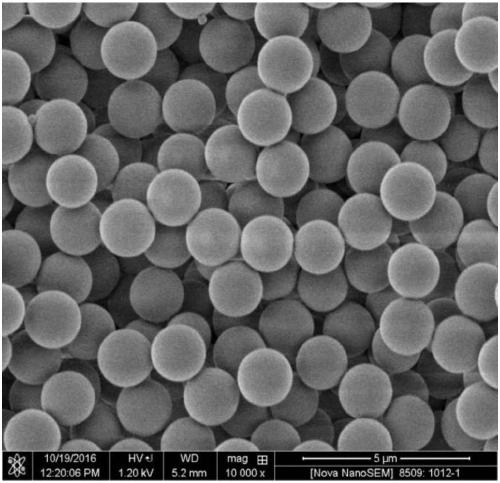

Anion-cation composite core-shell structure polymer microsphere and preparation method thereof

A technology of polymers and microspheres, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of insufficient migration ability of polymer profile control agents, and achieve good depth profile control effect and good technical effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

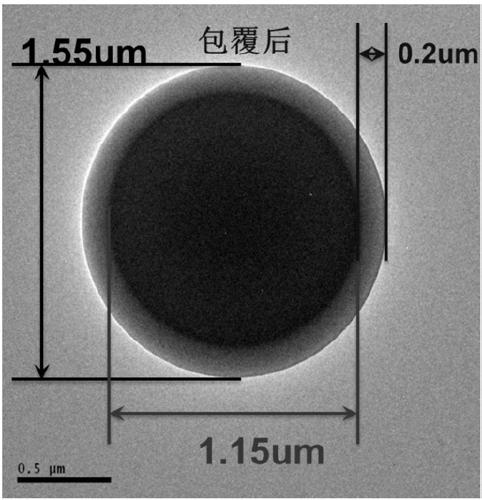

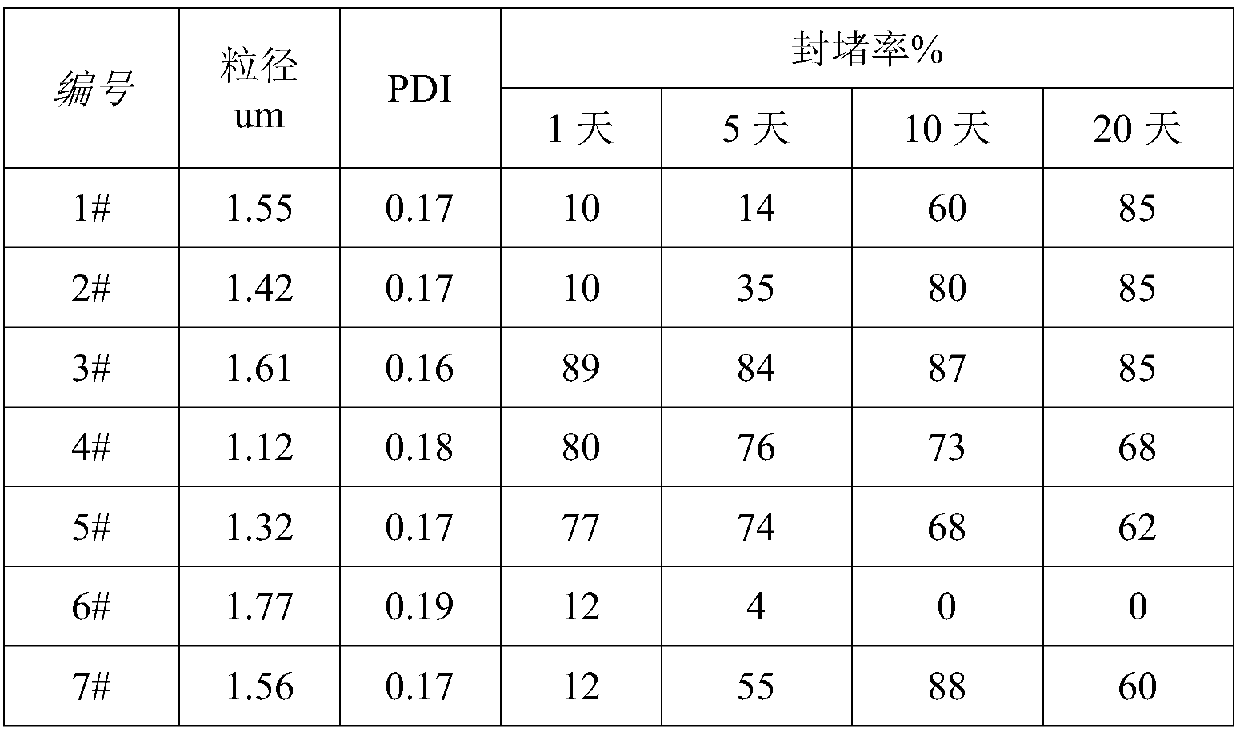

Embodiment 1

[0055] Dissolve 40 parts of acrylamide, 15 parts of methacryloxyethyltrimethylammonium chloride, 0.02 parts of disodium edetate, 1 part of polyethylene glycol 20000, and 1 part of tert-butylacrylamide in 60 Part water and 200 parts ethanol in the mixed solvent configuration and stir evenly. The solution was added to the reaction kettle, the stirring rate was 200r / min, the inert gas was passed through, and the temperature of the water bath was 50°C. After continuous stirring for 30min, the composite initiator system (22mg ammonium persulfate, 20mg sodium bisulfite, 15mg tetramethylethylenediamine, 30mg azobisisobutyl ether hydrochloride) was dissolved in 5g ethanol and water at a ratio of 7 : 3 mixed solvents, dropwise into the reaction kettle. The reaction was continued for 1 hour.

[0056] Dissolve 40 parts of acrylamide, 10 parts of 2-acrylamido-dimethylpropanesulfonic acid, 0.02 parts of disodium edetate, 1 part of polyethylene glycol 20000, and 1 part of tert-butylacryla...

Embodiment 2

[0061] Dissolve 40 parts of acrylamide, 15 parts of methacryloxyethyltrimethylammonium chloride, 0.02 parts of disodium edetate, 1 part of polyethylene glycol 20000, and 1 part of tert-butylacrylamide in 60 Part water and 200 parts ethanol in the mixed solvent configuration and stir evenly. The solution was added to the reaction kettle, the stirring rate was 200r / min, the inert gas was passed through, and the temperature of the water bath was 50°C. After continuous stirring for 30min, the composite initiator system (22mg ammonium persulfate, 20mg sodium bisulfite, 15mg tetramethylethylenediamine, 30mg azobisisobutyl ether hydrochloride) was dissolved in 5g ethanol and water at a ratio of 7 : 3 mixed solvents, dropwise into the reaction kettle. The reaction was continued for 1 hour.

[0062] Dissolve 20 parts of acrylamide, 5 parts of 2-acrylamido-dimethylpropanesulfonic acid, 0.01 parts of disodium edetate, 0.5 parts of polyethylene glycol 20000, 0.5 parts of tert-butylacryl...

Embodiment 3

[0067] Dissolve 40 parts of acrylamide, 10 parts of 2-acrylamido-dimethylpropanesulfonic acid, 0.02 parts of disodium edetate, 1 part of polyethylene glycol 20000, and 1 part of tert-butylacrylamide in 60 parts Stir evenly in the mixed solvent of water and 200 parts of ethanol configuration. The solution was added to the reaction kettle, the stirring rate was 200r / min, the inert gas was passed through, and the temperature of the water bath was 50°C. After continuous stirring for 30min, the composite initiator system (22mg ammonium persulfate, 20mg sodium bisulfite, 15mg tetramethylethylenediamine, 30mg azobisisobutyl ether hydrochloride) was dissolved in 5g ethanol and water at a ratio of 7 : 3 mixed solvents, dropwise into the reaction kettle. The reaction was continued for 1 hour.

[0068] Dissolve 40 parts of acrylamide, 15 parts of methacryloxyethyltrimethylammonium chloride, 0.02 parts of disodium edetate, 1 part of polyethylene glycol 20000, and 1 part of tert-butylacr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com