Graphene composite heat dissipation film and preparation method thereof

A technology of graphene composite and heat dissipation film, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problem that graphene heat-conducting film cannot be prepared with high-quality heat-conducting film, achieve good dispersion and reduce operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

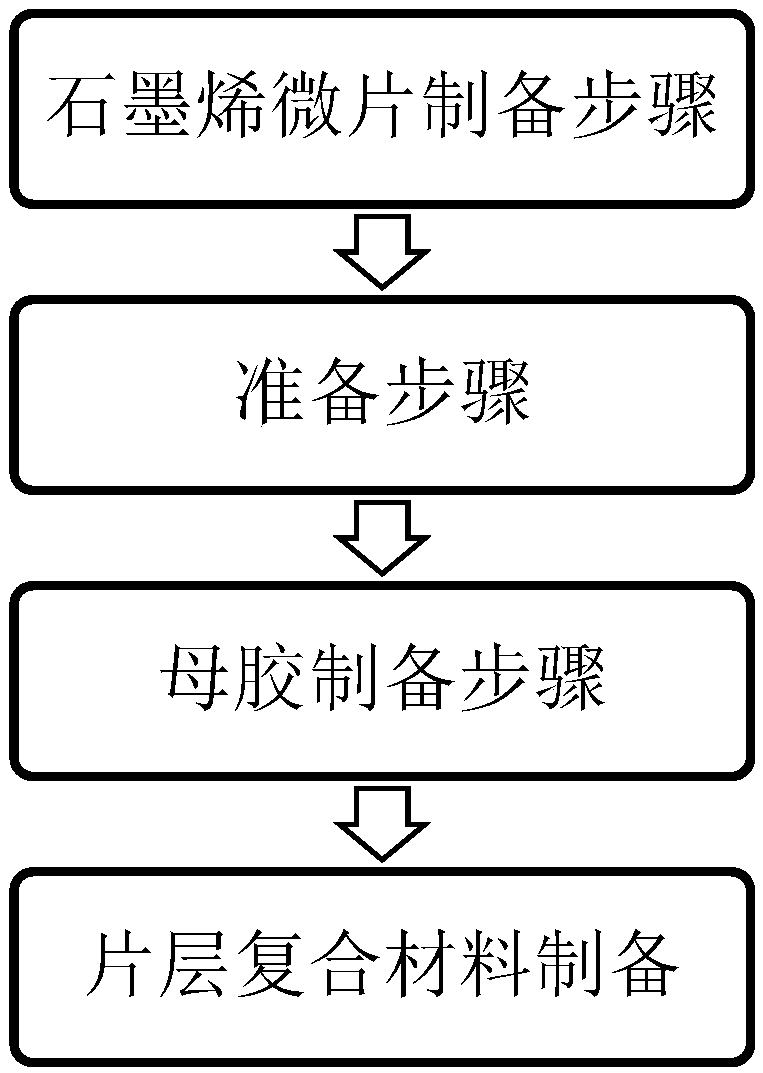

[0016] A kind of graphene composite cooling film and preparation method thereof, it has prepared the graphene composite cooling film as claimed in claim 4, is characterized in that, comprises the following steps: 1) graphene microchip preparation step: with prefabricated a large amount of expansion Graphene flakes are used as raw materials, and the graphene microflake dispersion is generated by high-frequency ultrasonic peeling in absolute ethanol for more than 1-2 hours; the solvent absolute ethanol of the graphene microflake dispersion is supplemented to more than 200-300ml, and the high-strength Sonicate for 3-5 minutes, immediately discard half of the dispersion in the upper layer, and then replenish to a volume of 200-300ml or more, repeat the above process at least 5-10 times, until some samples are taken and observed by SEM or AFM. The average radial size is higher than 5-10um; all solvents are evaporated by rotary evaporation to obtain graphene microplates with large ra...

Embodiment 2

[0021] As in the method given in Example 1, in step (1), the solvent absolute ethanol of the graphene microchip dispersion is supplemented to more than 220ml, high-intensity ultrasonic vibration is performed for 4min, and half of the dispersion in the upper layer is discarded immediately, and then added To a volume of more than 220ml, repeat the above process at least 8 times until the average radial size of the graphene microflakes is higher than 5um.

[0022] In the step (3), put in 270 parts by weight of anhydrous chloroform after washing and drying, and heat to 26°C at a speed of 3-5 revolutions / second of the stirring bar and keep it, and the graphene sieve bucket The lower surface is a polyurethane porous plate with an average aperture of 100-150um; then use the quantum dot sieve bucket to sieve 0.8 parts by weight of ZnO quantum dots from a certain opening of the four-necked bottle, and the lower surface of the quantum dot sieve bucket is Polyurethane porous plate with a...

Embodiment 3

[0025] As in the method given in Example 1, in step (1), the solvent absolute ethanol of the graphene microchip dispersion is supplemented to more than 270ml, high-intensity ultrasonic vibration is performed for 5min, and half of the dispersion in the upper layer is discarded immediately, and then added To a volume of more than 270ml, repeat the above process at least 10 times until the average radial size of the graphene microflakes is higher than 6um.

[0026]In the step (3), after washing and drying, put 320 parts by weight of anhydrous chloroform, under the speed of 5-7 rpm of the stirring rod, heat to 28 ° C and keep, the graphene sieve bucket The lower surface is a polyurethane porous plate with an average pore diameter of 150-200um; the ZnO quantum dots of 1.2 parts by weight are screened in from a certain opening of the four-necked bottle with a quantum dot sieve bucket, and the lower surface of the quantum dot sieve bucket is Polyurethane porous plate with an average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com