Bonding agent for cubic boron nitride, polycrystalline sintered body and preparation method thereof

A technology of cubic boron nitride and boron nitride polymerization, applied in the field of superhard materials, can solve the problems of poor thermal conductivity and wear resistance of polycrystalline cubic boron nitride, so as to improve thermal conductivity, avoid soft spot effect, and improve Effects of hardness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

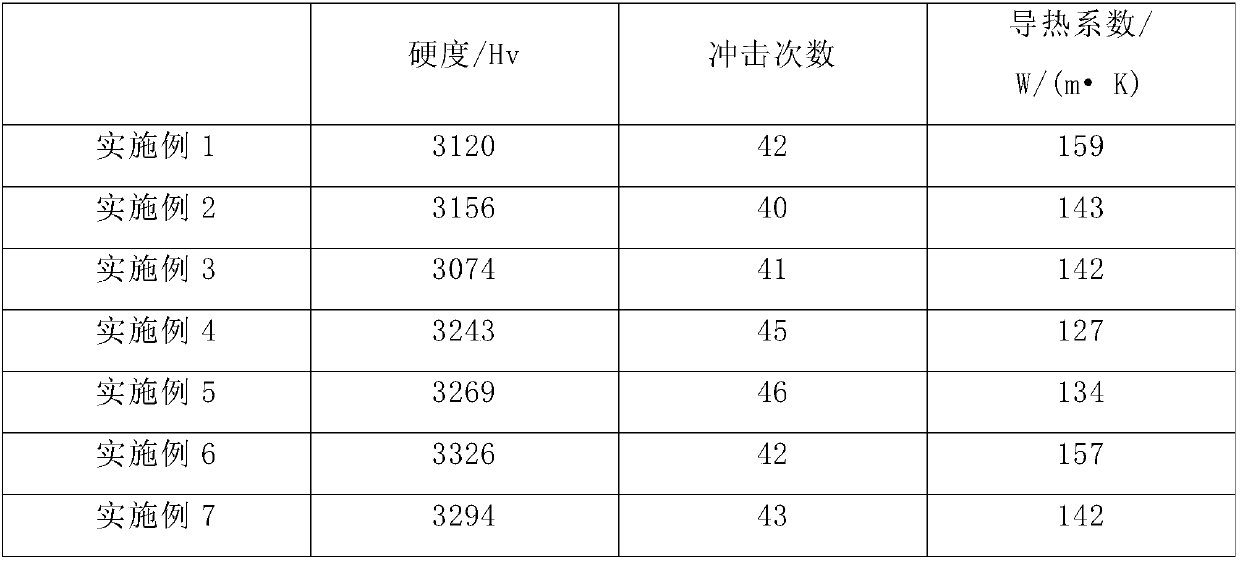

Examples

Embodiment 1

[0019] This embodiment provides a binder for cubic boron nitride, which has an average particle diameter of 300 nm and consists of the following components by mass: 5 parts of metal aluminum, 33 parts of silicon dioxide, 15 parts of nickel oxide, diboron 33 parts of titanium oxide and 15 parts of titanium nitride.

[0020] This embodiment provides a cubic boron nitride polycrystalline sintered body, which includes the following raw materials in parts by mass: 70 parts of cubic boron nitride and 30 parts of binder for cubic boron nitride, wherein the cubic boron nitride The average particle diameter of boron is 10 μm.

[0021] This embodiment provides a method for preparing the cubic boron nitride polycrystalline sintered body, which includes the following steps:

[0022] Mixing the binder for the cubic boron nitride and the cubic boron nitride uniformly to prepare a mixed material;

[0023] Under the condition of 60MPa, press the mixed material into a green body to obtain a ...

Embodiment 2

[0026] This embodiment provides a binder for cubic boron nitride. Its average particle diameter is 267nm, and it is composed of the following components by mass: 3 parts of metal aluminum, 27 parts of silicon dioxide, 5 parts of nickel oxide, diboron 45 parts of titanium oxide, 5 parts of titanium nitride, 7 parts of metal magnesium and 1 part of graphene powder; wherein, the particle diameter of the graphene powder is 26-38nm.

[0027] This embodiment provides a cubic boron nitride polycrystalline sintered body, which includes the following raw materials in parts by mass: 60 parts of cubic boron nitride and 40 parts of binder for the cubic boron nitride; wherein, the cubic boron nitride The average particle size of boron is 7 μm.

[0028] This embodiment provides a method for preparing the cubic boron nitride polycrystalline sintered body, which includes the following steps:

[0029] Mixing the binder for the cubic boron nitride and the cubic boron nitride uniformly to prepa...

Embodiment 3

[0033] This embodiment provides a binder for cubic boron nitride, which has an average particle diameter of 200 nm and consists of the following components by mass: 3 parts of aluminum metal, 32 parts of silicon dioxide, 12 parts of nickel oxide, diboron 40 parts of titanium oxide, 12 parts of titanium nitride, 3 parts of metal magnesium and 1.8 parts of graphene powder; wherein, the particle diameter of the graphene powder is 26-38nm.

[0034] This embodiment provides a cubic boron nitride polycrystalline sintered body, which includes the following raw materials in parts by mass: 80 parts of cubic boron nitride and 20 parts of binder for the cubic boron nitride; wherein, the cubic boron nitride The average particle diameter of boron is 3 μm.

[0035] This embodiment provides a method for preparing the cubic boron nitride polycrystalline sintered body, which includes the following steps:

[0036] Mixing the binder for the cubic boron nitride and the cubic boron nitride unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com