High-color-fastness dyeing technology for polyester-cotton knitted fabric

A knitted fabric with high color fastness technology, which is applied in the field of high color fastness dyeing technology, can solve the problems of wasting water and electricity resources, affecting the color fastness of fabrics, and low efficiency. The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

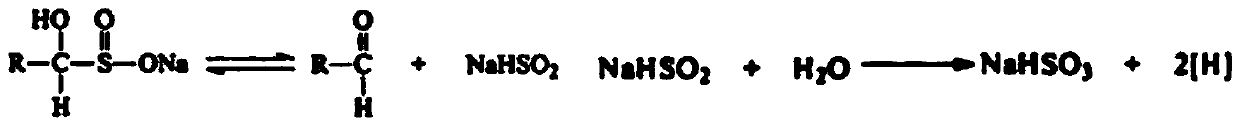

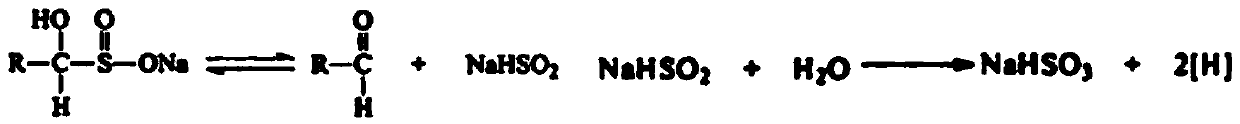

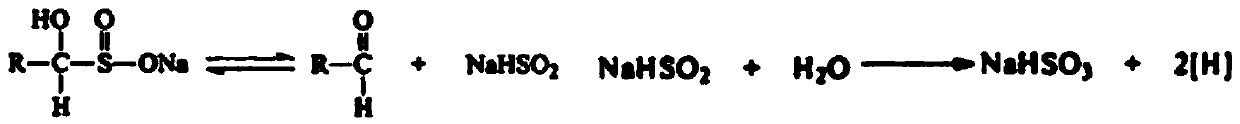

Image

Examples

Embodiment 1

[0041] A kind of high color fastness dyeing process of polyester-cotton knitted fabric, relates to polyester-cotton knitted fabric, comprises the steps:

[0042]S1 Pre-treatment: The polyester-cotton knitted fabric is treated with a pre-treatment solution to remove impurities attached to the fibers and bleached. The temperature is 98°C and the treatment time is 35 minutes. The pre-treatment solution includes 3g / L hydrogen peroxide, 4g / L liquid alkali, and cleaning agent. 1.5g / L;

[0043] S2 primary dyeing: Dye the polyester-cotton knitted fabric with anthraquinone disperse dyes, enter the dyeing at 40°C, raise the temperature to 90°C at a rate of 2°C / min, then raise the temperature to 130°C at a rate of 1°C / min, and keep the temperature for 45 minutes. Anthraquinone disperse dyes are added with 2g / L o-phenylphenol;

[0044] S3 cleaning: peel off the floating color on the polyester-cotton knitted fabric with a cleaning agent, the concentration of the cleaning agent is 1.7g / L, ...

Embodiment 2

[0063] A kind of high color fastness dyeing process of polyester-cotton knitted fabric, relates to polyester-cotton knitted fabric, comprises the steps:

[0064] S1 Pre-treatment: The polyester-cotton knitted fabric is treated with a pre-treatment liquid to remove impurities attached to the fibers and bleached. The temperature is 97°C and the treatment time is 30 minutes. The pre-treatment liquid includes 2.5g / L hydrogen peroxide, 3g / L liquid alkali, washing Dosage 1g / L;

[0065] S2 primary dyeing: Dye the polyester-cotton knitted fabric with anthraquinone disperse dyes, enter the dyeing at 40°C, raise the temperature to 90°C at a rate of 2°C / min, then raise the temperature to 125°C at a rate of 1°C / min, and keep the temperature for 40 minutes. Anthraquinone disperse dyes are added with 2g / L o-phenylphenol;

[0066] S3 cleaning: peel off the floating color on the polyester-cotton knitted fabric with a cleaning agent, the concentration of the cleaning agent is 1.5g / L, the temp...

Embodiment 3

[0085] A kind of high color fastness dyeing process of polyester-cotton knitted fabric, relates to polyester-cotton knitted fabric, comprises the steps:

[0086] S1 Pre-treatment: The polyester-cotton knitted fabric is treated with the pre-treatment liquid to remove the impurities attached to the fibers and bleached. The temperature is 99°C and the treatment time is 40 minutes. Dosage 2g / L;

[0087] S2 primary dyeing: Dye the polyester-cotton knitted fabric with anthraquinone disperse dyes, enter the dyeing at 40°C, raise the temperature to 90°C at a rate of 2°C / min, then raise the temperature to 135°C at a rate of 1°C / min, and keep the temperature for 50 minutes. Anthraquinone disperse dyes are added with 2g / L o-phenylphenol;

[0088] S3 cleaning: peel off the floating color on the polyester-cotton knitted fabric with a cleaning agent, the concentration of the cleaning agent is 2g / L, the temperature is 98°C, the treatment time is 10min, and the liquor ratio is 1:6;

[0089]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com