Phase change refrigeration high-power laser thermal management device

A laser and high-power technology, applied in the direction of laser cooling devices, lasers, laser components, etc., can solve problems such as large heat dissipation requirements, and achieve the effects of improving heat exchange efficiency, reducing volume, improving performance and environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the implementation of the present invention, further description will be given below in conjunction with specific examples.

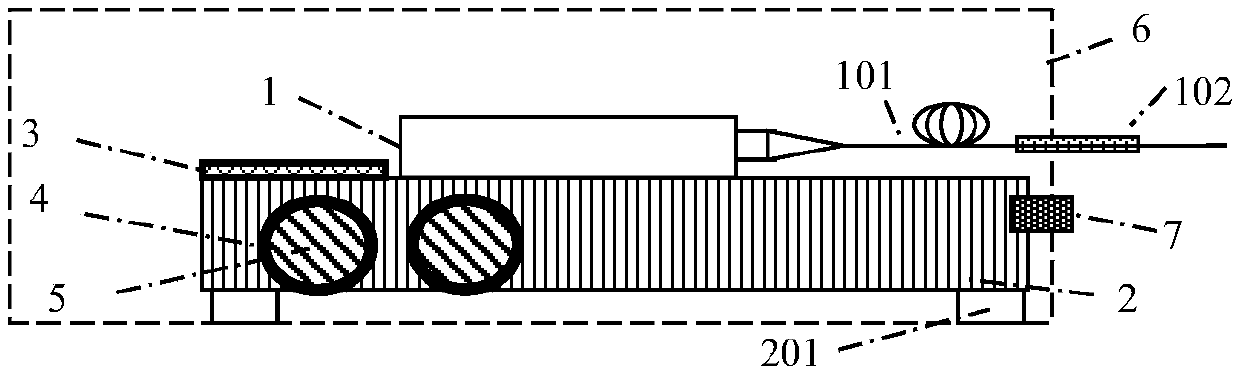

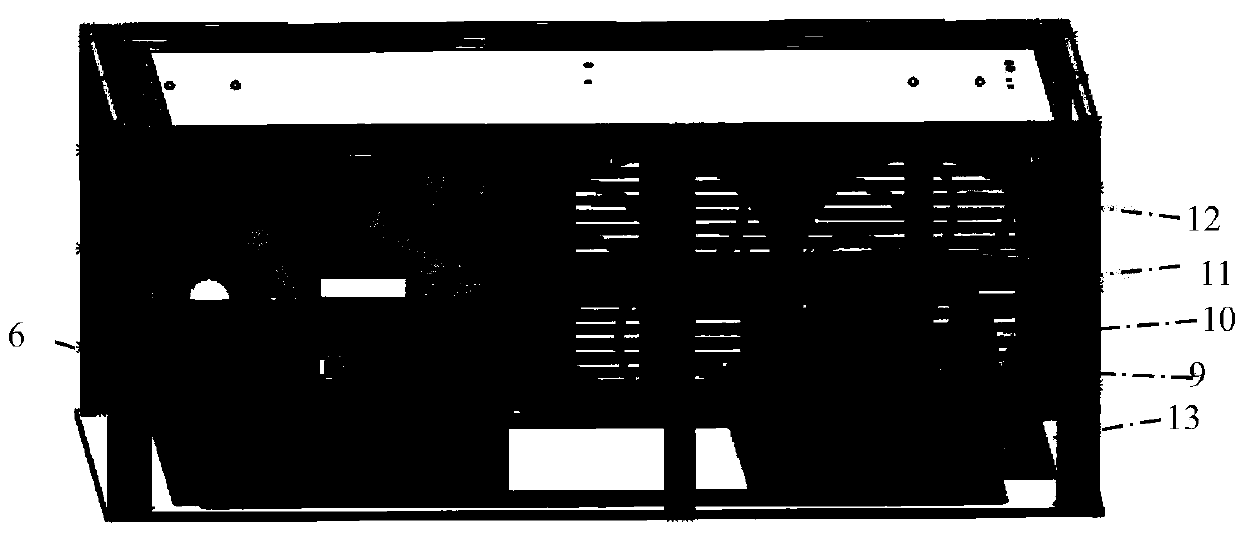

[0028] Such as figure 1 A thermal management device for a phase-change cooling high-power laser is shown, including a housing 6 , an evaporator 2 , a heater 3 , a laser 1 and an output optical fiber 101 . The laser 1 is used to generate high-power laser, and the evaporator 2 is used to provide the low temperature environment required by the laser 1 . The shell 6 is used to insulate the heat convection, maintain the temperature of the laser 1 and the evaporator 2, so that it is not affected by the external temperature, the shell 6 can be made of metal material or ceramic material, or can be made of double-layer glass or glass fiber Or other devices that specifically perform the same function.

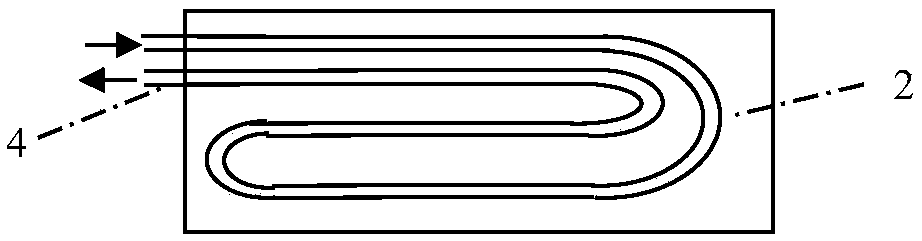

[0029] Specifically, the evaporator 2 is made of metal materials, such as splicing aluminum alloy flat plates or titanium alloy fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com