Applications of sulfur-containing polyimide resin as nickel adsorbent

A technology of sulfur-containing polyimide resin and sulfur-polyimide resin, which is applied in the application field of sulfur-containing polyimide resin as a nickel adsorbent, and can solve the problems of low temperature resistance, narrow use range, and poor regeneration ability, etc. problems, to achieve the effect of good thermal stability, convenient operation and simple adsorption process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

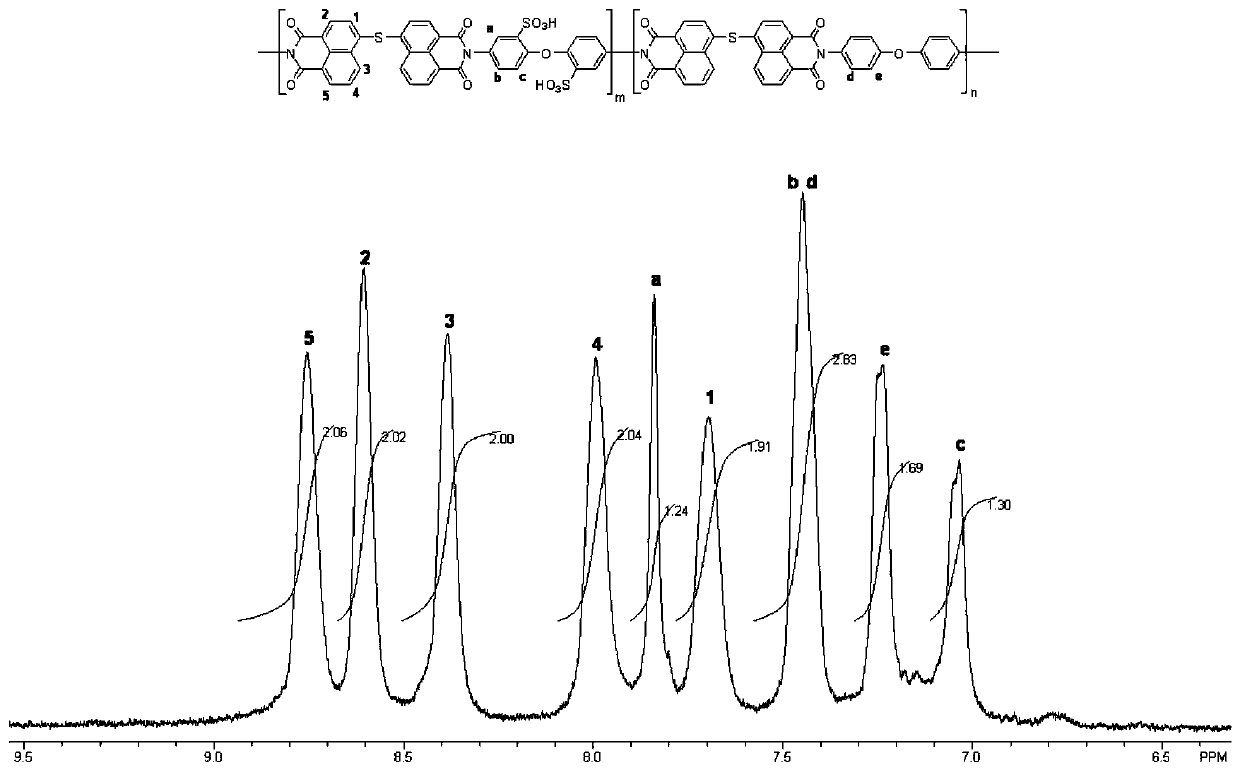

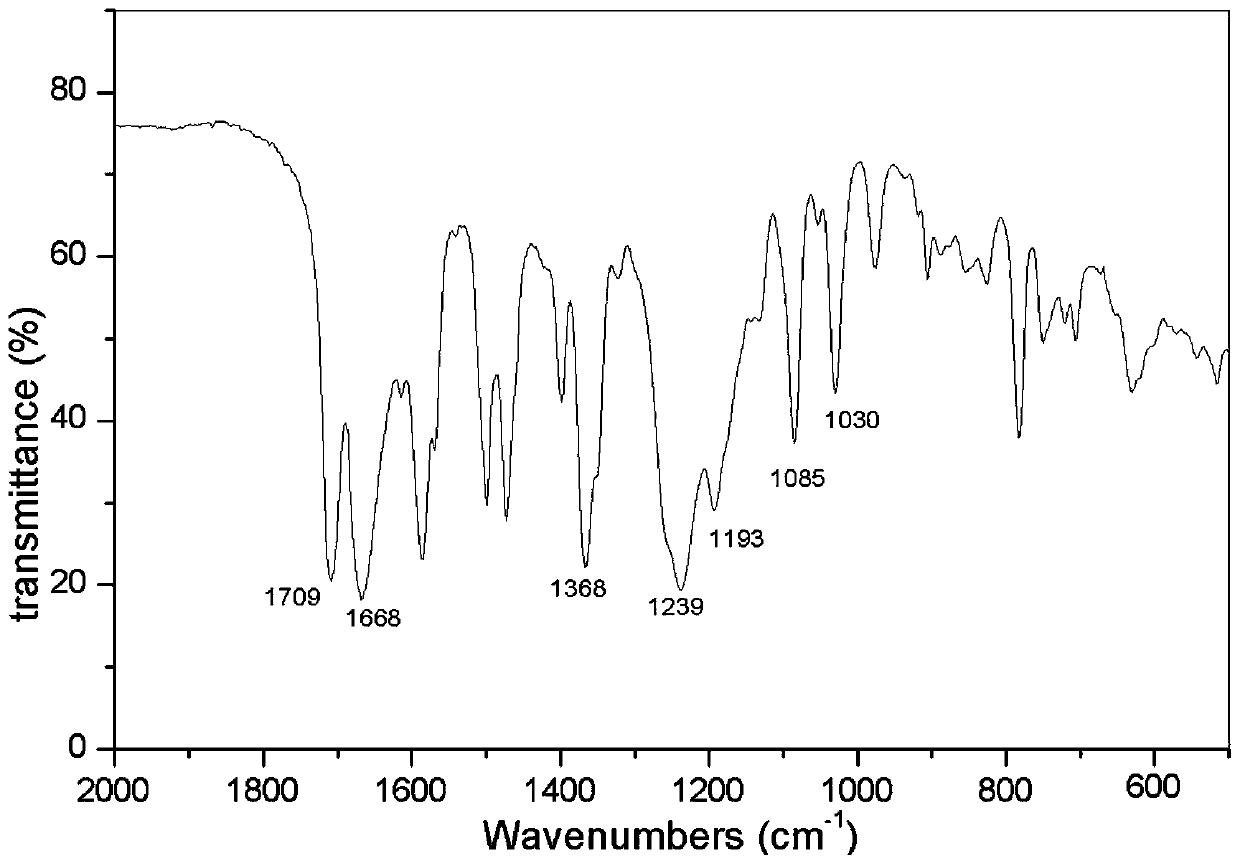

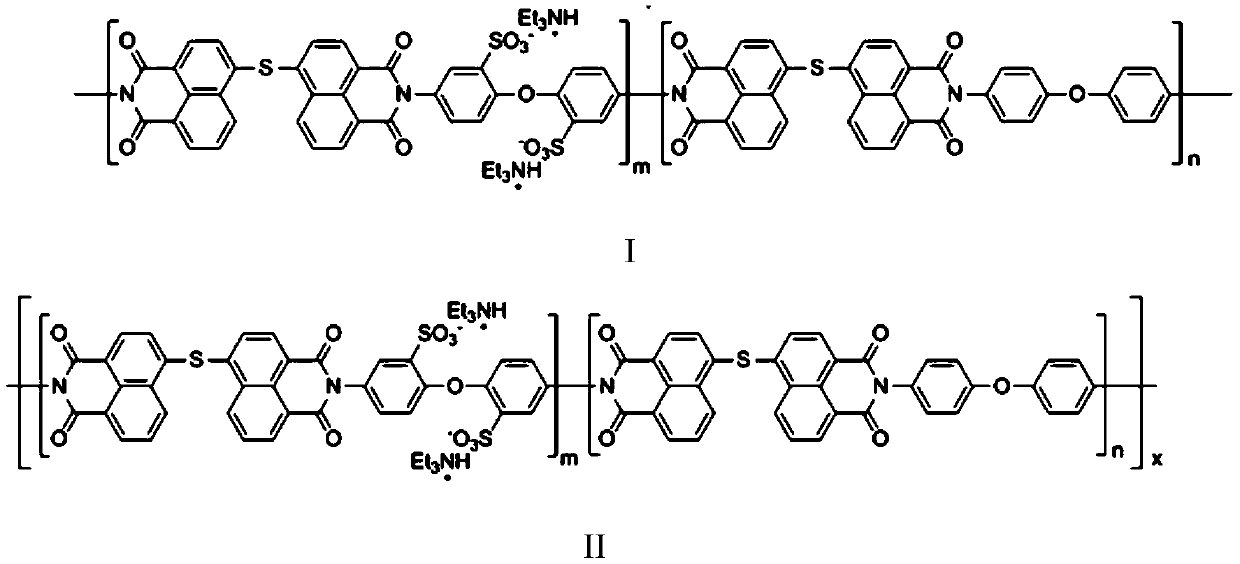

[0048] The sulfur-containing diamine monomer 2,2'-bis(sulfonic acid)-4,4'-diaminodiphenyl ether (ODADS) and the sulfur-free diamine monomer 4,4'-diaminodiphenyl ether The molar ratio of (ODA) was set to 6:4 for the feeding reaction, and the reaction was carried out according to the preparation method of random sulfur-containing polyimide to obtain random sulfur-containing polyimide resin particles.

[0049] Add 2,2'-bis(sulfonic acid)-4,4'-diaminodiphenyl ether ODADS (0.6524g, 1.81mmol), triethylamine (0.5390g, 5.33mmol) and 8mL m-cresol, stirred to dissolve ODADS completely, then added 4,4'-diaminodiphenyl ether ODA (0.2417g, 1.21mmol), thioether naphthalene dianhydride SBNTA (1.2866g, 3.02mmol) and Benzoic acid (0.5522g, 4.53mmol). The mixture was stirred at room temperature for 30 minutes, then warmed to 80°C for 4h and 180°C for 18h. When the mixture was cooled to 80°C, it was poured into 500 mL of acetone to obtain a fibrous polymer. After washing once with acetone, ex...

Embodiment 2

[0057] The molar ratio of sulfur-containing diamine monomer and sulfur-free diamine monomer is set to 6:4 for feeding reaction, and the reaction is carried out according to the preparation method of block type sulfur-containing polyimide resin to obtain block type Sulfur-containing polyimide resin particles.

[0058] Add sulfonated diamine ODADS (0.6618g, 1.84mmol), triethylamine (0.4467g, 4.41mmol) and 8mL m-cresol into a No. Ether naphthalene dianhydride SBNTA (0.7640 g, 1.79 mmol) and benzoic acid (0.3274 g, 2.68 mmol). The mixture was stirred at room temperature for 30 minutes, then heated to 80° C. for 4 hours, and 180° C. for 18 hours to obtain an amine-terminated polyimide oligomer. Add the remaining naphthalene dianhydride SBNTA (0.5420g, 1.27mmol) and 8mL m-cresol into another No. 2 oblique three-neck flask protected by nitrogen, stir and dissolve, then add unsulfonated diamine ODA (0.2454g, 1.23mmol ), benzoic acid (0.2324g, 1.91mmol), reacted at 180°C for 18h. Wh...

Embodiment 3

[0064] The molar ratio of the sulfur-containing diamine monomer and the sulfur-free diamine monomer is set to 6:4 for the feeding reaction, and the reaction is carried out according to the preparation method of the random sulfur-containing polyimide of Example 1 to obtain Random sulfur-containing polyimide resin particles.

[0065] Add copper ions and cadmium ions to the nickel solution to prepare a mixed solution containing 2mg / L nickel ions, 1mg / L copper ions and 1mg / L cadmium ions.

[0066] Get 1.0g of the random type sulfur-containing polyimide resin particles prepared above, add to 50mL the mixed solution containing 2mg / L nickel ion, 1mg / L copper ion and 1mg / L cadmium ion, put The shaker was shaken for 30 minutes, and the supernatant was taken by centrifugation. The concentration of nickel ions in the supernatant was measured to be 0.033mg / L, the removal rate of nickel ions was 98.4%, and the concentrations of copper ions and cadmium ions remained basically unchanged, pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com