Ultra-early strength high-performance concrete and preparation method thereof

A high-performance concrete and high-efficiency water-reducing agent technology, applied in the field of building materials, can solve the problems of complex molding and maintenance processes, materials that cannot be applied on a large scale, and low 7d strength, so as to improve work performance and mechanical properties, improve The problem of brittleness, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

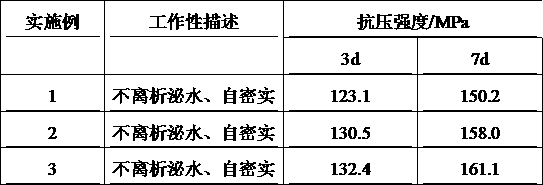

[0032] Embodiment 1: A kind of ultra-early-strength high-performance concrete and preparation method thereof, in parts by weight, comprising: 708 parts of cement, 472 parts of composite mineral admixtures, 189 parts of water, 1180 parts of composite aggregate, polycarboxylic acid 47.2 parts of high-efficiency water reducer, 0.20 parts of defoamer, and 157 parts of steel fiber; the composite mineral admixture is composed of 177 parts of fine beads, 59 parts of metakaolin, and 236 parts of silica fume; the composite aggregate It is composed of 543 parts of Chinese ISO standard sand (intermediate sand), 255 parts of 5-10mm basalt gravel, and 382 parts of 10-16mm basalt gravel.

[0033] The preparation method of the above-mentioned ultra-strong high-performance concrete comprises the following steps: (1) fully wetting the mixer and the container for containing the concrete with cement mortar having the same water-binder ratio as the ultra-strong high-performance concrete; (2) weigh...

Embodiment 3

[0035] Embodiment 3: A kind of ultra-early-strength high-performance concrete and its preparation method, including: 743 parts of cement, 413 parts of composite mineral admixture, 177 parts of water, 1180 parts of composite aggregate, polycarboxylic acid 48 parts of high-efficiency water reducer, 0.20 parts of defoamer, and 157 parts of steel fiber; the composite mineral admixture is composed of 165 parts of fine beads, 59 parts of metakaolin, and 212.4 parts of silica fume; the composite aggregate It is composed of 514 parts of Chinese ISO standard sand (intermediate sand), 266 parts of 5-10mm basalt gravel, and 400 parts of 10-16mm basalt gravel. After taking the materials, the ultra-strong high-performance concrete was produced according to the process described in Example 1. After testing, the compressive strength of the standard cultured 7d was 161.1MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com