Tunnel excavation anti-collapse slurry

A technology for tunnel excavation and collapse prevention, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of unstable performance, high filtration loss, jamming, etc. The effect of water absorption and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: The anti-collapse grout for tunnel excavation in this embodiment is poured on the excavation surface during tunnel shield excavation, so that a mud film is formed on the excavation surface and excavated objects to support the front soil.

[0015] The tunnel excavation anti-slump grout provided by this embodiment for the clay with high sodium content in the excavated soil layer includes non-dispersible polymer liquid, which includes the following components, and the weight percentages of each component are respectively: bentonite is 1.5-2%, hydrolyzed polyacrylamide PHPA is 0.1-0.2%, soda ash Na 2 co 3 3%-4%, polyacrylamide potassium salt K-PAM 0.1-0.2%, anionic surfactant CMC-LV 0.5%-0.6%, hydrolyzed polyacrylonitrile potassium salt KPAN 0.3-0.5%, and the rest water.

[0016] Among them, the molecular weight of hydrolyzed polyacrylamide PHPA is 1 million to 3 million, and the degree of hydrolysis is 30%, which can inhibit the dispersion of suspended soli...

Embodiment 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the soil quality of the excavated soil layer in this embodiment contains clay with high calcium content, and the tunnel excavation anti-collapse slurry provided by it is compared with the implementation The difference of the tunnel excavation anti-collapse slurry in example one is: soda ash Na 2 co 3 5%-7%. This is because, in order to fully prehydrate the bentonite, more soda ash needs to be added to the soil layer with high calcium content than the soil layer with high sodium content to increase the pulping rate, thereby ensuring that the bentonite can improve viscosity and reduce filtration. lost effect.

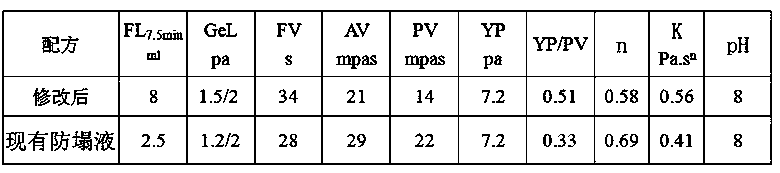

[0021] When implementing the above-mentioned embodiments: after the anti-collapse liquid for tunnel excavation is configured, the properties of the base slurry should be adjusted to the following ranges: funnel viscosity 20-35s; density 1.02-1.03g / cm 3 ; API filtration loss of 7-15ml, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com