Tremella-shaped nanosphere material assembled by inlaying molybdenum dioxide nanoparticles into carbon nanosheet, preparation of tremella-shaped nanosphere material and application of tremella-shaped nanosphere material in sodium ion battery

A carbon nanosheet and nanoparticle technology is applied in the field of molybdenum dioxide nanoparticles inlaid carbon nanosheets to assemble tremella-like nanosphere materials, which can solve the problems of low space utilization, high volume energy density, large size, etc. Effects of chemical activity, high specific capacity, stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 30 mg of ammonium molybdate tetrahydrate into a mixed solution consisting of 15.5 mL of absolute ethanol and 8.5 mL of deionized water, and stir ultrasonically for 5 h; then add 30 mg of dopamine hydrochloride and continue stirring for 10 min; then add 0.1 mL of NH 3 Commercially available ammonia water with a concentration marked as 25 wt% was stirred and reacted at 25°C for 6 hours; the reaction product was centrifuged, washed 3 times with absolute ethanol, and dried at 60°C. Put the dried product in a quartz tube furnace, under the protection of argon, heat it to 450°C for 1h, then raise the temperature to 750°C for 1.5h, and then cool it to room temperature to obtain MoO 2 Nanoparticles inlaid with carbon nanosheets to assemble tremella-shaped nanospheres.

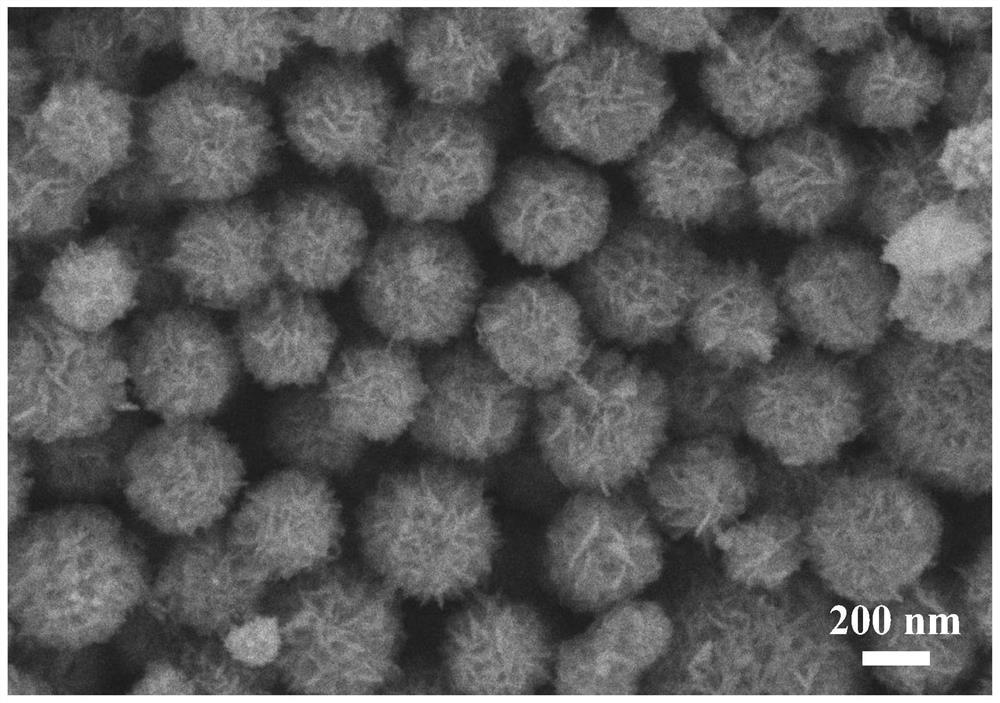

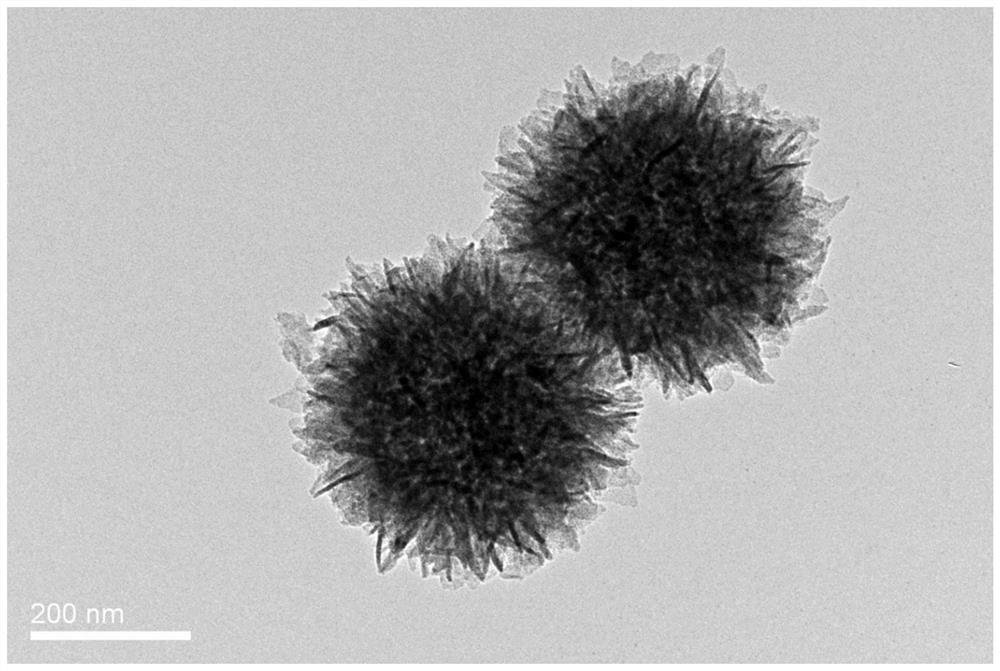

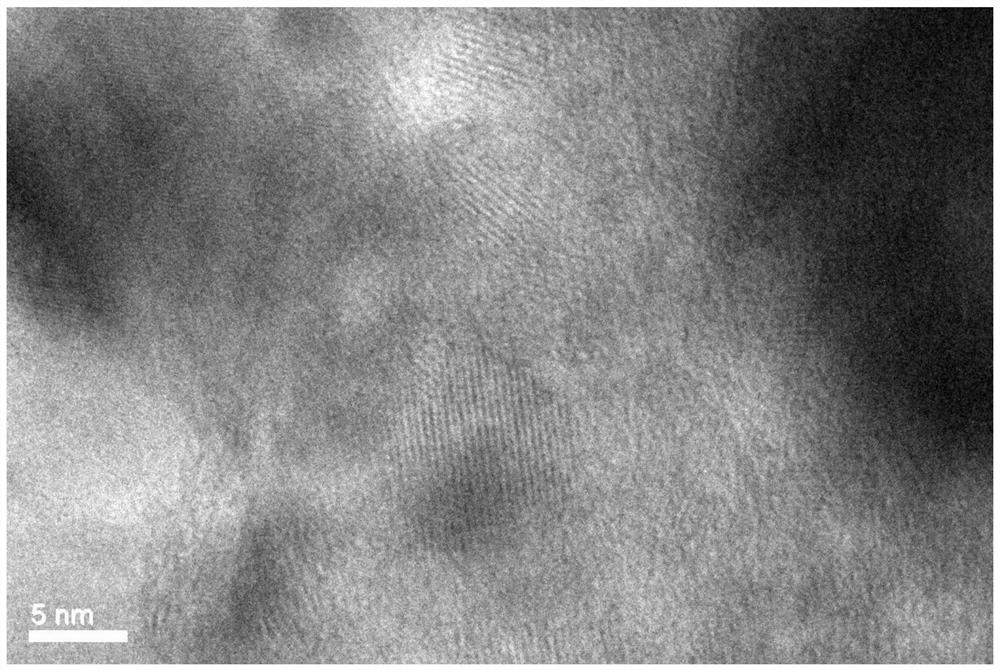

[0030] figure 1 is the synthetic MoO 2 The SEM photo of tremella-shaped nanospheres assembled with nanoparticle-embedded carbon nanosheets, it can be seen that the product is a uniform nanosphere with a di...

Embodiment 2

[0036] Add 30 mg of ammonium molybdate tetrahydrate into a mixed solution consisting of 15.5 mL of absolute ethanol and 8.5 mL of deionized water, and stir ultrasonically for 5 h; then add 30 mg of dopamine hydrochloride and continue stirring for 10 min; then add 0.2 mL of NH 3 Commercially available ammonia water with a concentration marked as 25 wt% was stirred and reacted at 25°C for 6 hours; the reaction product was centrifuged, washed 3 times with absolute ethanol, and dried at 60°C. Put the dried product in a quartz tube furnace, under the protection of argon, heat it to 450°C for 1h, then raise the temperature to 750°C for 1.5h, and then cool it to room temperature to obtain MoO 2 Nanoparticles inlaid with carbon nanosheets to assemble tremella-shaped nanospheres.

[0037] Product MoO 2 The microstructure of tremella-shaped nanospheres assembled with nanoparticle-embedded carbon nanosheets is the same as in Example 1, the main difference being that the carbon nanosheet...

Embodiment 3

[0040] Add 30 mg of ammonium molybdate tetrahydrate into a mixed solution consisting of 15.5 mL of absolute ethanol and 8.5 mL of deionized water, and stir ultrasonically for 5 h; then add 30 mg of dopamine hydrochloride and continue stirring for 10 min; then add 0.1 mL of NH 3 Commercially available ammonia water with a concentration of 25 wt% was stirred and reacted at 45°C for 6 hours; the reaction product was centrifuged, washed 3 times with absolute ethanol, and dried at 60°C. Put the dried product in a quartz tube furnace, under the protection of argon, heat it to 450°C for 1h, then raise the temperature to 750°C for 1.5h, and then cool it to room temperature to obtain MoO 2 Nanoparticles inlaid with carbon nanosheets to assemble tremella-shaped nanospheres.

[0041] Product MoO 2 The microstructure of tremella-shaped nanospheres assembled with nanoparticle-embedded carbon nanosheets is the same as that of Example 1, the main difference being that the tremella-shaped na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com