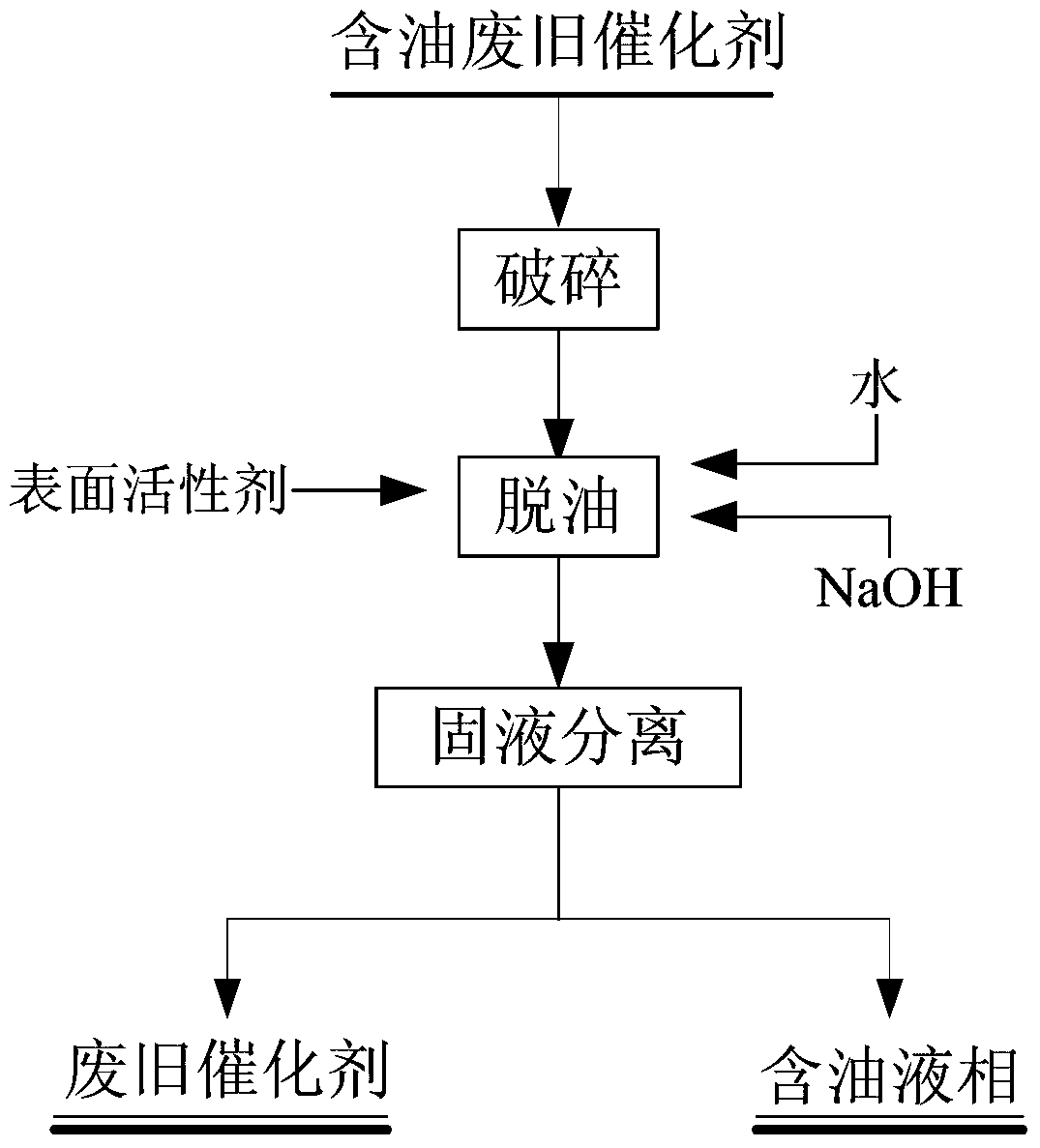

A method for deoiling oily spent catalyst

A waste catalyst and deoiling technology, which is applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve the problems of low leaching rate of valuable metal elements, difficulty in effective control of sintering temperature, and refractory compounding Oxide and other problems, to avoid the formation of composite oxides, avoid greenhouse gas emissions, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, waste Mo-Co / Al 2 o 3 The catalyst is the treatment object, and its oil content (mass percentage content, the same below) is about 20%.

[0021] Through the crushing process, the particle size of the spent catalyst was crushed to 500 μm. The mass ratio of water to spent catalyst is 14:1, and NaOH and sodium dodecylsulfonate are added to the water to reduce the oil-water interfacial tension and promote oil-solid separation. The solid content of NaOH in the mixed solution after adding NaOH and sodium dodecylsulfonate is 2wt%, and the solid content of sodium dodecylsulfonate is 0.1wt% to obtain feed liquid; The feed liquid that configures is placed in 90 In a constant temperature environment of ℃, after stirring for three hours, when the color of the liquid phase does not change, stop stirring and heating; filter while hot to achieve solid-liquid separation. The obtained filter residue is washed twice with hot water at 90° C., and the solid obtained afte...

Embodiment 2

[0023] In this embodiment, waste Mo-Ni / Al 2 o 3 The catalyst is the object of treatment, and its oil content is about 18%.

[0024] Through the crushing process, the particle size of the spent catalyst was crushed to 100 μm. The mass ratio of water to spent catalyst is 8:1, and sodium dodecylsulfonate is used as deoiling surfactant. The solid content of NaOH in the mixed solution after adding NaOH and sodium dodecylsulfonate is 2wt%, and the solid content of sodium dodecylsulfonate is 0.1wt% to obtain feed liquid; In a constant temperature environment of 100°C, stir for four hours. When the color of the liquid phase does not change, stop stirring and heating; filter while hot to achieve solid-liquid separation. The obtained filter residue is washed twice with hot water at 90° C., and the solid obtained after washing can be dried in a drying oven. The removal rate of hydrophobic oil in the waste catalyst can reach more than 98%.

Embodiment 3

[0026] In this example, waste Mo-Co / Al 2 o 3 The catalyst is the object of treatment, and its oil content is about 20%. Sodium dodecylbenzenesulfonate was used as deoiling surfactant.

[0027] Through the crushing process, the particle size of the spent catalyst was crushed to 300 μm. The mass ratio of water to spent catalyst is 10:1, and NaOH and sodium dodecylbenzenesulfonate are added to the water to reduce the oil-water interfacial tension and promote oil-solid separation. The solid content of NaOH in the mixed solution after adding NaOH and sodium dodecylsulfonate is 2wt%, and the solid content of sodium dodecylsulfonate is 0.1wt% to obtain feed liquid; In a constant temperature environment of 90°C, after stirring for three hours, when the color of the liquid phase does not change, stop stirring and heating; filter while hot to achieve solid-liquid separation. The obtained filter residue is washed twice with hot water at 90° C., and the solid obtained after washing ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com