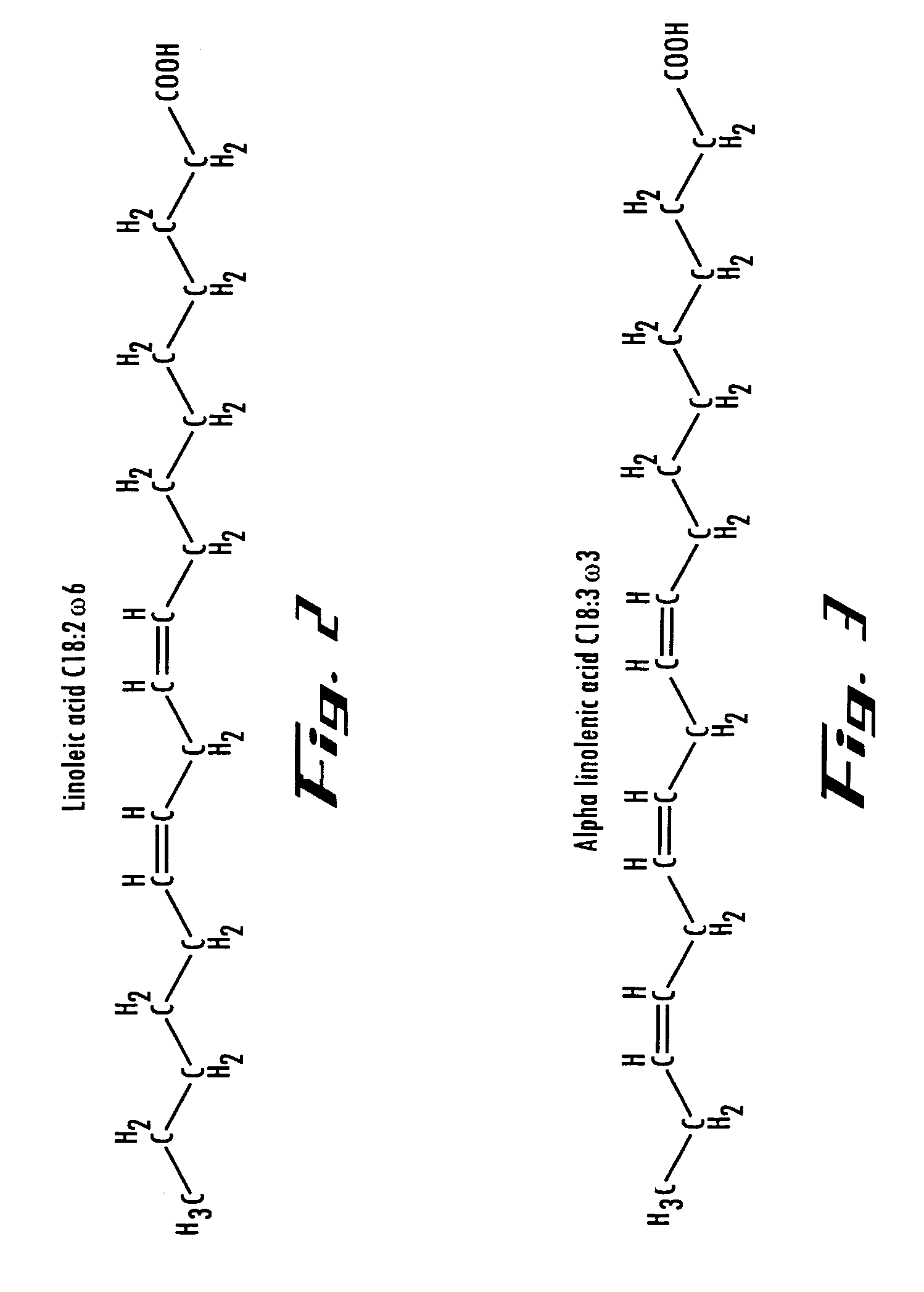

Edible fat and oil, process of producing the same, and chocolate containing fat and oil composition

InactiveUS20100112161A1Improve blooming resistanceFatty acid esterificationDrying-oilsChemical compositionEsterification reaction

[Purpose] To provide edible fat and oil that can further improve blooming resistance, and chocolate having further improved blooming resistance than that of conventional chocolate. [Constitution] Edible fat and oil obtained by transesterification reaction or esterification reaction and satisfying the following requirements (A) to (D): (A) iodine value: 15 to 29; B) amount of trans fatty acids in the constituent fatty acids: 16 to 29% by mass; (C) amount of lauric acid in the constituent fatty acids: 13 to 28% by mass; and (D) total amount of oleic acid, linoleic acid, and linolenic acid in the constituent fatty acids: less than 10% by mass.

Owner:THE NISSHIN OILLIO GRP LTD

Glyceride oil composition from fish oil and preparation method thereof

ActiveUS20100062107A1Reduce disadvantagesPromote digestionFatty oils/acids recovery from wasteFatty acid esterificationWater dispersibleFish oil

Provided are a glyceride oil composition derived from a fish oil and a preparation method thereof. The composition includes docosahexaenoic acid (DHA) and docosapentaenoic acid (DPA) with a content of 45 to 95% by weight and eicosapentaenoic acid (EPA) with a content of 0.001 to 13% by weight among constituent fatty acids, and a saturated fatty acid having 16 to 18 carbon atoms, which is bonded at 1- and 3-positions, with a content of 0.001 to 5% by weight among constituent fatty acids, in which a weight ratio of docosahexaenoic acid (DHA) / docosapentaenoic acid (DPA) is 0.5 to 8 and a weight ratio of docosahexaenoic acid (DHA) / eicosapentaenoic acid (EPA) is 3.5 to 15. The glyceride oil composition derived from fish oil has nutritional and physiological superiority due to containing a great amount of polyunsaturated fatty acids such as DHA and DPA in a form of glyceride, and can minimize disadvantages of EPA such as inhibition of ω-6 fatty acid metabolism by containing a low amount of EPA. The glyceride oil composition is excellent in digestion and absorption of polyunsaturated fatty acids into a human body by containing a low amount of saturated fatty acids at 1- and 3-positions and process characteristics such as an oxidation stability and water-dispersibility.

Owner:ILSHINWELLS

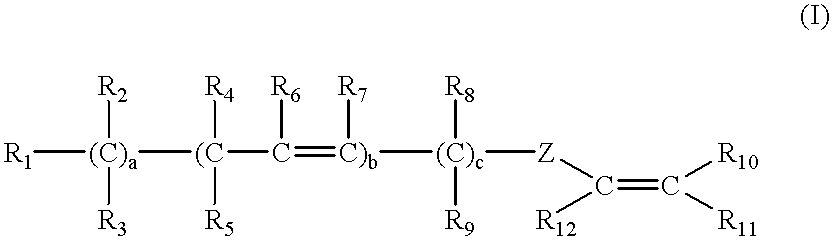

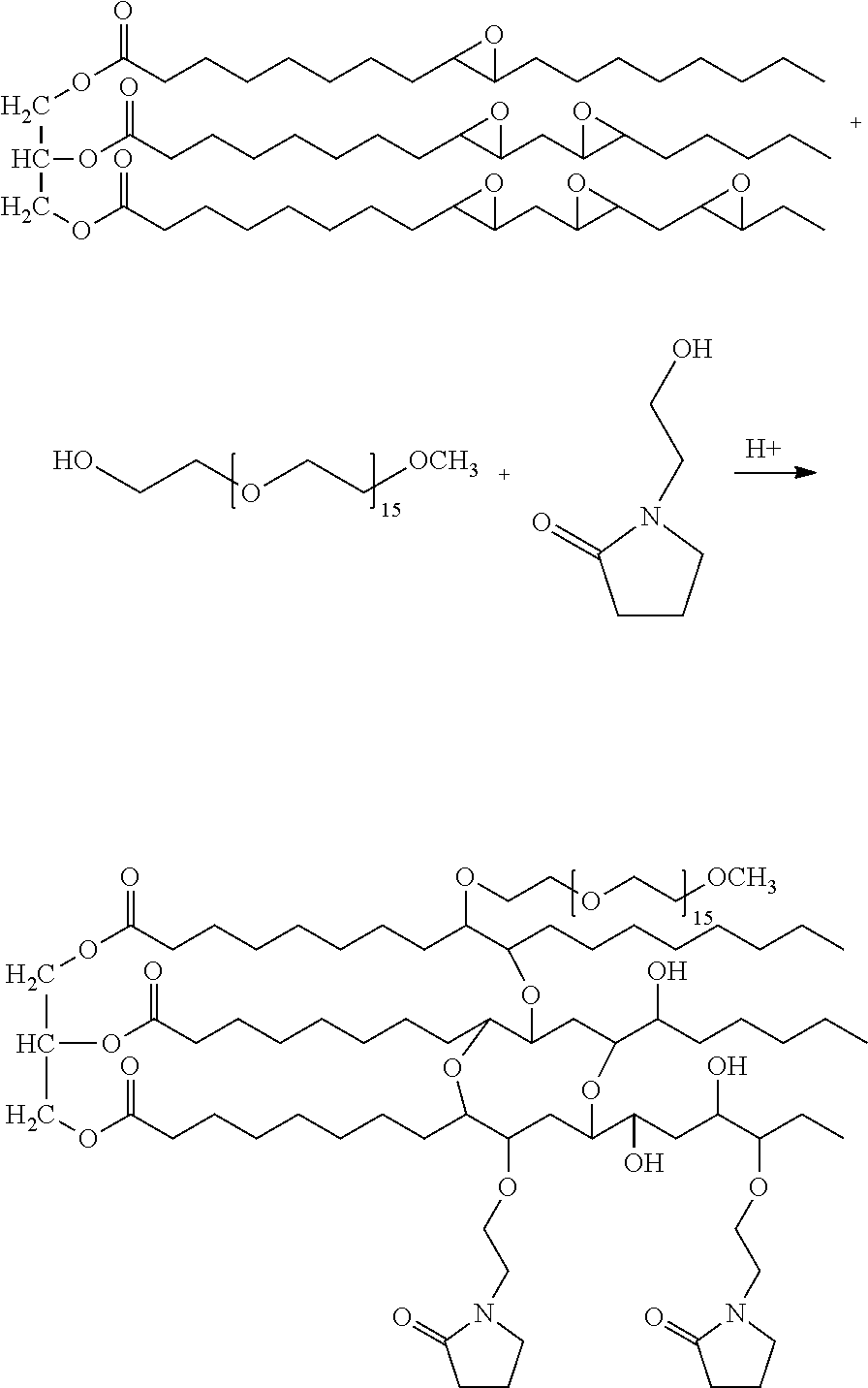

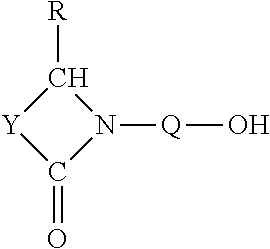

Renewable modified natural compounds

Provided are modified natural compounds that are produced, at least in part, from (A) at least one epoxidized and / or maleated natural fatty acid, or epoxidized and / or maleated natural oil, and (B) at least one lactam having at least one hydroxyl functional group, wherein the lactam may be in a blend with one or more optional alcohol(s). Among other properties, the modified natural compounds may exhibit dispersibility or solubility characteristics in water and / or alcohols. The invention further provides a wide variety of compositions comprising the modified natural compounds.

Owner:ISP INVESTMENTS LLC

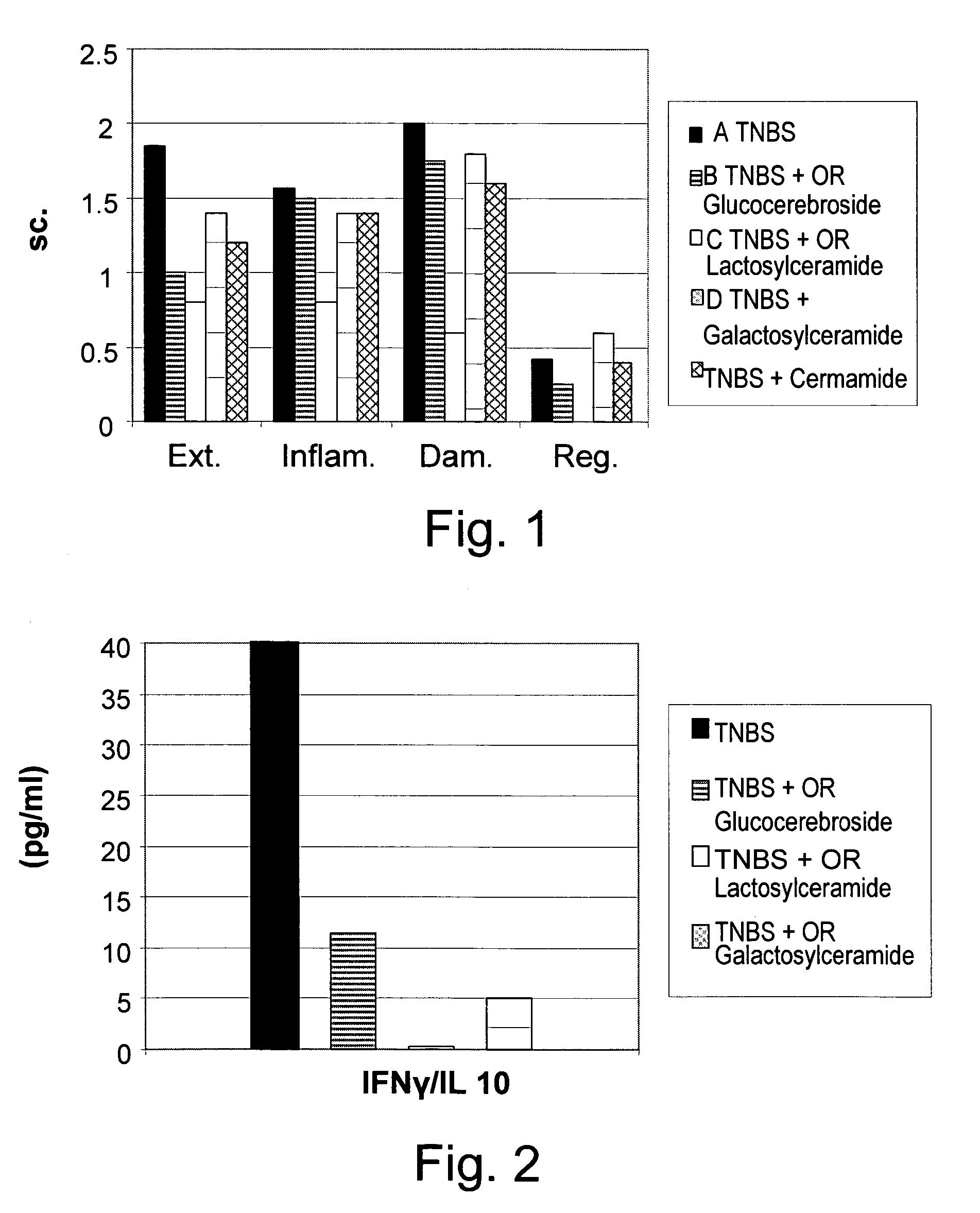

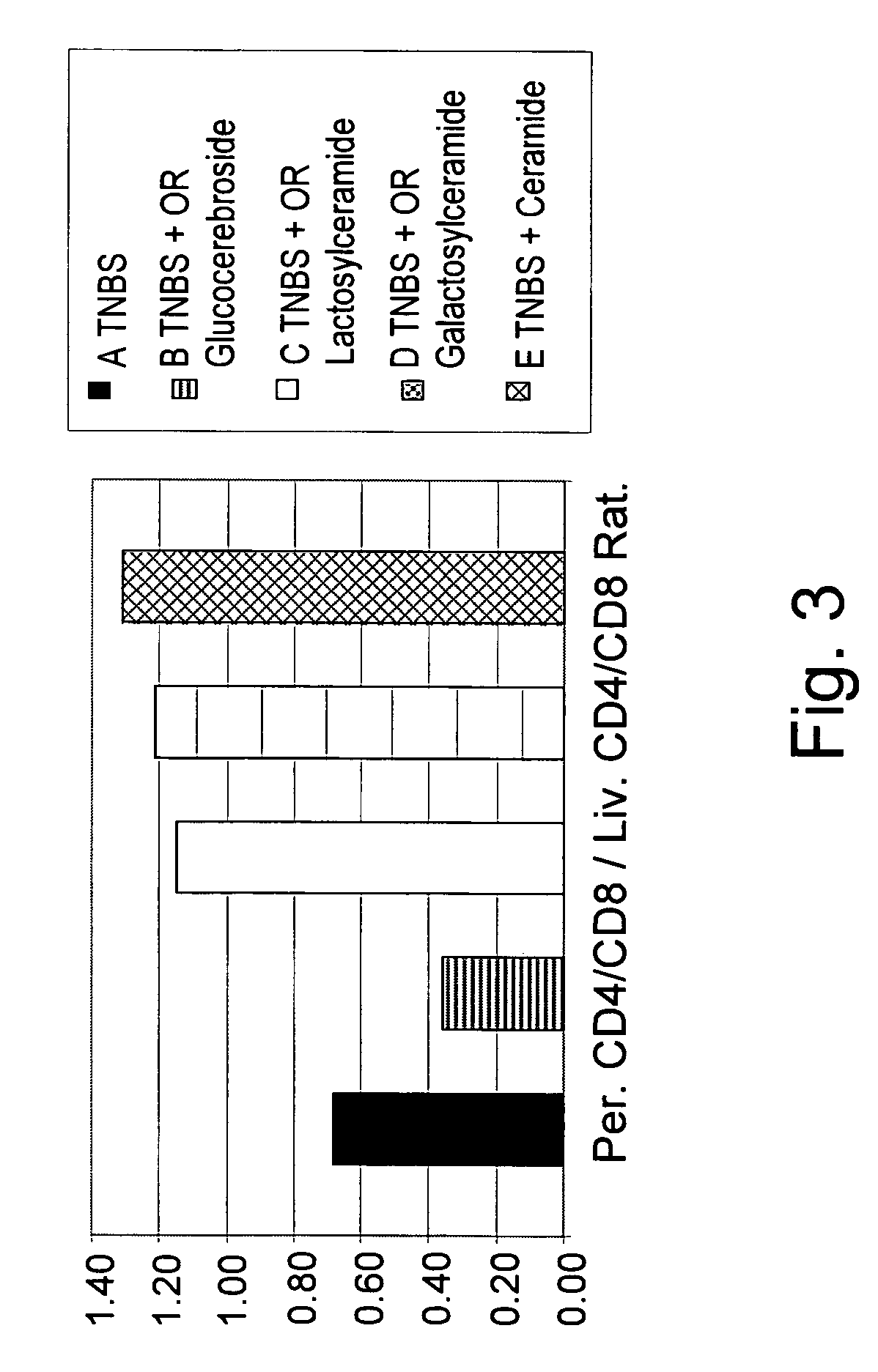

Β glycolipids as immuno-modulators

The invention relates to the use of β-glycolipids as immunomodulators. More particularly, the invention relates to the use of β-glycolipids, preferably, β-lactosyl-ceramide, β-glucosylceramide, β-galactosyl-ceramide, ceramid and β-lactosyl-ceramide, as well as any mixture or combination thereof for the treatment of immune related disorders. The present invention further relates to a process for the modulation of the Th1 / Th2 cell balance toward anti-inflammatory cytokine producing cells, in a subject suffering from an immune related disorder. Therapeutic compositions and method for the preparation of these compositions are also provided.

Owner:ENZO THERAPEUTICS ENZO BIOCHEM

Low SAFA oils

InactiveUS6040161ADifferent melting pointDifferent solubilityFatty acid esterificationHydrolasesSolubilityTriglyceride

Liquid oils with a SAFA-content of less than 5 wt % can be obtained by conversion of a fatty compound (A), preferably having a SAFA-level of more then 5 wt %, with a reactant (B), capable of forming different reaction products of the non-triglyceride type (C1, C2 etc.) having a different melting point and / or different solubility in compound (A); the SAFA-level of the end product can be controlled by separating the precipitate of the higher melting more saturated reaction-products (C1, C2 etc.) from the rest of the reaction mixture.

Owner:LODERS CROKLAAN

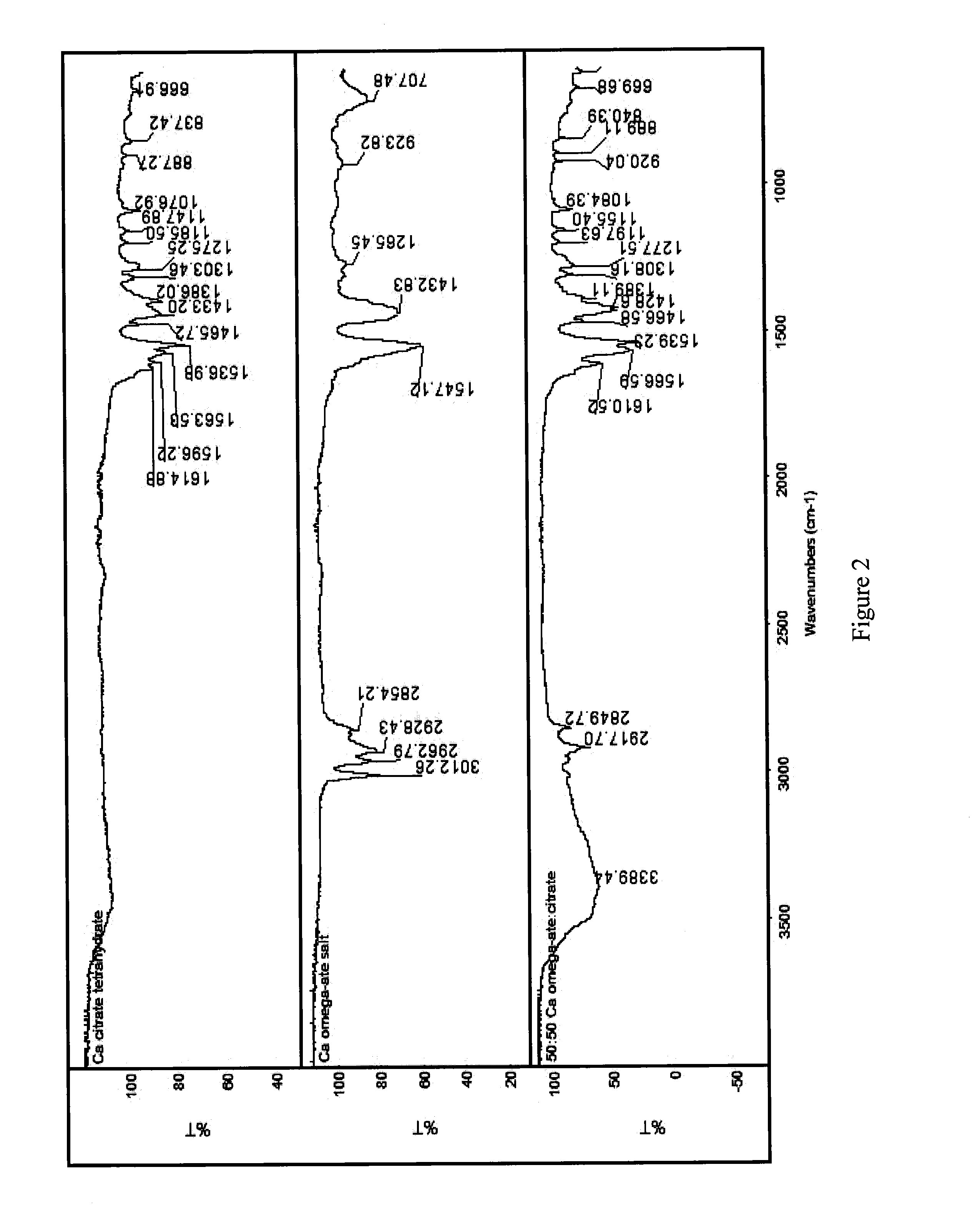

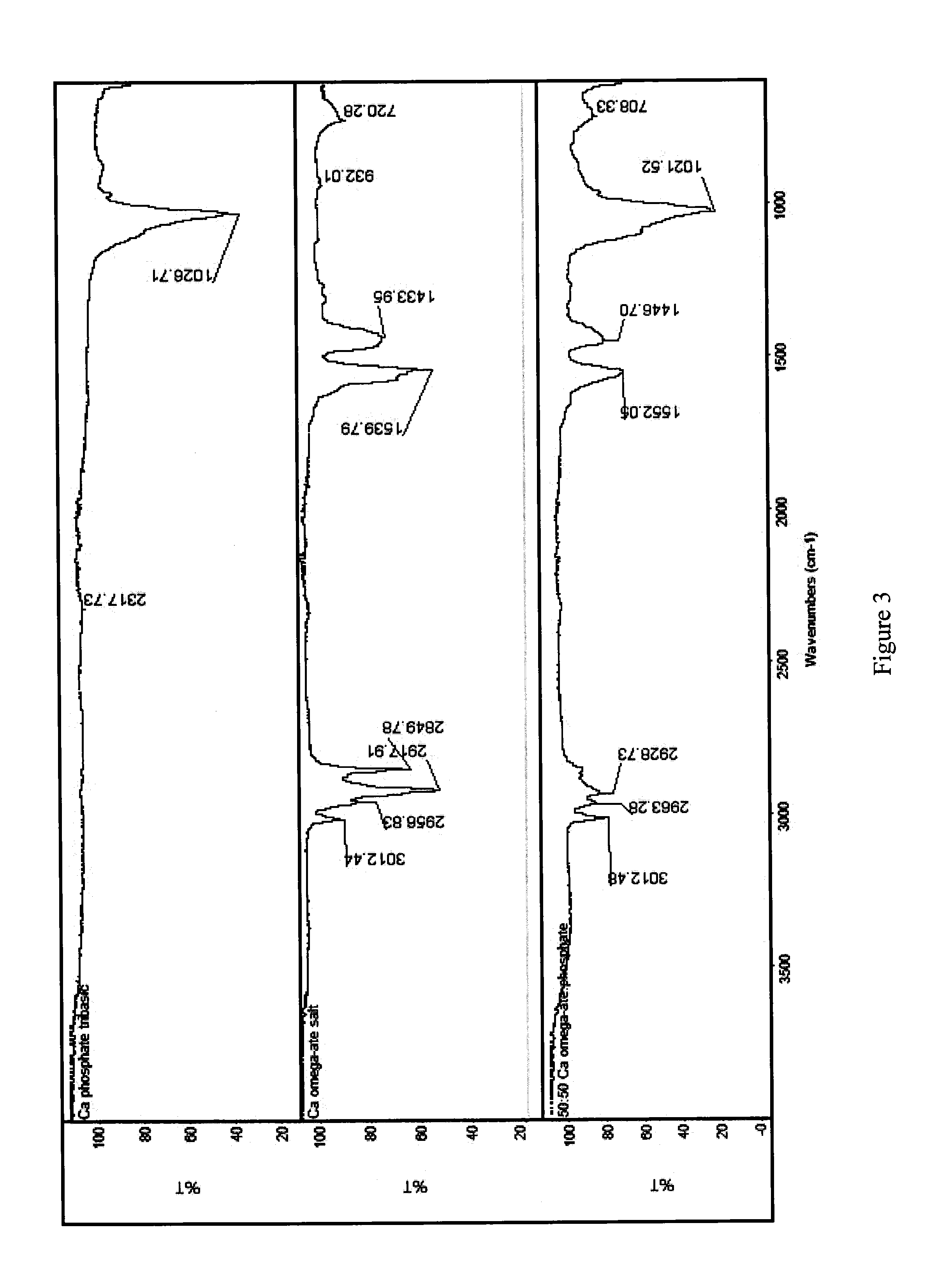

Co-precipitated salts of fatty acids

ActiveUS20120116106A1Fatty acid chemical modificationMetabolism disorderIodo fatty acidDietary supplement

A co-salt of a polyunsaturated fatty acid and a non-fatty acid is formed as a precipitate. The co-salt formed is free flowing and does not tend to agglomerate (cake) in storage. The resultant co-salt product will be easy to blend with other products to produce dietary supplements. These novel co-salt products may also tablet very well and may be added to current dietary supplement tablets.

Owner:JOST CHEM

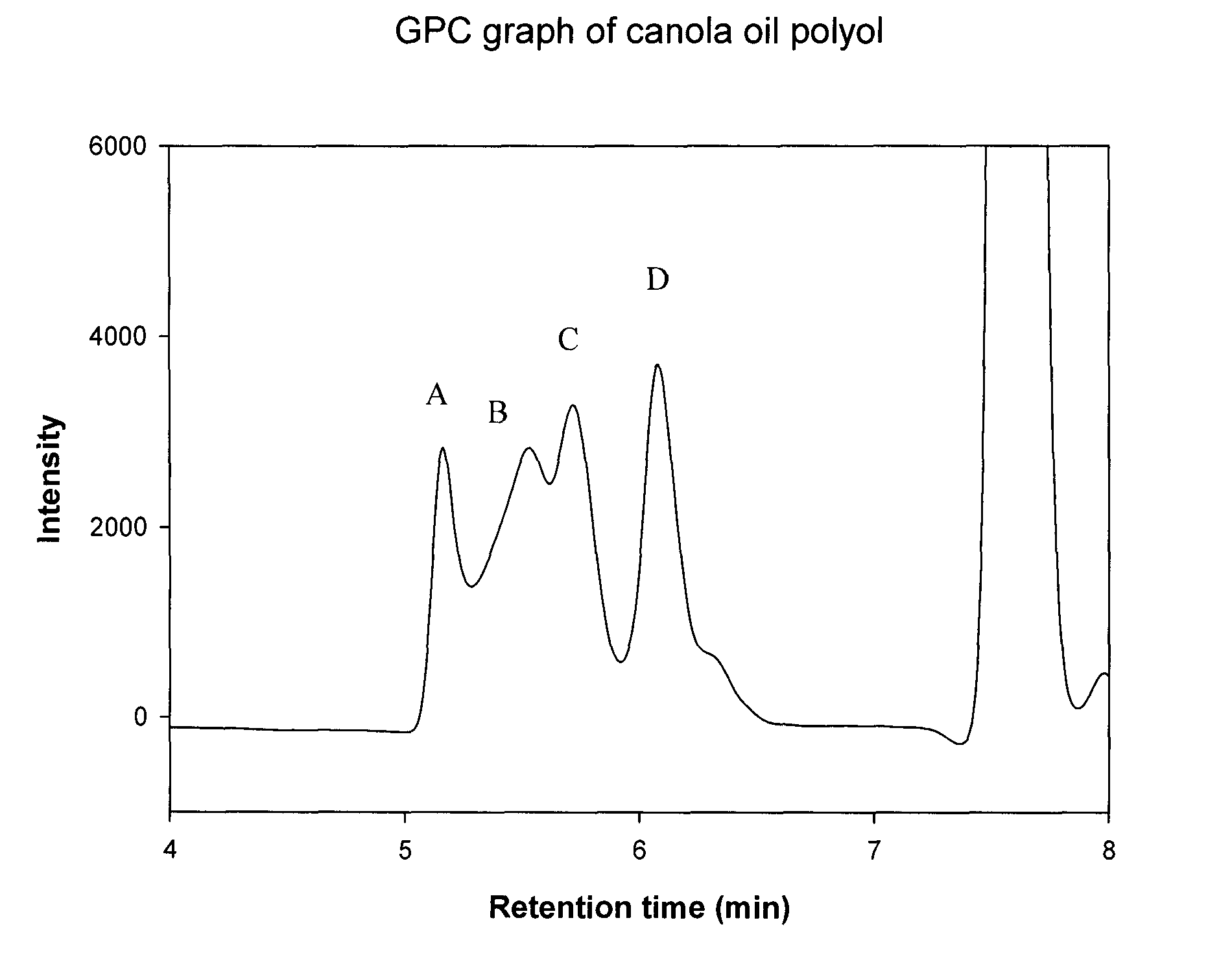

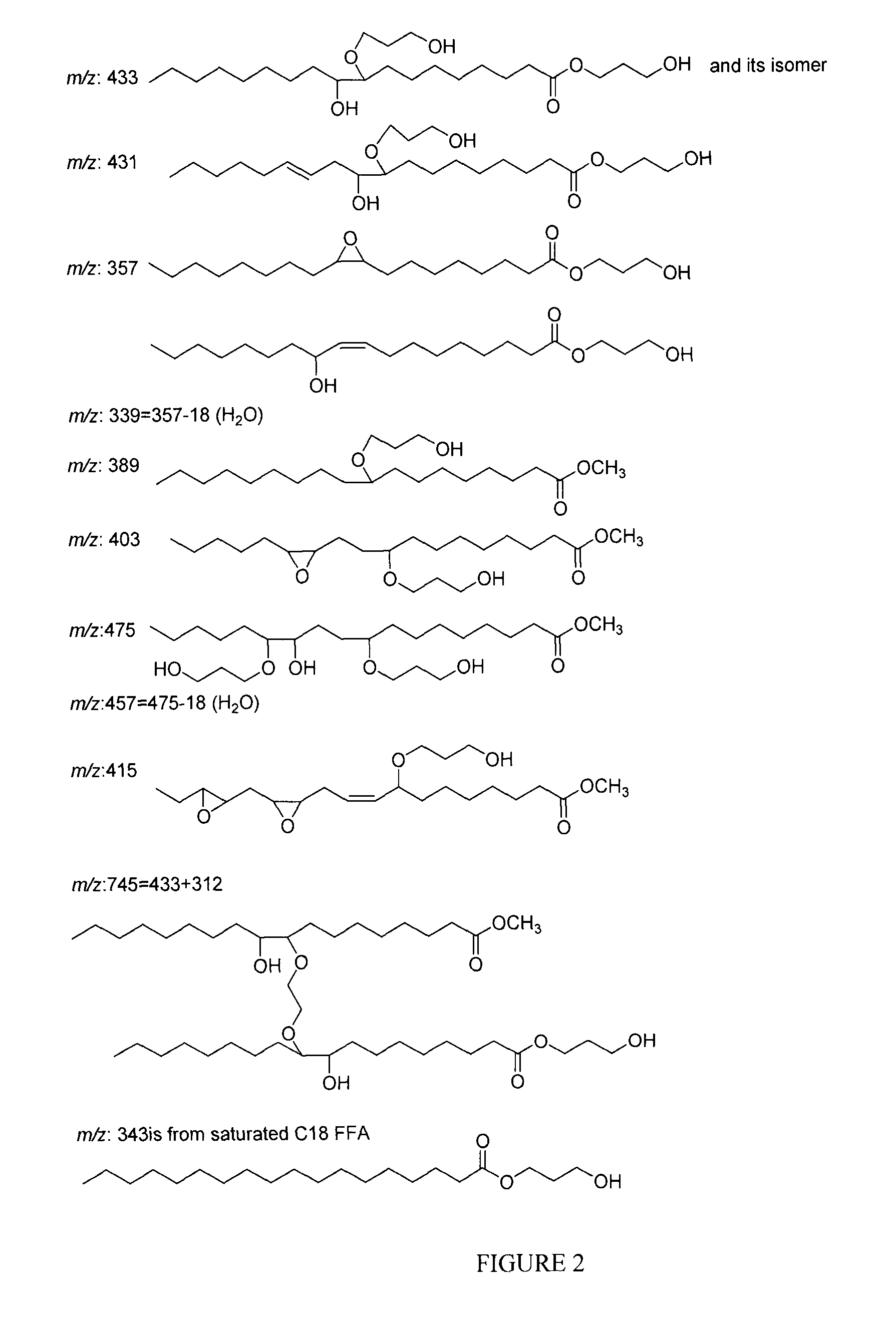

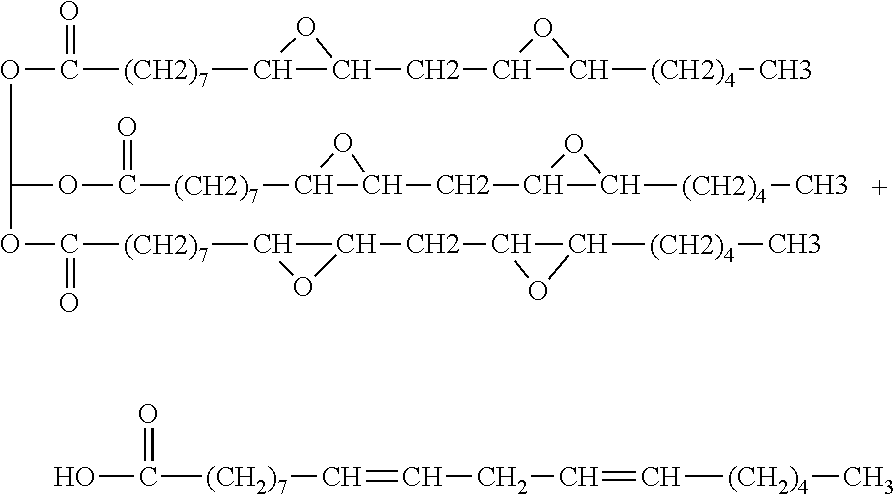

Polyol synthesis from fatty acids and oils

ActiveUS9216940B2Low viscosityReduce molecular weightFatty acid esterificationFatty acids production/refiningIodo fatty acidPolyol synthesis

A method for preparing polyols from fatty acid substrates such as free fatty acids, alkyl esters of fatty acids, mono-glycerides, diglycerides, and triglycerides. The method comprises the steps of (a) epoxidizing an unsaturated fatty acid substrate and (b) hydroxylating the epoxidized fatty acid substrate with at least one diol to produce a polyol or a blend of polyols. The method may be varied to produce polyols with desired functionality, molecular weights, or viscosity.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

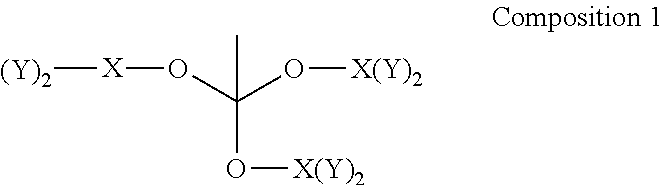

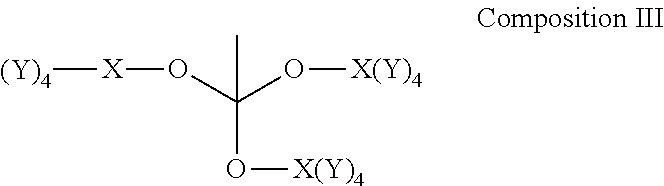

Natural based branched compositions

InactiveUS20140031570A1Efficient curingImprove curing speedOrganic chemistrySynthetic resin layered productsPolymer scienceDendritic branch

A linoleum composition including a dendritic substituent comprising a polyfunctional core including a plurality of primary branches extending; from the core and (ii) a plurality of dendritic branches extending from the plurality of primary branches, and each dendritic branch having an unsaturated functionality.

Owner:AFI LICENSING

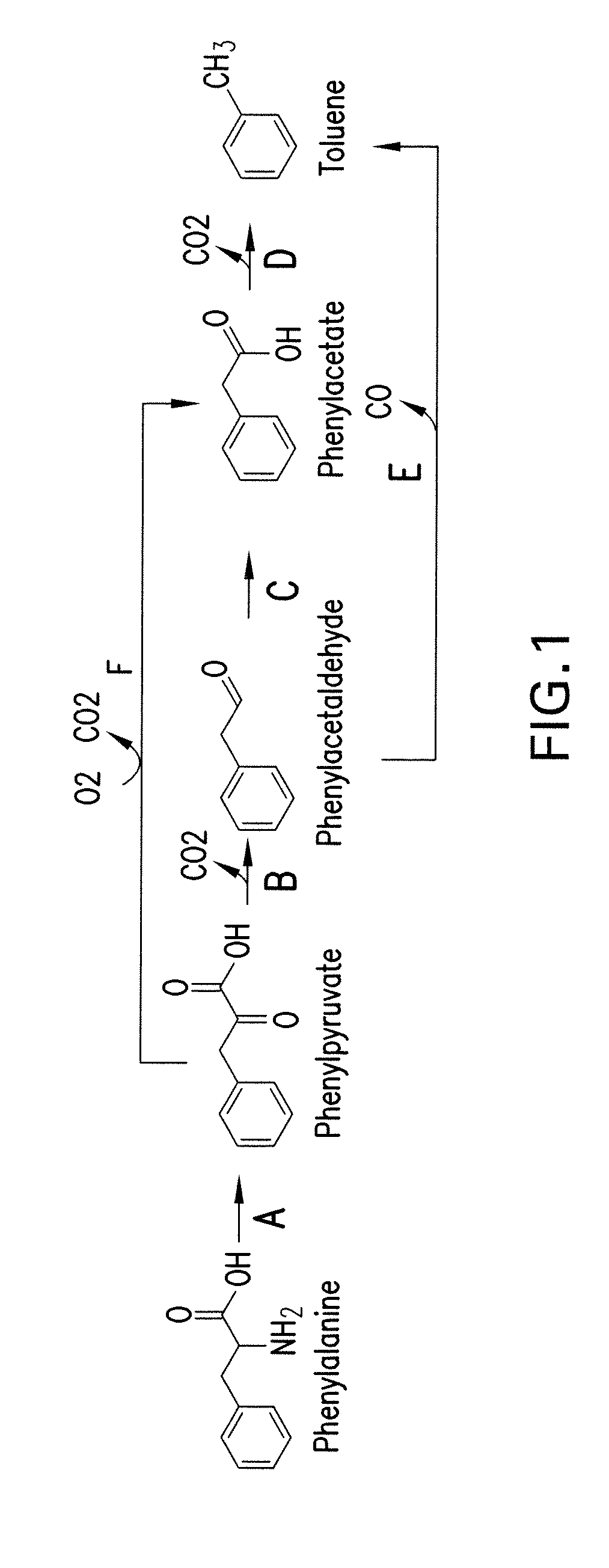

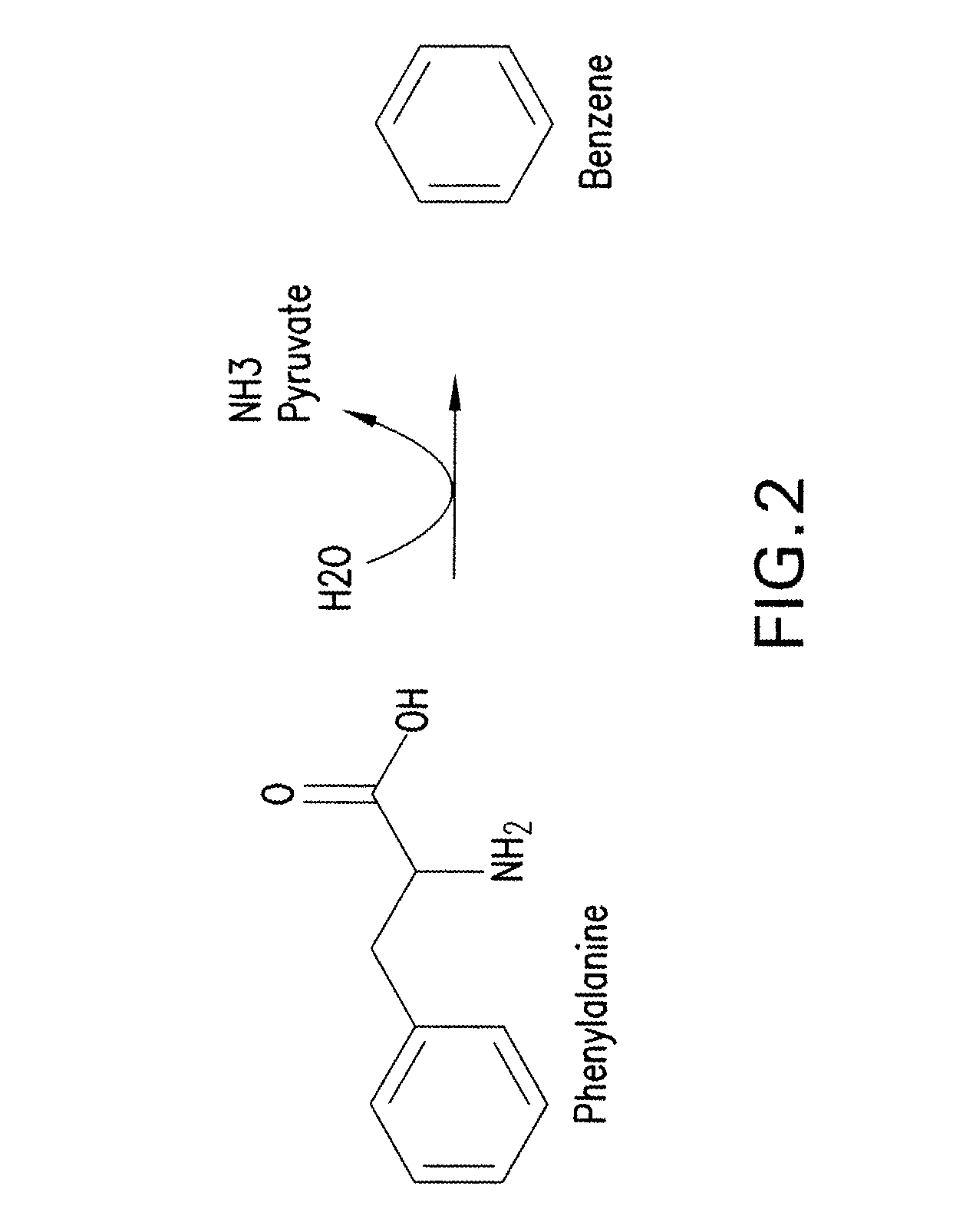

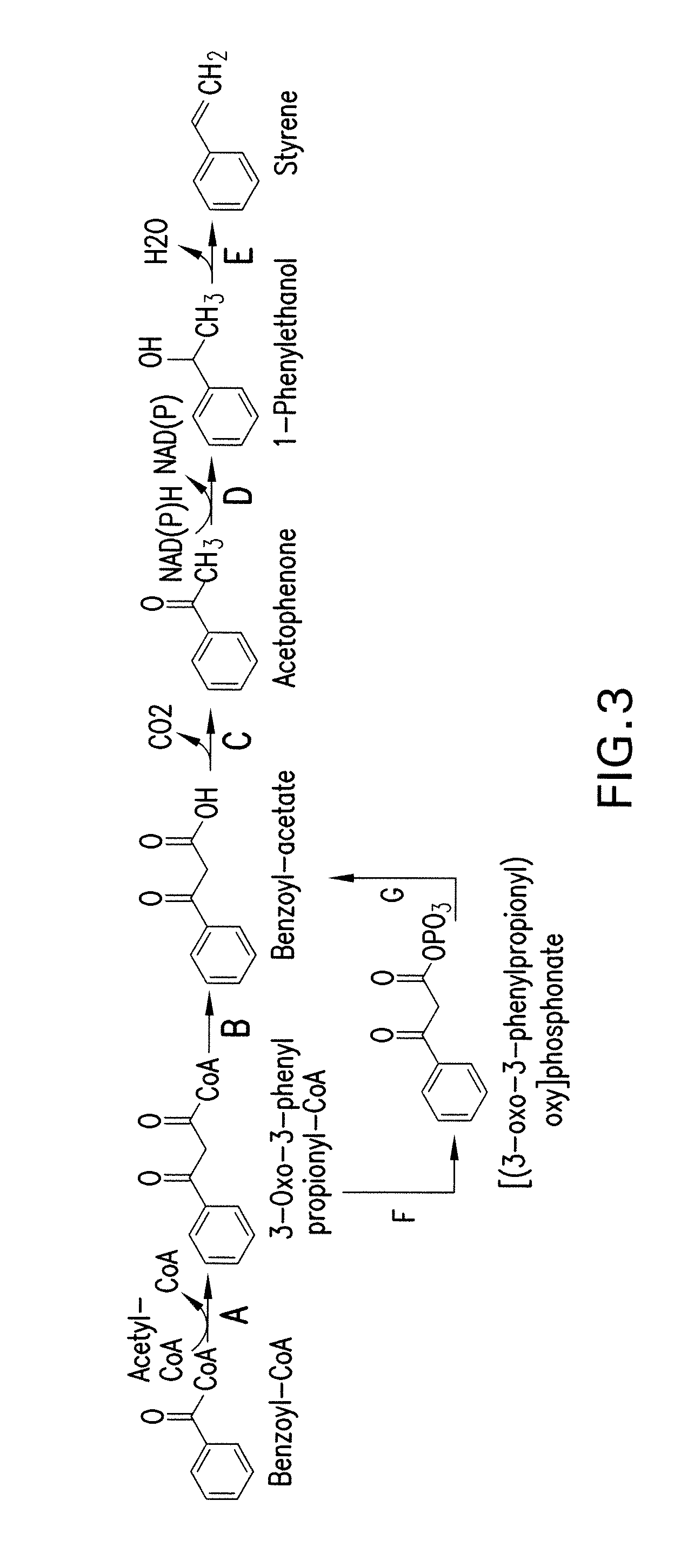

Microorganisms and methods for the biosynthesis of aromatics, 2,4-pentadienoate and 1,3-butadiene

Owner:GENOMATICA INC

Process for obtaining fatty acid alkyl esters, rosin acids and sterols from crude tall oil

ActiveUS20060235198A1Fatty oils/acids recovery from wasteFatty acid esterificationAlcoholSterol ester

The disclosed invention refers to a process for obtaining fatty acid alkyl esters, rosin acids and sterols from crude tall oil (CTO), which is characterised by the following steps: (a) reacting the free fatty acids present in the CTO with lower alcohols; (b) esterifying the sterols in the CTO with boric acid or transesterifying the sterols with a catalyst; (c) separating the fatty acid lower alkyl esters and rosin acids from the remaining sterol borate esters or sterol esters of fatty acids to produce a stream of sterol esters; (d) separating the fatty acid alkyl esters from the rosin acids to produce a first stream of fatty acid alky esters and a second stream of rosin acids; and (e) converting the sterol esters into the free sterols to produce a third stream of free sterols.

Owner:COGNIS IP MANAGEMENT GMBH

Methods for Concentration and Extraction of Lubricity Compounds and Biologically Active Fractions From Naturally Derived Fats, Oils and Greases

InactiveUS20090320353A1Speed up the extraction processImprove concentrationFatty acid esterificationDrying-oilsOil and greaseDistillation

Owner:AGRI & AGRI FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com