Preparation method of tubular membrane with composite structure

A composite structure and tubular membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficult distribution and expensive inorganic materials, so as to simplify the membrane preparation process and reduce the economic cost. cost, effect of avoiding layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

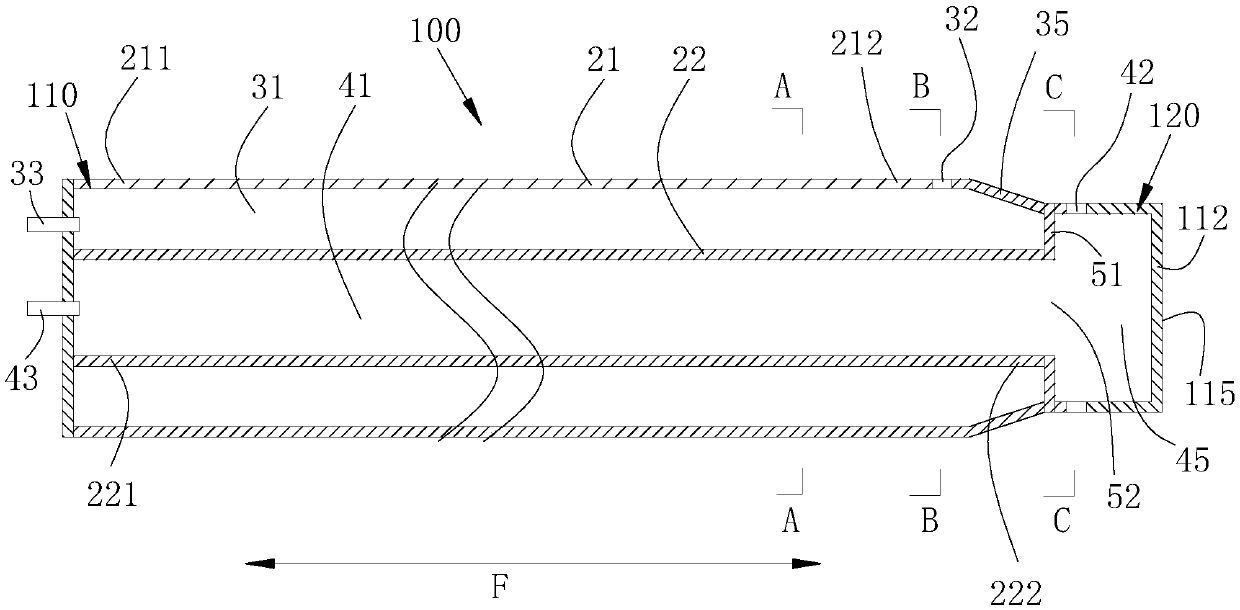

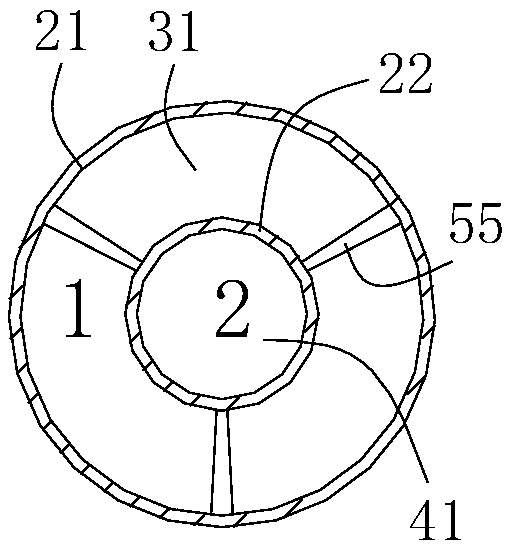

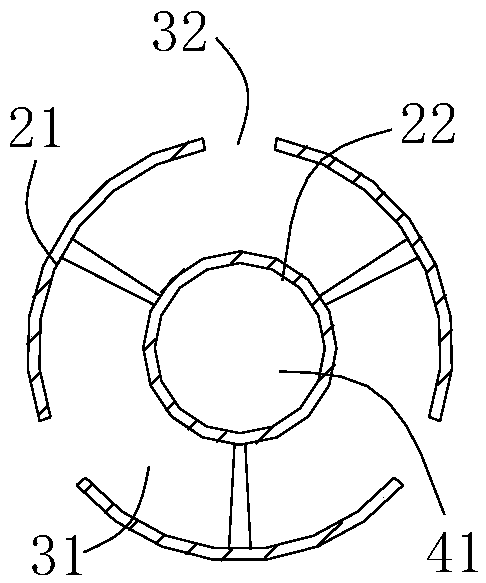

[0051] According to mass percentage, with 17% PVDF, 74% DMAc, 6% PVP K12 and 3% LiCl, at 70 ℃ with a stirring speed of 400rpm stirring for 18h, to obtain the functional layer casting solution; according to mass percentage, 15% of PVDF, 5% of PVP K12, 2.5% of LiCl and 77.5% of DMAc were mixed, and stirred at 70°C for 18 hours at a stirring speed of 400rpm to obtain the supporting layer casting solution; the functional layer casting solution and the supporting layer After the casting solution is left to stand for degassing for 24 hours, it is placed on a tube-type film scraping machine together with the pretreated non-woven roll tube, and the functional layer casting solution and the supporting layer casting solution are passed through the above-mentioned scraping head 100, Coating and film making are carried out at 50°C, the feed rate of the supporting layer casting solution is 3ml / min, the feeding rate of the functional layer casting solution is 0.8ml / min, the coiling speed is ...

Embodiment 2

[0059] According to mass percentage, 20% PAN, 2.5% PEG 400, 77.5% DMAc were insulated and stirred at 70°C for 24h at a stirring speed of 400rpm to obtain a functional layer casting solution; according to mass percentage, 17% PAN, 3% of PVP K15, 2.5% of LiCl and 77.5% of DMAc were mixed, and stirred at 70° C. with a stirring speed of 400 rpm for 24 hours to obtain the supporting layer casting solution; the functional layer casting solution and the supporting layer casting solution were statically After defoaming for 24 hours, place the pretreated non-woven roll tube on a tube-type film scraping machine, pass the functional layer casting solution and the support layer casting solution through the above-mentioned scraping film head 100, and coat at 50°C. For film coating, the feed rate of the supporting layer casting solution is 3.5ml / min, the feeding rate of the functional layer casting solution is 1.0ml / min, the tube rolling speed is 3.0m / min, and the inner diameter of the non-w...

Embodiment 3

[0065] By mass percentage, 2% TiO 2 Mix with 66.5% DMAc, ultrasonically disperse at room temperature for 1 h, add 23% PES, 3.5% SPSf, 2.5% PVP K30 and 2.5% PEG 400, keep stirring at 70°C for 18 h at a stirring speed of 300 rpm, Obtain the functional layer casting liquid; according to the mass percentage, mix 17% PES, 1.5% PVP K30, 1.5% PEG 400 and 80% DMAc, keep stirring at 70°C for 24h at a stirring speed of 400rpm to obtain a support layer Casting solution; the functional layer casting solution and the supporting layer casting solution were left to stand for degassing for 24 hours, and then placed on the tube-type film scraping machine together with the pretreated non-woven roll tube, and the functional layer casting solution and The supporting layer casting solution passes through the above-mentioned scraping film head 100, and is coated and formed at 50°C. The feeding rate of the supporting layer casting solution is 4.0ml / min, and the feeding rate of the functional layer c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com