A preparation method of transparent ceramic self-ligating bracket

A technology of self-locking brackets and transparent ceramics, applied in the direction of brackets, etc., can solve the problems of not being applied in industrial production, long heat preservation time, large fluctuations, etc., achieve excellent water solubility and thermoplasticity, prevent segregation of feeding components, prevent bubbly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] A preparation process for a transparent ceramic self-ligating bracket, the process is as follows:

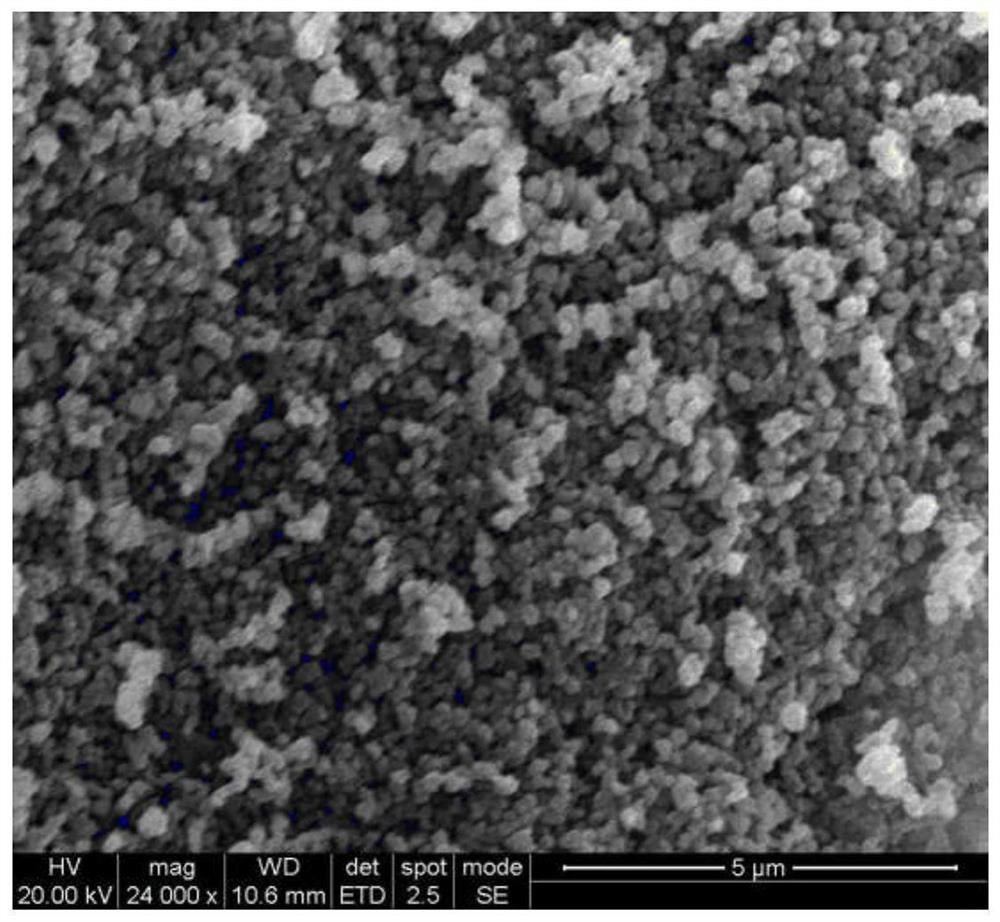

[0043] A. Raw material preparation: The base material is mixed with high-purity alumina powder with an average particle size of 200nm and 0.3% MgO powder provided by Sumitomo Corporation of Japan. The composition of the alumina powder is shown in Table 1. figure 1 It is the SEM topography figure of alumina powder;

[0044] Table 1 Composition of alumina powder

[0045]

[0046] B, preparation of binding agent: according to mass percentage, take polyethylene glycol (PEG) 65%, polyethylene wax (PE wax) 30%, stearic acid (SA) 5%, at 110 ℃ of temperature in the mixer Mix in medium for 4h to make binder;

[0047] C. Preparation of feeding material: mixing and granulating the binder and matrix material according to the volume ratio of 43%:57% to make feeding material. The mixing temperature is 110°C, and the speed of the mixer is 85r / min. The time is 4h;

[0048] D. Inje...

example 2

[0053] A preparation process for a transparent ceramic self-ligating bracket, the process is as follows:

[0054] A. Raw material preparation: the matrix material uses high-purity alumina powder with an average particle size of 200nm and 0.2% MgO+0.2% Y 2 o 3 Powder mixing, the composition of alumina powder is shown in Table 1, figure 1 It is the SEM topography figure of alumina powder;

[0055] B, preparation of binding agent: according to mass percentage, get polyethylene glycol (PEG) 68%, polyethylene wax (PE wax) 30%, stearic acid (SA) 2%, at 120 ℃ of temperature in the mixer Mix in medium for 3h to make binder;

[0056] C. Preparation of feeding material: mixing and granulating the binder and base material according to the volume ratio of 45%:55% to make feeding material. The mixing temperature is 120°C, and the speed of the mixer is 90r / min. The time is 3h;

[0057] D. Injection molding: use the injection molding machine to inject the feed into the mold cavity to o...

example 3

[0062] A preparation process for a transparent ceramic self-ligating bracket, the process is as follows:

[0063] A. Raw material preparation: the matrix material uses high-purity alumina powder with an average particle size of 200nm and 0.2% MgO+0.2% La provided by Sumitomo Corporation of Japan. 2 o 3 The composition of the alumina powder is shown in Table 1, and Figure 1 is the SEM morphology of the alumina powder;

[0064] B, preparation of binding agent: according to mass percentage, take polyethylene glycol (PEG) 70%, polyethylene wax (PE wax) 28%, stearic acid (SA) 2%, at 130 ℃ of temperature in the mixer Mix in medium for 2h to prepare binder;

[0065] C. Preparation of feeding material: mixing and granulating the binder and base material according to the volume ratio of 48%:52% to make feeding material. The mixing temperature is 130°C, and the speed of the mixer is 100r / min. The time is 2h;

[0066] D. Injection molding: use the injection molding machine to inject ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com