Green and clean fermentation technology of glutamic acid

A fermentation process, glutamic acid technology, applied in the field of green and clean fermentation process of glutamic acid, can solve the problems of large differences in cell membrane structure and irregular rules to follow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The strain used in this experiment is Corynebacterium glutamicum GDK-9 (also known as Brevibacterium flavum GDK-9, which is derived from Tianjin University of Science and Technology. The source of the strain can also be found in "Research on variable temperature control process of L-glutamic acid fermentation, Tianjin Chemical Industry Co., Ltd. year 2010").

[0032] The green clean fermentation technology of glutamic acid, it comprises the steps: Corynebacterium glutamicum GDK-9 is pressed seed liquid (OD 600nm 10) Connect to a 50L fully automatic fermenter equipped with 30L clean fermentation medium for fermentation and cultivation, the fermentation temperature is 38°C, the ventilation ratio is 1:0.7, the stirring speed is 500r / min, the dissolved oxygen is maintained at 20%, and the feed mass Glucose with a percentage concentration of 80% maintains a residual sugar of 1.5%, adding a defoamer to defoam, and the total fermentation time is 33h; wherein, the fermentation ...

Embodiment 2

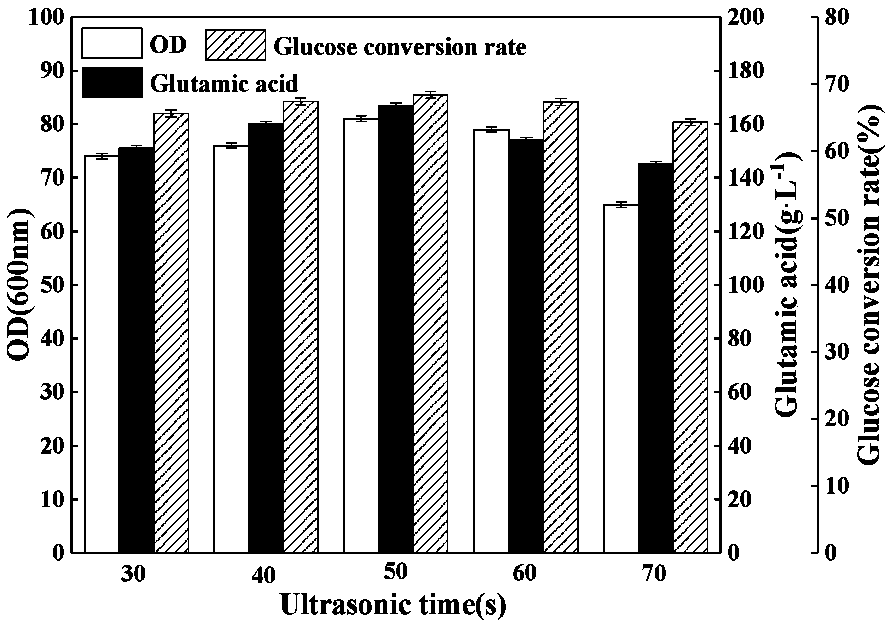

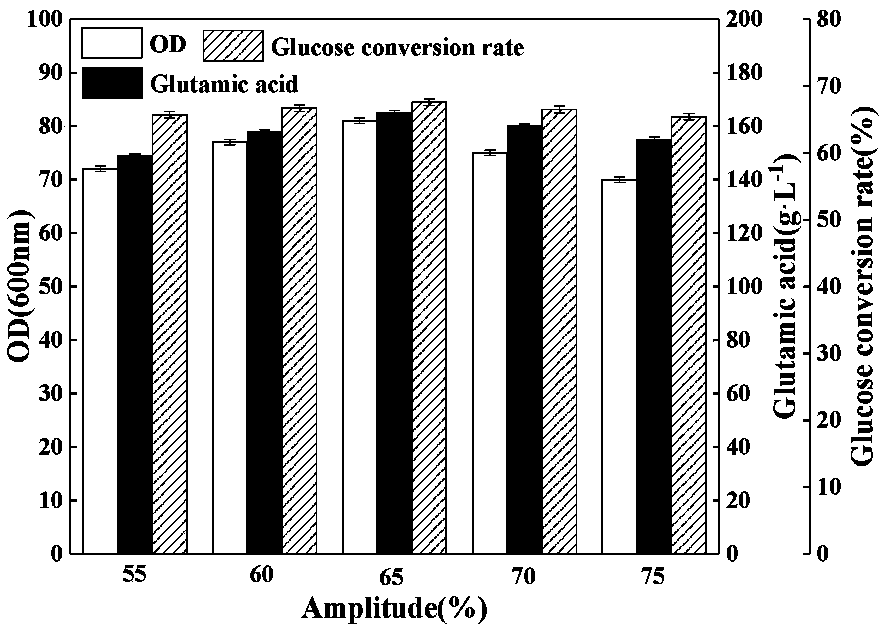

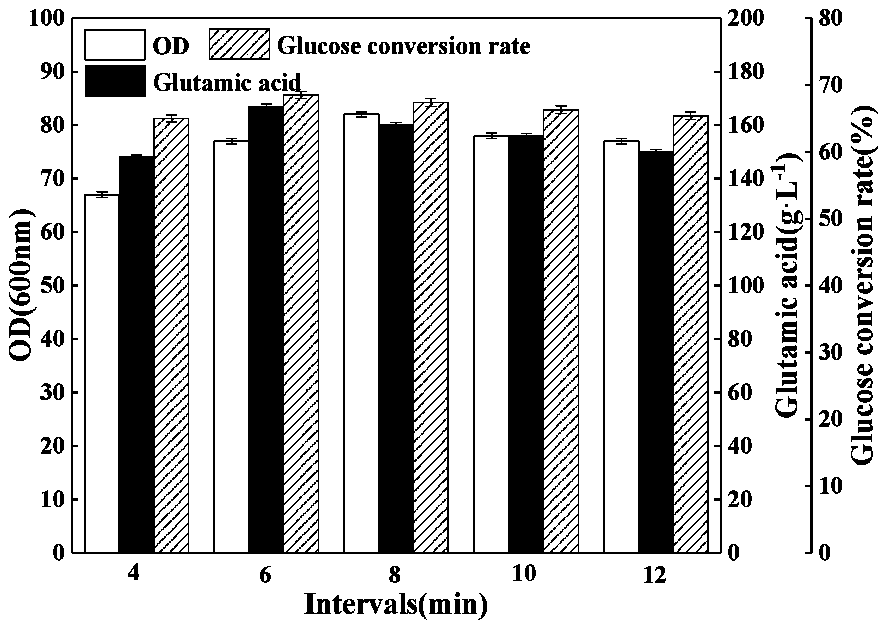

[0042] The green clean fermentation technology of glutamic acid, it comprises the steps: Corynebacterium glutamicum GDK-9 is pressed seed liquid (OD 600nm 14) Connect to a 50L fully automatic fermenter equipped with 30L clean fermentation medium for fermentation and cultivation, the fermentation temperature is 37°C, the ventilation ratio is 1:0.8, the stirring speed is 300-700r / min, and the dissolved oxygen is maintained at 25%. Add glucose with a mass percentage concentration of 80% to maintain the residual sugar at 1%, add defoaming agent to defoam, and the total fermentation time is 34h; among them, the fermentation culture is 0-8h, and a high-temperature resistant ultrasonic probe is inserted in the fermenter. Finally, turn on the ultrasonic controller and perform ultrasonic treatment under certain conditions. The conditions of ultrasonic treatment are: ultrasonic power 500W, frequency 20kHZ, ultrasonic time 50s, amplitude 65%, interval 5min, and adjust by adding 25% ammoni...

Embodiment 3

[0050] Optimization of glutamic acid fermentation medium.

[0051] 1. The effect of the addition amount of bacterial proteolysis liquid on the concentration of bacteria in the fermentation broth and the output of glutamic acid. The addition amount was selected as five concentration gradients of 20, 40, 60, 80, 100, and 120 (ml / L). It was found that with Bacteria in the fermentation broth increased with the addition amount

[0052] Table 1

[0053] Addition amountml / L

Cell OD in fermentation broth 600nm

Glutamic acid production g / L

20

60.7

143.6

40

68.9

152.1

60

75.3

159.8

80

81.8

167.0

100

80.1

163.5

120

76.9

156.9

[0054] Substitute corn steep liquor (10g / L, OD 600nm 65.8, glutamic acid output 151g / L, light transmittance (T 430 ) was 0.98), the data found that with the addition of the cell proteolysis solution, the cell concentration and glutamic acid content a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com