Carbon-cobalt-molybdenum double-metal phosphide composite material and preparation method thereof

A composite material and bimetal technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as poor stability of metal phosphides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

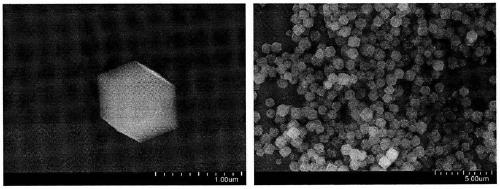

[0028] (1) Weigh 0.996gCo(NO 3 ) 2 ·6H 2 O and 1.312g 2-methylimidazole were dissolved in 100ml methanol respectively, and stirred for 10 minutes. After stirring and dissolving, the 2-methylimidazole solution was quickly poured into Co(NO 3 ) 2 In the solution, continue to stir for 10 minutes, stop stirring and then age at room temperature for 24 hours, then centrifuge the product, wash it with methanol for 3 times, and finally dry it in vacuum at 60°C for 8 hours. Blue-purple, rhombic dodecahedron in shape.

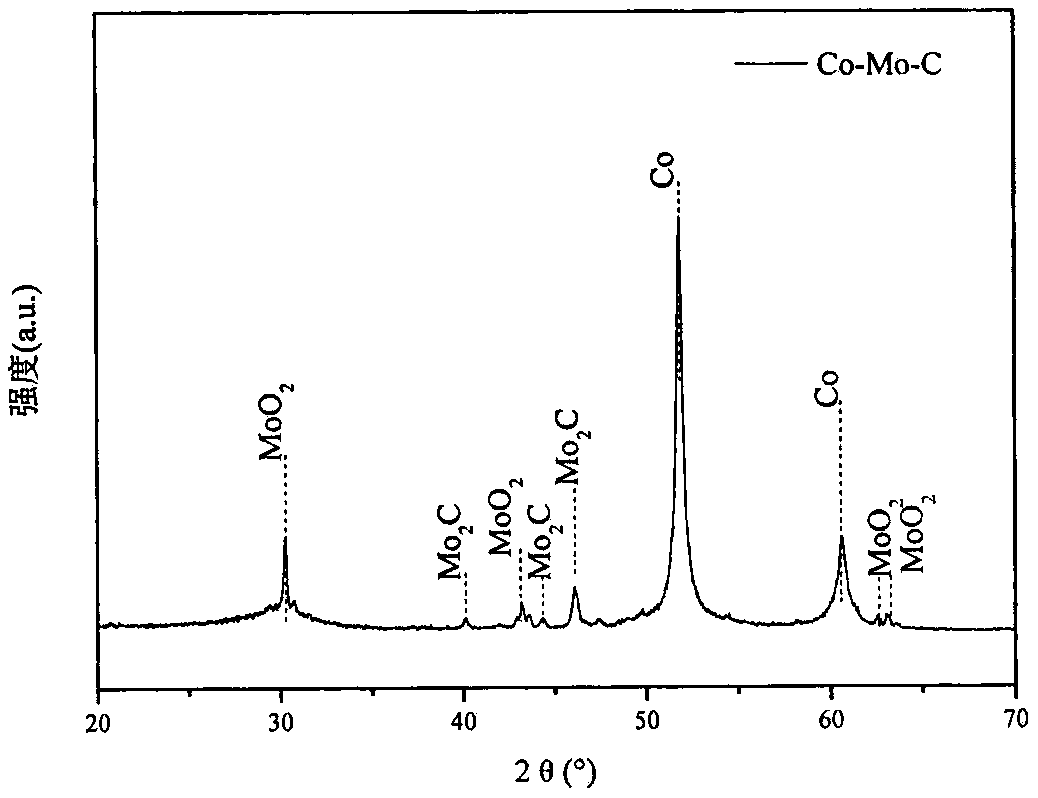

[0029] (2) 120mg MoO 3 Put 40mg of Co-based organic compound in a quartz boat and put it into a tubular resistance furnace, raise the temperature from room temperature to the target temperature of 800°C at a rate of 5°C / min in an argon atmosphere, and keep it constant for 2h, pass through MoO 3 Heating sublimation introduces Mo element into the dodecahedral porous carbon composite material Co-C with cobalt metal element, and prepares MoO containing 2 、Mo 2 Co-Mo-C...

Embodiment 2

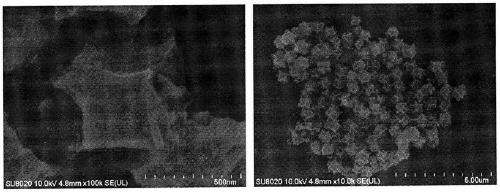

[0032] (1) Weigh 1g of Co(NO 3 ) 2 ·6H 2 O and 3g of 2-methylimidazole were respectively dissolved in 100ml of methanol and stirred for 10 minutes. After stirring and dissolving, the 2-methylimidazole solution was quickly poured into Co(NO 3 ) 2 In the solution, continue to stir for 20 minutes, stop stirring and then age at room temperature for 14 hours, then centrifuge the product, wash it with methanol for 3 times, and finally dry it in vacuum at 60°C for 12 hours. Blue-purple, rhombic dodecahedron in shape.

[0033] (2) 150mg MoO 3 Put 60mg of Co-based organic compound in a quartz boat and put it into a tubular resistance furnace, raise the temperature from room temperature to the target temperature of 750°C at a rate of 5°C / min in an argon atmosphere, and keep it constant for 4h, pass through MoO 3 Heating sublimation introduces Mo element into the dodecahedral porous carbon composite material Co-C with cobalt metal element, and prepares MoO containing 2 、Mo 2 Co-Mo-C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com