Preparation method for vanadium pentoxide/graphene composite positive electrode material of high-performance sodium ion battery

A technology for composite cathode materials and sodium-ion batteries, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of low yield, complicated process, difficult control, etc., and achieve high yield and simple preparation method , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

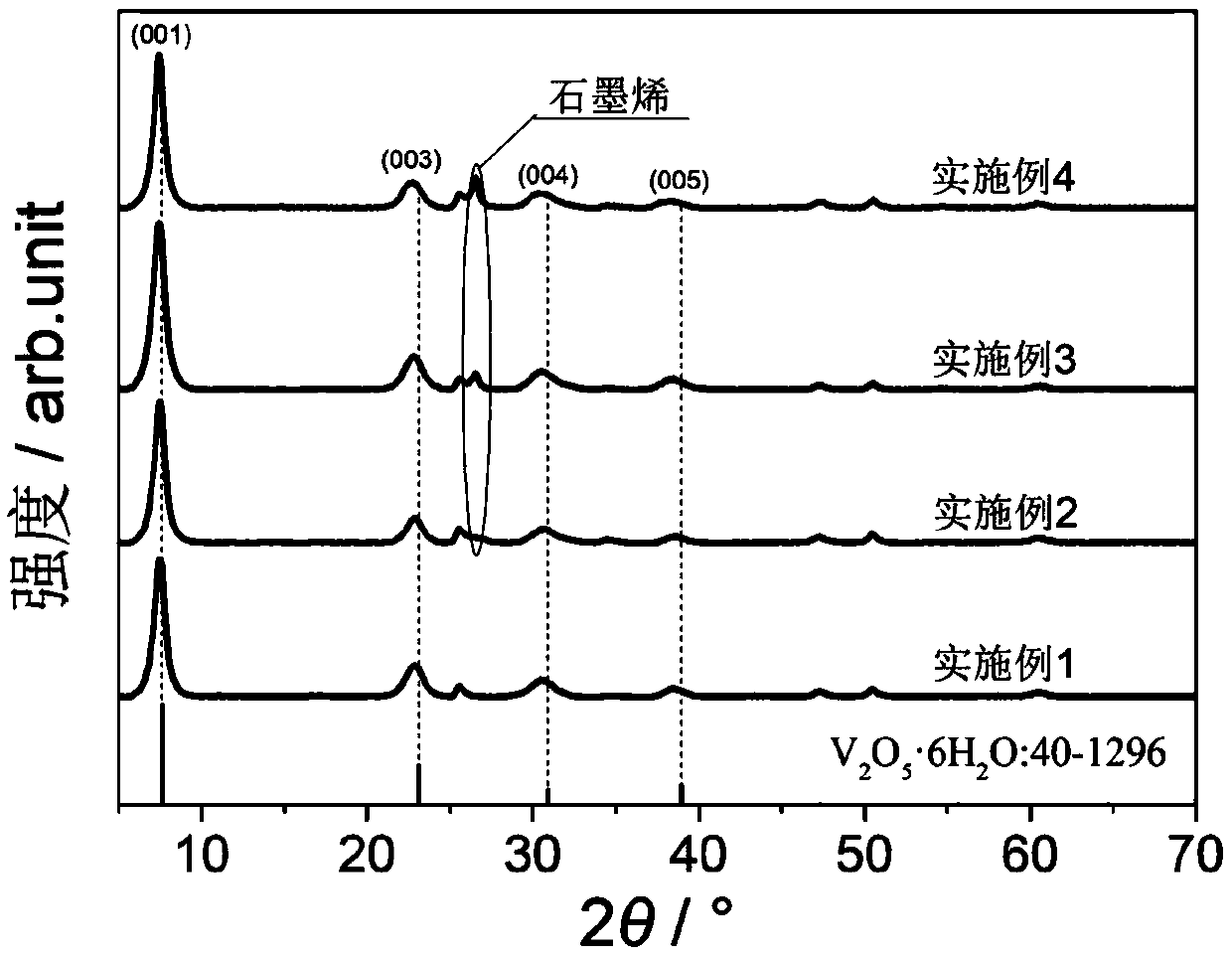

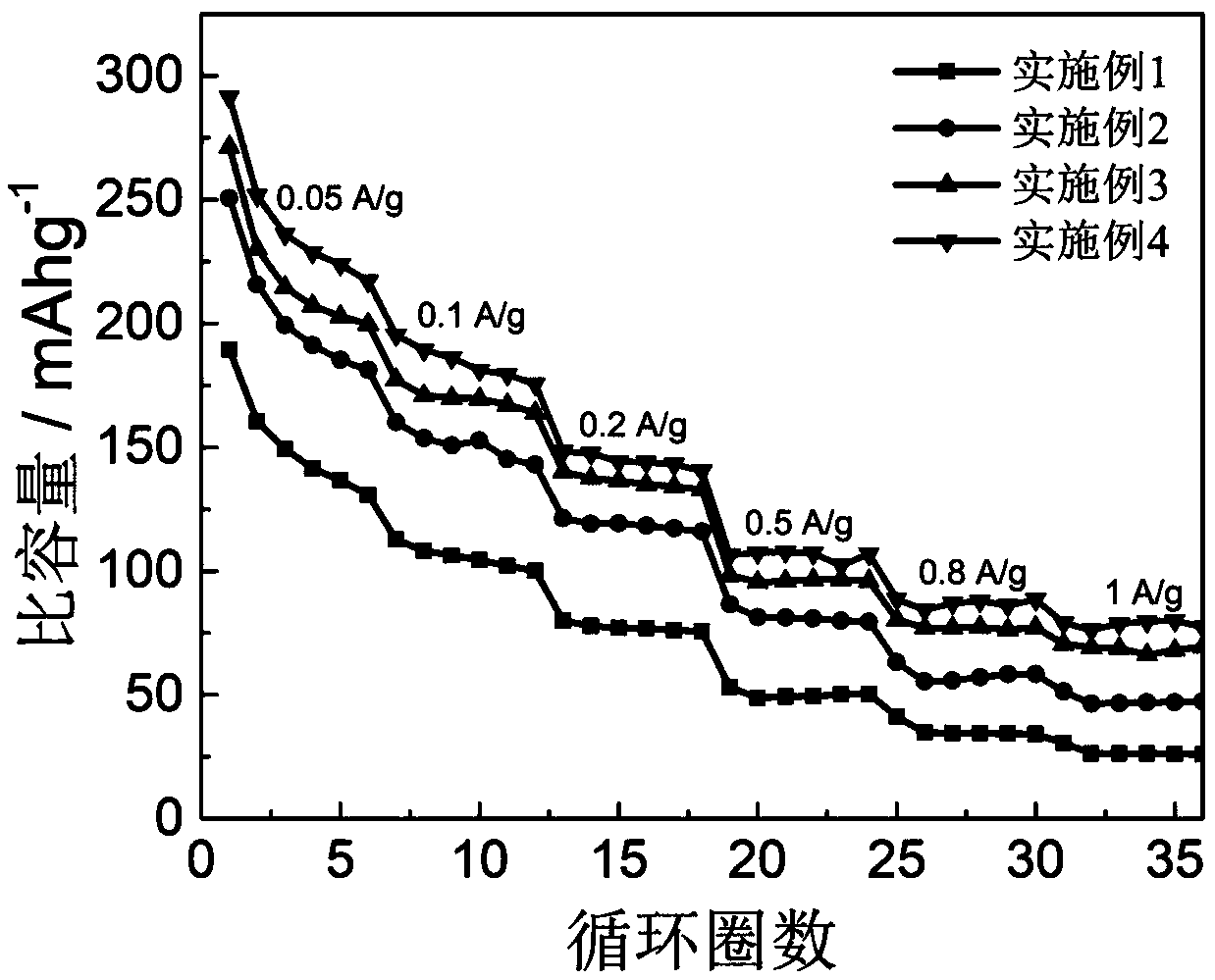

[0017] (1) First, 0.2547g of commercial vanadium pentoxide (V 2 o 5 ) powder and 3.85mL of deionized water were mixed and stirred in a water bath at room temperature for 5 minutes, and 1.15mL of 30% H 2 o 2 , continue to stir for 15 minutes after the dropwise addition is completed, then transfer it to an ultrasonic cleaner and add 20mL deionized water to dilute the solution to the concentration of vanadium pentoxide 0.056mol / L, continue to sonicate for 90 minutes to obtain a greenish-brown gel, leave it to age at room temperature for 3 days, and obtain a reddish-brown V 2 o 5 ·nH 2 O gel.

[0018] (2) The V obtained in step (1) 2 o 5 ·nH 2 O gel was stirred, dispersed, and diluted to the concentration of vanadium pentoxide with 25 mL of deionized water Continue to stir for 6 hours, then transfer the liquid to the refrigerator for freezing for 24 hours and then move to a freeze dryer to dry to constant weight and take out to obtain V 2 o 5 ·nH 2 O electrode materi...

Embodiment 2

[0021] (1) First, 0.2547g of commercial vanadium pentoxide (V 2 o 5 ) powder and 2.55mL mass percent concentration of 5% graphene (Graphene) aqueous dispersion in a water bath at normal temperature after mixing and stirring for 5 minutes, while stirring slowly added 1.15mL mass percent concentration of 30% H 2 o 2 , continue to stir for 15 minutes after the dropwise addition is completed, then transfer it to an ultrasonic cleaner and add 21.3mL deionized water to dilute the solution to the concentration of vanadium pentoxide was 0.056mol / L, continued ultrasonication for 90 minutes, and obtained a black gel, left to age at room temperature for 3 days, and obtained dark brown V 2 o 5 ·nH 2 O / Graphene Gel.

[0022] (2) The V obtained in step (1) 2 o 5 ·nH 2 The O / Graphene gel was stirred, dispersed, and diluted with 25 mL deionized water to Continue to stir for 6 hours, then transfer the liquid to the refrigerator for freezing for 24 hours and then move to a freeze dry...

Embodiment 3

[0025] (1) First, 0.2547g of commercial vanadium pentoxide (V 2 o 5 ) powder and 7.65mL mass percent concentration of 5% Graphene (Graphene) aqueous dispersion in a water bath at normal temperature after mixing and stirring for 5 minutes, while stirring, slowly dripping 1.15mL mass percent concentration of 30% H 2 o2 , continue to stir for 15 minutes after the dropwise addition is completed, then transfer it to an ultrasonic cleaner and add 16.2mL deionized water to dilute the solution to the concentration of vanadium pentoxide was 0.056mol / L, continued ultrasonication for 90 minutes, and obtained a black gel, left to age at room temperature for 3 days, and obtained dark brown V 2 o 5 ·nH 2 O / Graphene Gel.

[0026] (2) The V obtained in step (1) 2 o 5 ·nH 2 The O / Graphene gel was stirred, dispersed, and diluted with 25 mL deionized water to Continue to stir for 6 hours, then transfer the liquid to the refrigerator for freezing for 24 hours and then move to a freeze d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com