An automatic assembly and packaging production line for an electric iron and an automatic assembly process

An automatic production line and electric iron technology, applied in the direction of automatic packaging control, packaging, assembly machines, etc., can solve the problems of low efficiency, difficult consistency of product quality, difficult market demand, etc., achieve good compatibility and realize the goal of automatic assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

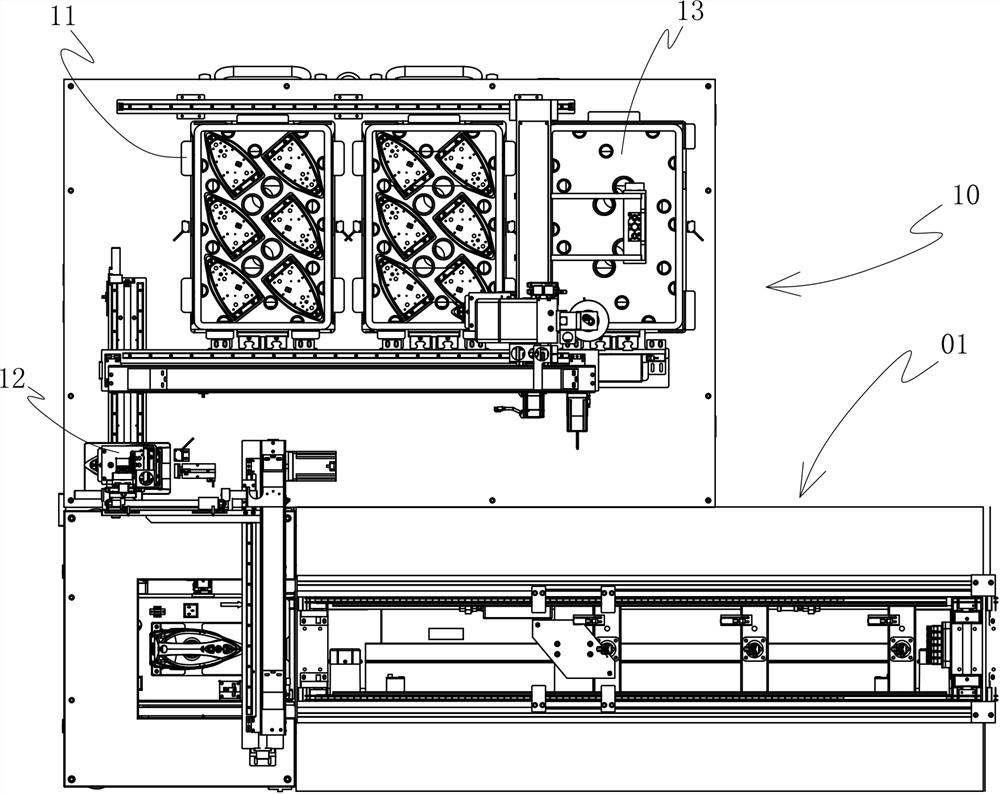

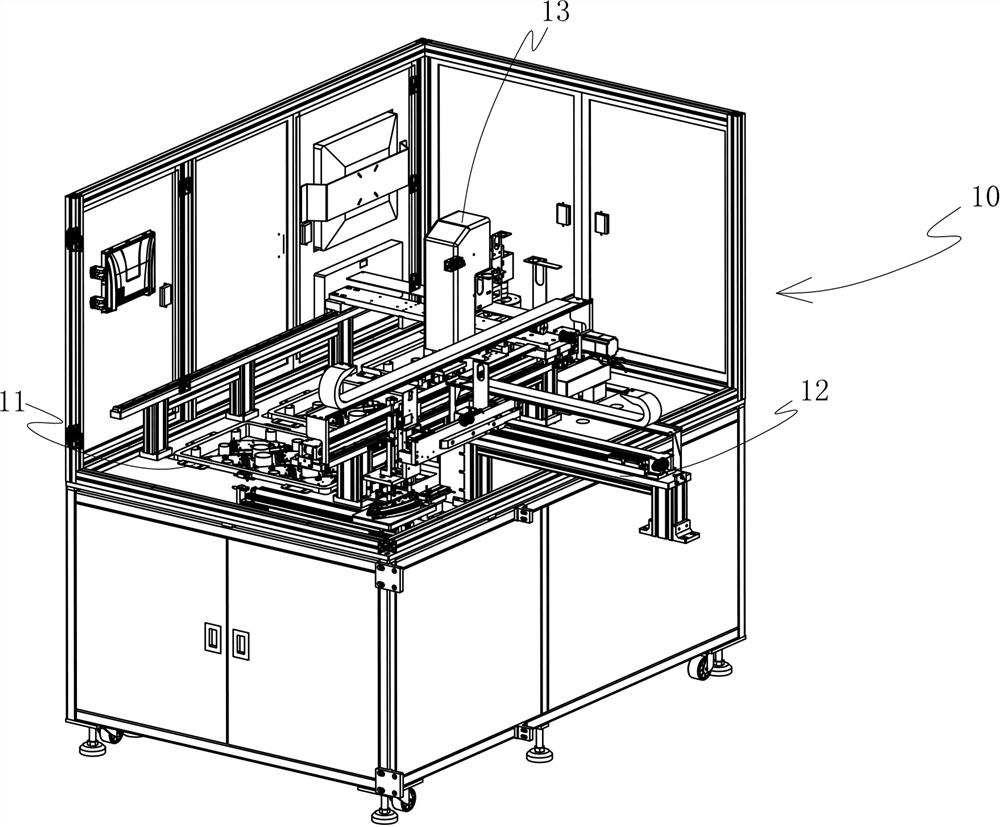

[0051] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0052] Please refer to Figure 1-15 , the embodiment of the present invention includes:

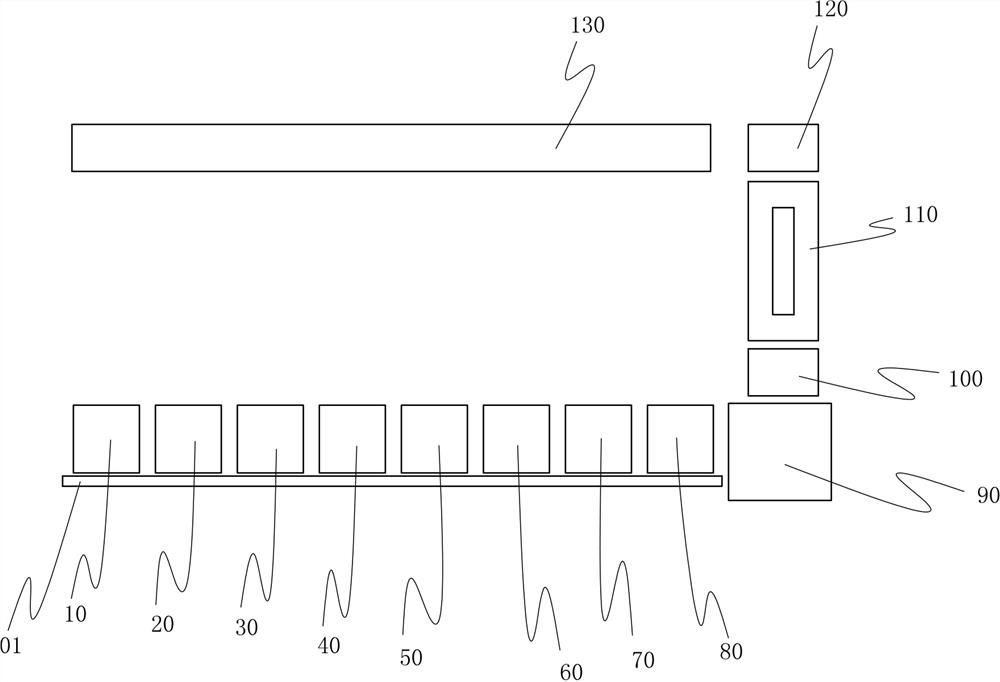

[0053] An automatic assembly and packaging production line for electric irons, including a control system, an assembly line for assembling electric irons controlled by the control system and arranged sequentially, and a detection line for testing the performance of electric irons, wherein the control system is specifically a PLC control system, which The internal storage program can execute user-oriented instructions such as logic operation, sequence control, timing, counting and arithmetic operations.

[0054] The assembly line includes a conveying line 01 electrically connected to the control system, a soleplate feeder 10 arranged on the conveying line 01 and arranged side by si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com