Preparation method of ternary cathode material coated with TiO2 nanofibers of lithium ion battery and product

A lithium-ion battery and nanofiber technology, applied in battery electrodes, electrical components, nanotechnology, etc., can solve the problem of urgent research and development of ternary cathode materials, achieve excellent electrochemical performance, stabilize the structure of ternary materials, and improve electrochemical performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

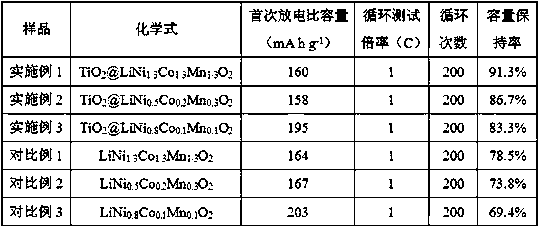

Embodiment 1

[0020] TiO 2 @LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Preparation of cathode material

[0021] 1. Preparation of TiO by electrospinning 2 Nanofiber: Weigh 10ml of liquid tetrabutyl titanate, dissolve it in 30ml of ethylene glycol methyl ether, and stir it by magnetic force to form a tetrabutyl titanate mixed solution. Weigh 5g of polyvinylpyrrolidone (PVP) (Mw=1300000) and add it to 40ml prepared tetrabutyl titanate solution, continue magnetic stirring for 5h to form a uniform light yellow sol-gel precursor solution; put the prepared precursor The solution was put into a syringe with a diameter of 12 mm, placed in an electrospinning device, and the collecting plate was connected to a negative power supply to collect PVP / TiO2 nanofibers. The collected product was calcined at a high temperature of 700° C. for 2 h to obtain TiO2 nanofibers with a pore structure.

[0022] 2. Preparation of TiO 2 @LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Positive electrode material: Lithium acetate, nickel acet...

Embodiment 2

[0024] TiO 2 @LiNi 0.5 co 0.2 mn 0.3 o 2 Preparation of cathode material

[0025] 1. Preparation of TiO by electrospinning 2 Nanofiber: Weigh 8ml of liquid tetrabutyl titanate, dissolve it in 25ml of ethylene glycol methyl ether, and stir it by magnetic force to prepare a tetrabutyl titanate mixed solution. Weigh 4g of polyvinylpyrrolidone (PVP) (Mw=1300000) and add it to 33ml prepared tetrabutyl titanate solution, continue magnetic stirring for 4h to form a uniform light yellow sol-gel precursor solution; put the prepared precursor The solution was put into a syringe with a diameter of 12 mm, placed in an electrospinning device, and the collecting plate was connected to a negative power supply to collect PVP / TiO2 nanofibers. The collected product was calcined at a high temperature of 600° C. for 1 h to obtain TiO2 nanofibers with a pore structure.

[0026] 2. Preparation of TiO 2 @LiNi 0.5 co 0.2 mn 0.3 o 2 Positive electrode material: Lithium acetate, nickel ac...

Embodiment 3

[0028] TiO 2 @LiNi 0.8 co 0.1 mn 0.1 o 2 Preparation of cathode material

[0029] 1. Preparation of TiO by electrospinning 2 Nanofiber: Weigh 5ml of liquid tetrabutyl titanate, dissolve it in 20ml of ethylene glycol methyl ether, and stir it by magnetic force to prepare a tetrabutyl titanate mixed solution. Weigh 3g of polyvinylpyrrolidone (PVP) (Mw=1300000) into 25ml prepared tetrabutyl titanate solution, continue magnetic stirring for 2h to form a uniform light yellow sol-gel precursor; put the prepared precursor The solution was put into a syringe with a diameter of 12 mm, placed in an electrospinning device, and the collecting plate was connected to a negative power supply to collect PVP / TiO2 nanofibers. The collected product was calcined at a high temperature of 500° C. for 1 h to obtain TiO2 nanofibers with a pore structure.

[0030] 2. Preparation of TiO 2 @LiNi 0.8 co 0.1 mn 0.1 o 2 Positive electrode material: Lithium acetate, nickel acetate, cobalt acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com