Amphiphilic polymer oil-displacing agent with biquaternary ammonium salt long chain structure and preparation method of amphiphilic polymer oil-displacing agent

A technology of amphiphilic polymer and biquaternary ammonium salt, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of small branching degree and low charge density of polymer molecules, and achieves large branching degree. , The effect of good hydrophobic site and good apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

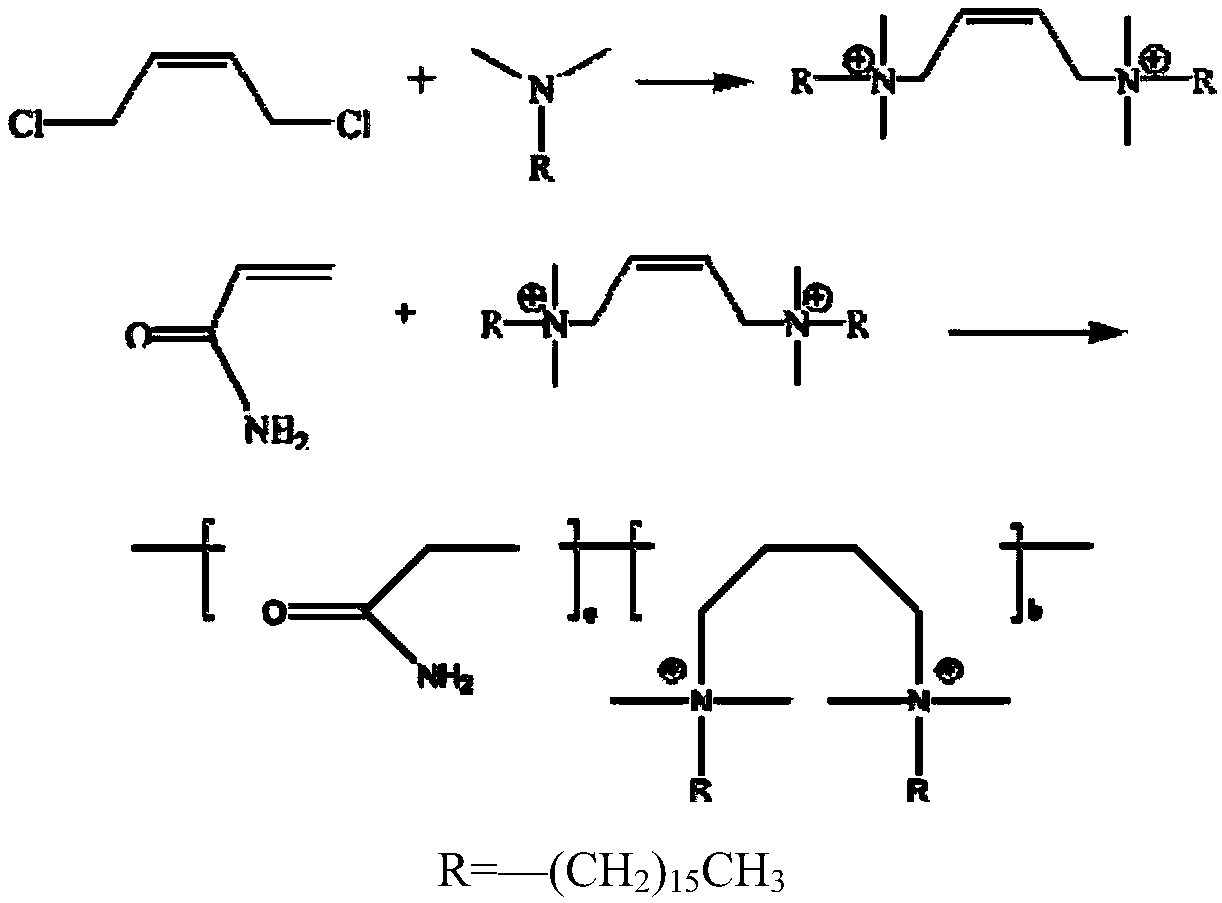

[0050] The synthesis of embodiment 1 double branched cationic hydrophobic monomer

[0051] Weigh according to n(hexadecyldimethyl tertiary amine):n(cis-1,4-dichloro-2-butene)=2.1:1, dissolve in ethanol, pour into a three-necked flask and stir well, Raise the temperature to 60°C and react for 19h. The light yellow product was distilled under reduced pressure, added acetone and placed at 3°C for 3 hours, cooled to crystallize, filtered, washed and dried to obtain CC 16 - White powder of DMBAC.

Embodiment 2

[0052] The synthetic method of the amphiphilic polymer oil displacement agent of embodiment 2 double quaternary ammonium salt long-chain structure

[0053] The CC synthesized in AM and Example 1 16 -DMBAC was added to a three-necked flask at 39°C at a molar ratio of 98:2, a certain mass of distilled water (monomer mass fraction: 20%) was added and stirred evenly, nitrogen gas was introduced for 15 minutes, the temperature was raised to 41°C, and 0.05% of the total monomer was added Fractions of the initiator AIBA, after the reaction, the product was repeatedly washed and purified in acetone, and dried to obtain the amphiphilic polymer DMAPMA with a double quaternary ammonium salt long-chain structure, with a yield of 86.34%.

[0054] Synthetic route such as figure 1 Shown:

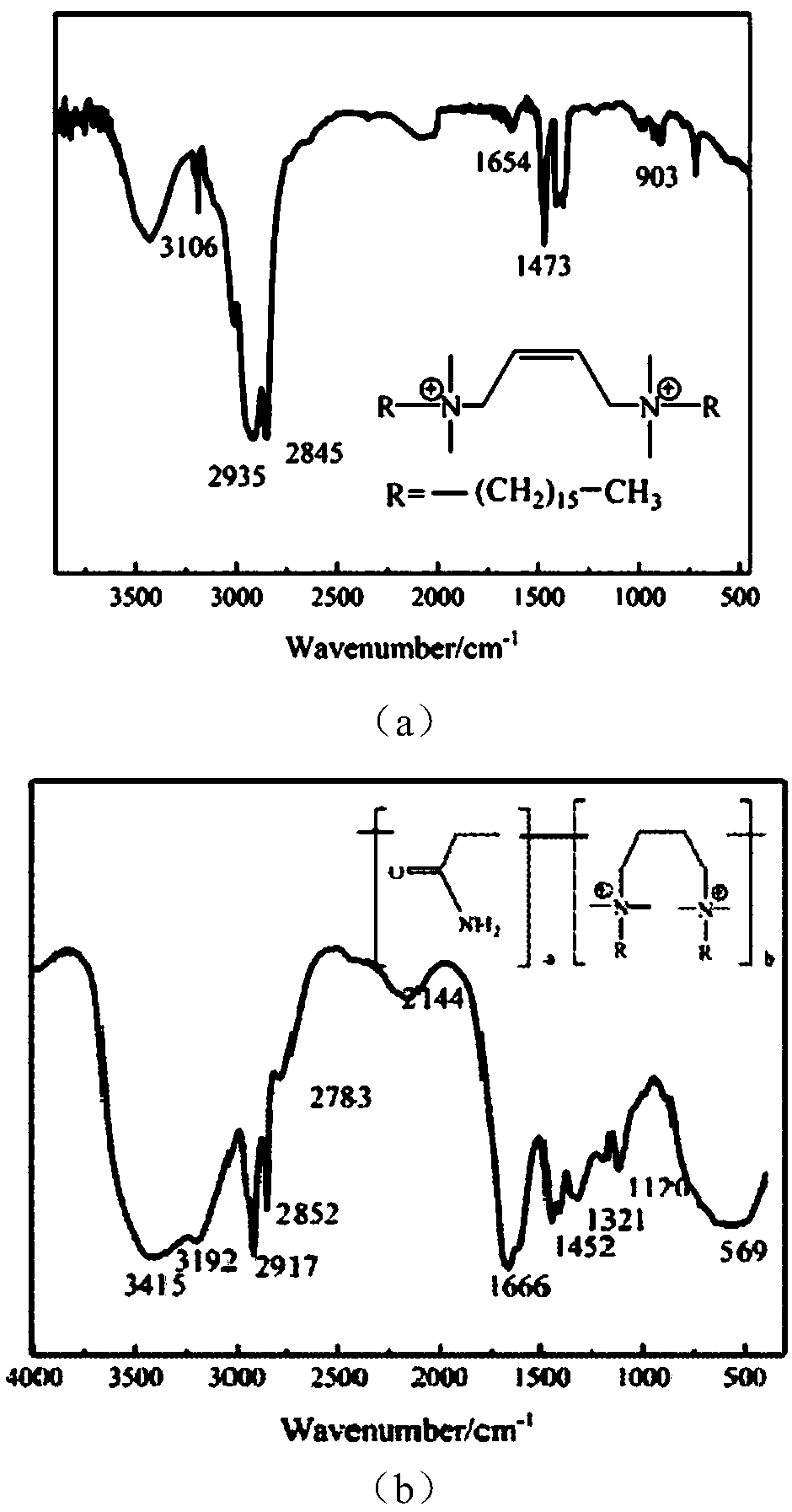

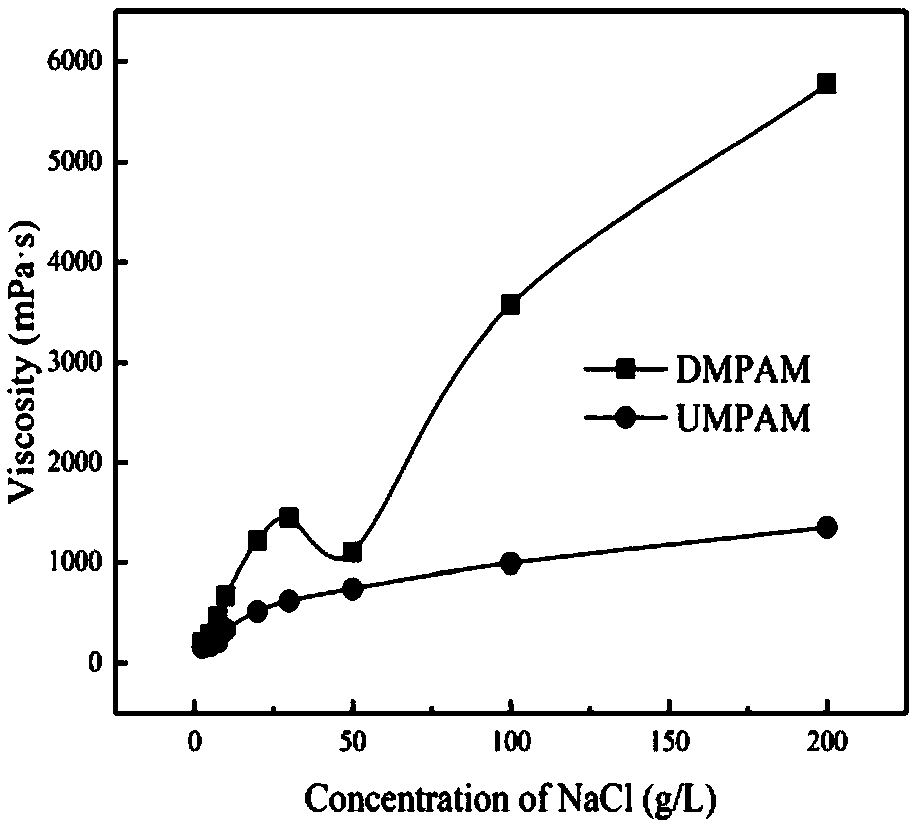

[0055] Characterization and performance of the amphiphilic polymer oil displacement agent with double quaternary ammonium salt long chain structure in embodiment 2

[0056] 1. Infrared characterization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com