Modified geopolymer bonding agent and application method for rapidly renovating old ceramic tile wall surface thereof

A technology of geopolymers and interface agents, applied in the direction of coating, etc., can solve the problems of poor durability, poor aging resistance, high cost, etc., and achieve good shear bond strength, good tensile bond strength, and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

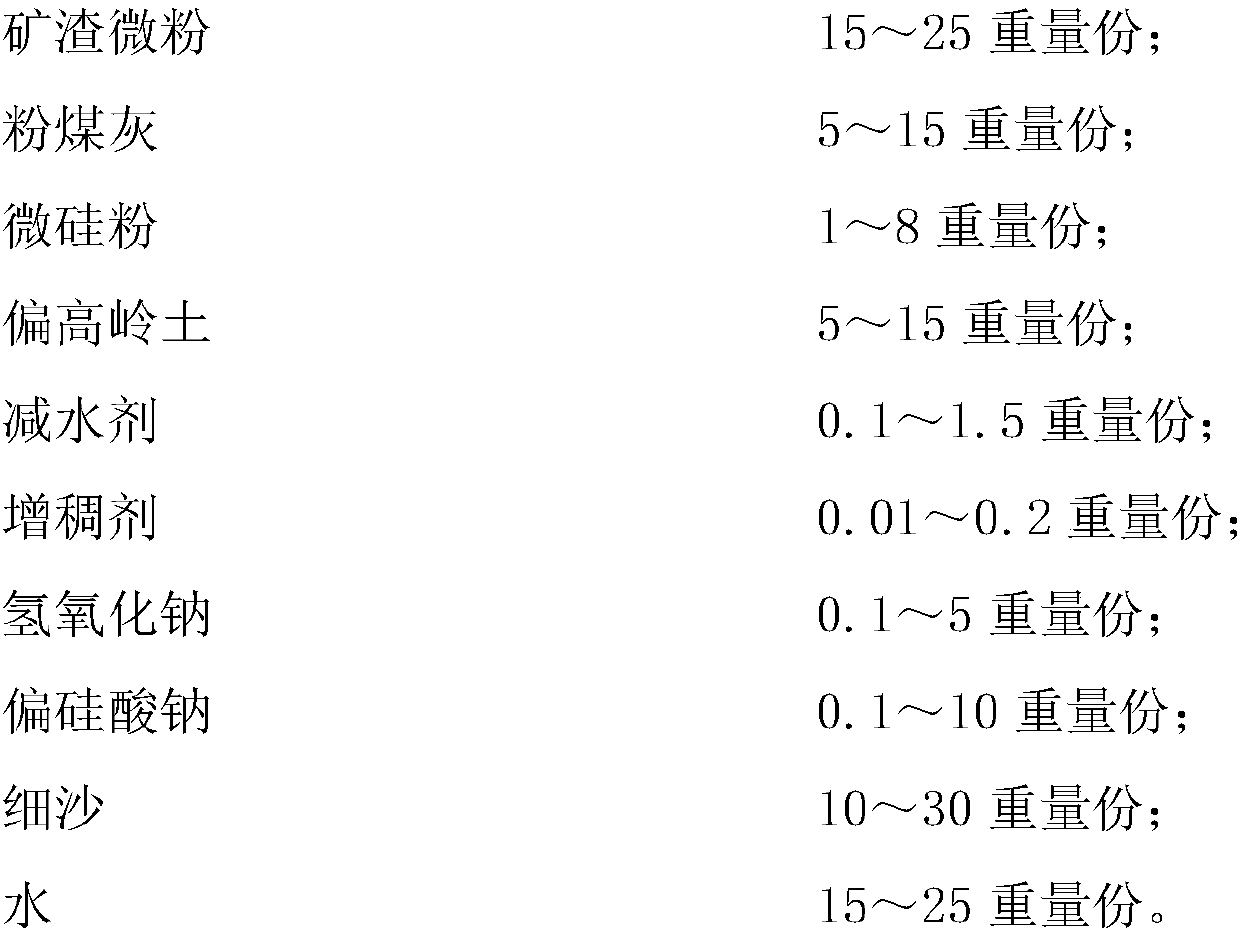

[0042] The weight ratio of each component of the modified geopolymer interface agent for the rapid renovation of the old tile wall of the present invention is:

[0043] 80 parts by weight of geopolymer slurry;

[0044] 20 parts by weight of emulsion feed liquid;

[0045] The geopolymer feed liquid components include:

[0046]

[0047]

[0048] The ratio of parts by weight of the emulsion feed liquid is:

[0049] 15 parts by weight of styrene-acrylic emulsion;

[0050] Sodium water glass 4.95 parts by weight

[0051] 0.05 parts by weight of antifungal agent;

Embodiment 2

[0053] The weight ratio of each component of the modified geopolymer interface agent for the rapid renovation of the old tile wall of the present invention is:

[0054] 70 parts by weight of geopolymer slurry;

[0055] 30 parts by weight of emulsion feed liquid;

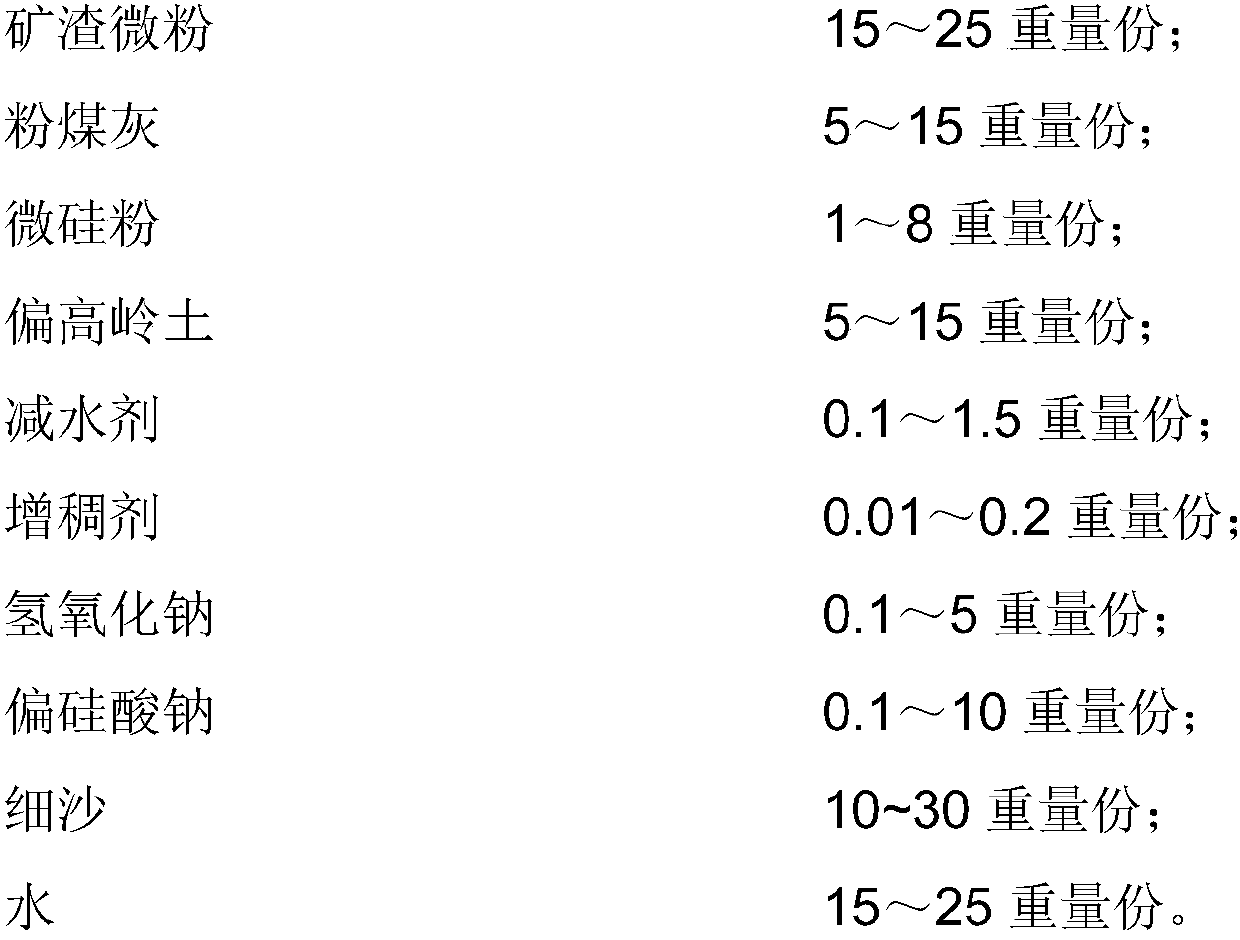

[0056] The geopolymer feed liquid components include:

[0057]

[0058] The ratio of parts by weight of the emulsion feed liquid is:

[0059] 20 parts by weight of styrene-butadiene emulsion;

[0060] Soda water glass 9.9 parts by weight

[0061] 0.1 parts by weight of antifungal agent;

Embodiment 3

[0063] The weight ratio of each component of the modified geopolymer interface agent for the rapid renovation of the old tile wall of the present invention is:

[0064] 75 parts by weight of geopolymer slurry;

[0065] 25 parts by weight of emulsion feed liquid;

[0066]The geopolymer feed liquid components include:

[0067]

[0068] The weight ratio of described emulsion feed liquid is:

[0069] 15 parts by weight of pure acrylic emulsion;

[0070] Soda water glass 9.9 parts by weight

[0071] 0.1 parts by weight of antifungal agent;

[0072] A modified geopolymer interface agent prepared in the above-mentioned embodiments of the present invention has higher bonding strength and better acid and alkali corrosion resistance compared with the existing common interface agent, and can be used in various harsh weather environments Both can have extremely strong durability.

[0073] With reference to the test method of JC / T 907-2002 "Concrete Interface Treatment Agent", the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com