Lubricating oil production residue recovery method

A recovery method and technology for lubricating oil, applied in the direction of petroleum wax recovery, etc., can solve the problems of low wax purity, poor deoiling effect, inconvenient utilization, etc., and achieve the effect of improving the oil-supporting effect, improving the de-oiling efficiency and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

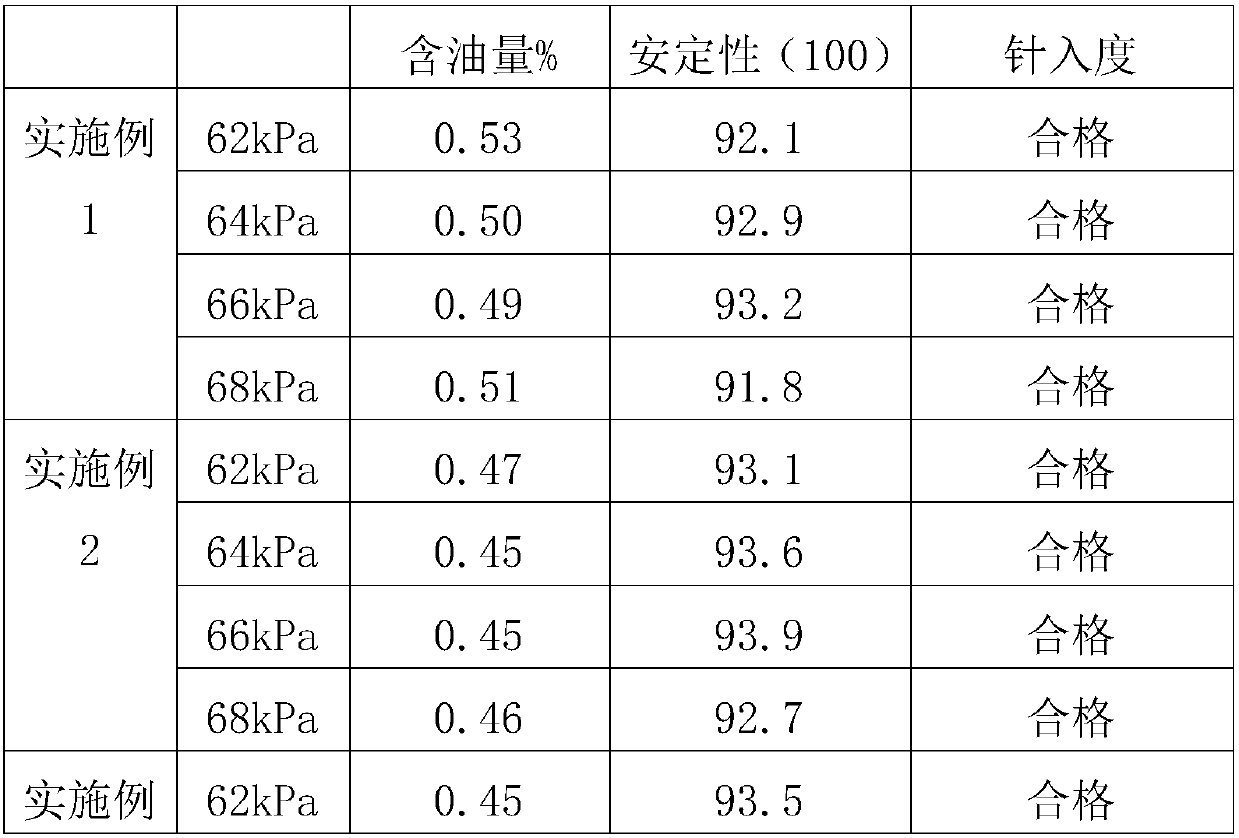

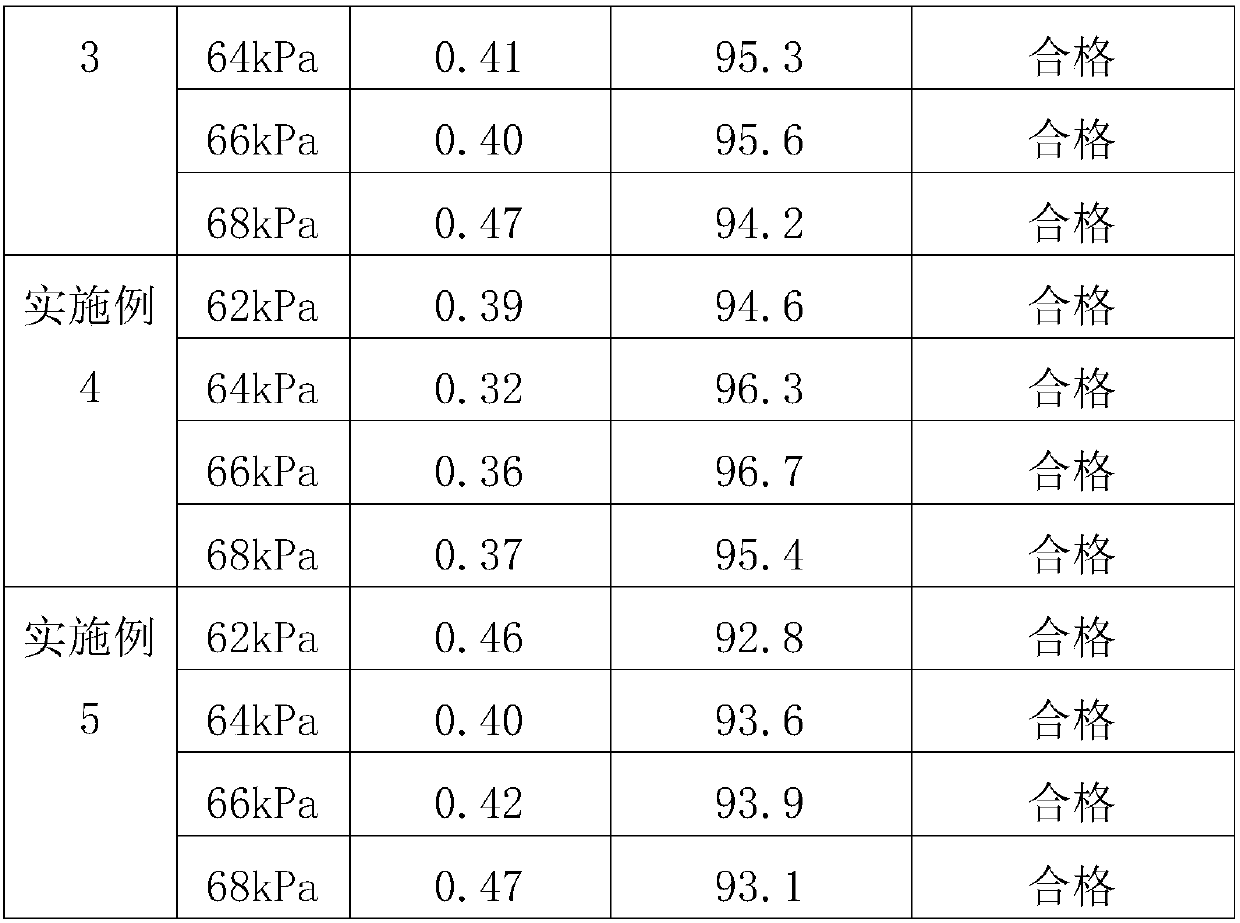

Embodiment 1

[0021] Heat the separated wax paste to 60°C to fully melt, and add a lubricating oil solvent composed of 40% toluene, 20% acetone and 40% methyl ethyl ketone to it, mix well, and mix the material evenly Cool down to 30°C to precipitate the wax, and filter to separate the precipitated paraffin crystals, heat and evaporate the filtered solution to recover the solvent, heat the separated paraffin crystals to 60°C to melt again and pass through at high temperature The high-pressure nozzle is sprayed into the spray tower, and the pressure in the spray tower is adjusted to 62-68kPa, so that the paraffin droplets are solidified into fine particles, and the lubricating oil solvent is sprayed in the opposite direction to the paraffin particles, so that the lubricating oil solvent and the paraffin particles are fully contacted and carried The oil in the paraffin particles is exported, the solvent carrying the oil is heated and evaporated to recover the solvent, and the paraffin particles...

Embodiment 2

[0023] Heat the separated wax paste to 60°C to fully melt, and add a lubricating oil solvent composed of 40% toluene, 25% acetone and 35% methyl ethyl ketone to it, mix well, and mix the material evenly Cool down to 30°C to precipitate the wax, and filter to separate the precipitated paraffin crystals, heat and evaporate the filtered solution to recover the solvent, heat the separated paraffin crystals to 60°C to melt again and pass through at high temperature The high-pressure nozzle is sprayed into the spray tower, and the pressure in the spray tower is adjusted to 62-68kPa, so that the paraffin droplets are solidified into fine particles, and the lubricating oil solvent is sprayed in the opposite direction to the paraffin particles, so that the lubricating oil solvent and the paraffin particles are fully contacted and carried The oil in the paraffin particles is exported, the solvent carrying the oil is heated and evaporated to recover the solvent, and the paraffin particles...

Embodiment 3

[0025] Heat the separated wax paste to 60°C to fully melt, and add a lubricating oil solvent composed of 40% toluene, 30% acetone and 30% methyl ethyl ketone to it, mix well, and mix the material evenly Cool down to 30°C to precipitate the wax, and filter to separate the precipitated paraffin crystals, heat and evaporate the filtered solution to recover the solvent, heat the separated paraffin crystals to 60°C to melt again and pass through at high temperature The high-pressure nozzle is sprayed into the spray tower, and the pressure in the spray tower is adjusted to 62-68kPa, so that the paraffin droplets are solidified into fine particles, and the lubricating oil solvent is sprayed in the opposite direction to the paraffin particles, so that the lubricating oil solvent and the paraffin particles are fully contacted and carried The oil in the paraffin particles is exported, the solvent carrying the oil is heated and evaporated to recover the solvent, and the paraffin particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com