Interdigital longitudinal magnetic mode drift tube linear accelerator of separation focusing type

A linear accelerator and drift tube technology, which is applied in the direction of linear accelerators, accelerators, electrical components, etc., can solve the problems of low installation accuracy, large deviation between the center of the drift tube and the design value, and jamming, etc., to improve acceleration efficiency, The structure of the cavity is simple, and the effect of accelerating the gradient is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

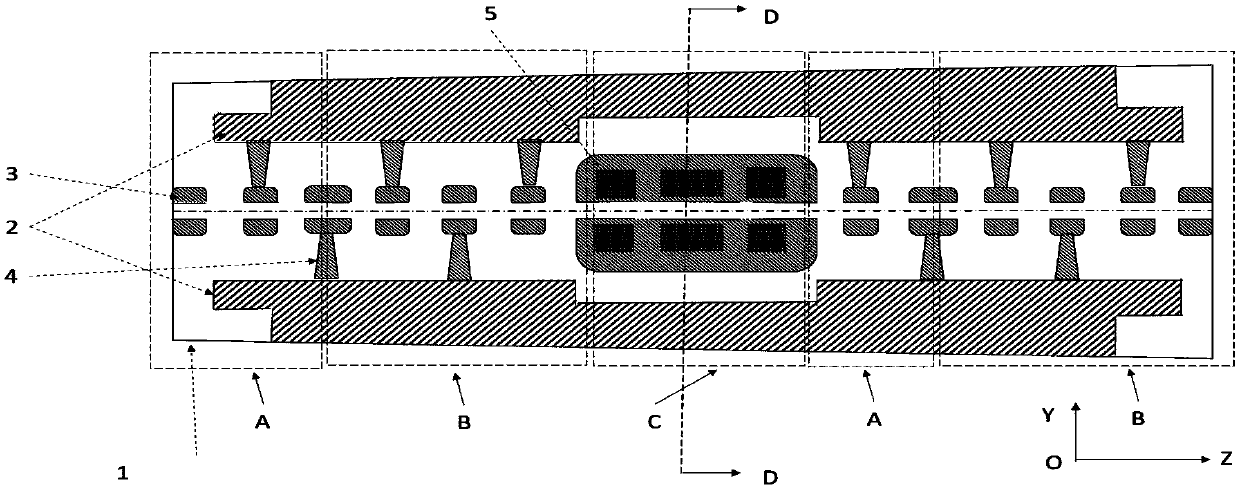

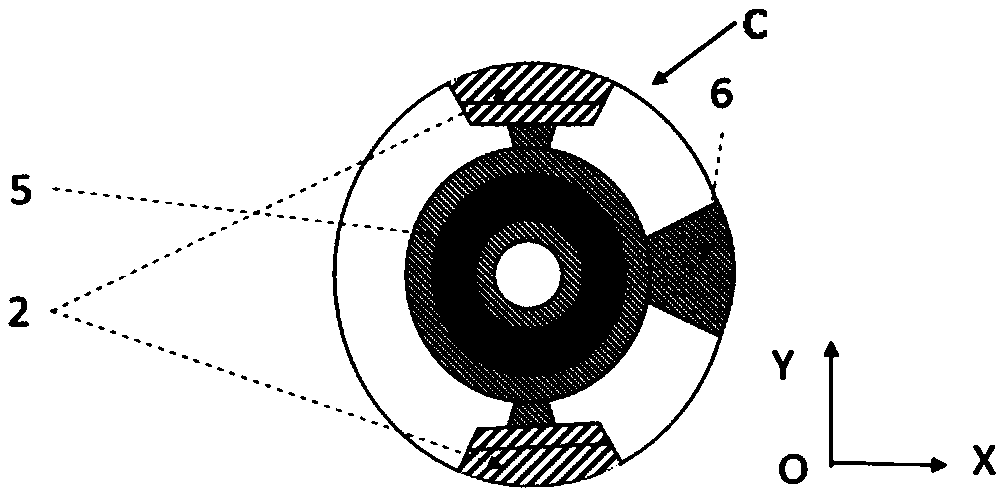

[0033] see image 3 , Figure 4 , a kind of separated focusing type interdigitated longitudinal magnetic mode drift tube linear accelerator of the present embodiment comprises a plurality of drift tubes installed along the central axis of the vacuum radio frequency resonant cavity 1, above and below (or left and right) of the vacuum radio frequency resonant cavity ) is laterally symmetrically provided with a pair of ridge structures 2; the linear accelerator is divided into a longitudinal focusing section A, a 0° accelerating section B, a transverse focusing section C along the forward direction of the incident particle beam, a longitudinal focusing section A, a 0° accelerating section B and a Adjacent drift tubes in the transverse focusing section C (in the figure, the drift tubes in the longitudinal focusing section A and the 0° acceleration section B are denoted by "3", and the drift tubes in the transverse focusing section C are denoted by "30") respectively The support r...

Embodiment 2

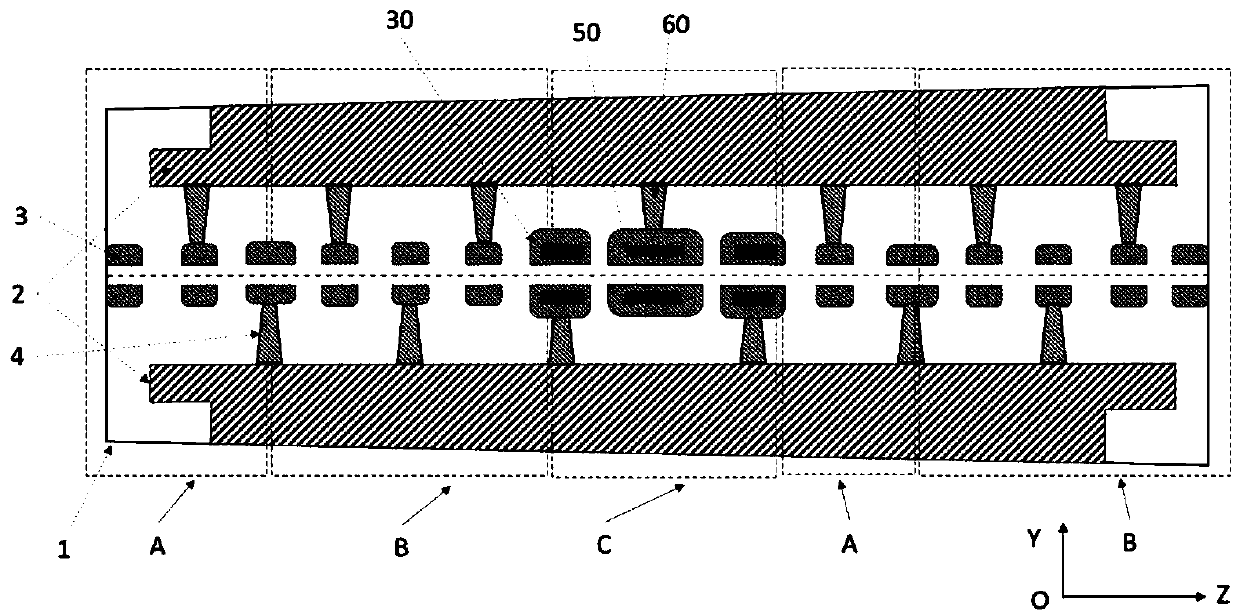

[0051] In this embodiment, on the basis of Embodiment 1, the transverse focusing section C is further improved. In this embodiment, the transverse focusing section C is provided with four drift tubes 30 at intervals, and each drift tube 30 is respectively provided with One permanent magnet quadrupole magnet 50, the magnetic center of each permanent magnet quadrupole magnet 50 coincides with the mechanical center of the drift tube, and the four permanent magnet quadrupole magnets 50 are arranged in the form of focus-divergence-divergence-focus (FDDF), see Figure 7 . Compared with Embodiment 1, this embodiment adopts the FDDF form of focusing structure, and divides the transverse focusing section into four drift tube structures. In this embodiment, the size of the four permanent quadrupole magnets is the same as that of the gradient, and only one A permanent quadrupole magnet is sufficient, and the processing and preparation process of the magnet is simplified under the condit...

Embodiment 3

[0053] In this embodiment, on the basis of Embodiment 2, the transverse focusing section C and the longitudinal focusing section A of the KONUS drift tube linear accelerator are combined, see Figure 8 . The core concept of KONUS drift tube linear accelerator design is segmented, through segmented design, the size of the drift tube in the longitudinal focusing section and 0° acceleration section is small, and the advantage of high shunt impedance of the interdigitated drift tube linear accelerator is maintained. In combination with the split transverse focusing section scheme proposed in Embodiment 2 of the present invention, the synchronous phase of the drift tube gap in the transverse focusing section C is set in the following manner: the longitudinal phase diagram of the bundle in the transverse focusing section C satisfies the following The longitudinal acceptance requirement of the subsequent 0° acceleration section B (the synchronous phase is generally set at about -35°)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com