Application of sulfur-containing polyimide resin as rare earth element adsorbent

A technology of sulfur-containing polyimide resin and sulfur-polyimide resin, which is applied in the field of sulfur-containing polyimide resin, can solve the problems of time-consuming and energy-consuming, complex steps, difficult rare earth mining, etc., and achieve stable chemical and physical properties, simple regeneration process, and simple adsorption process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

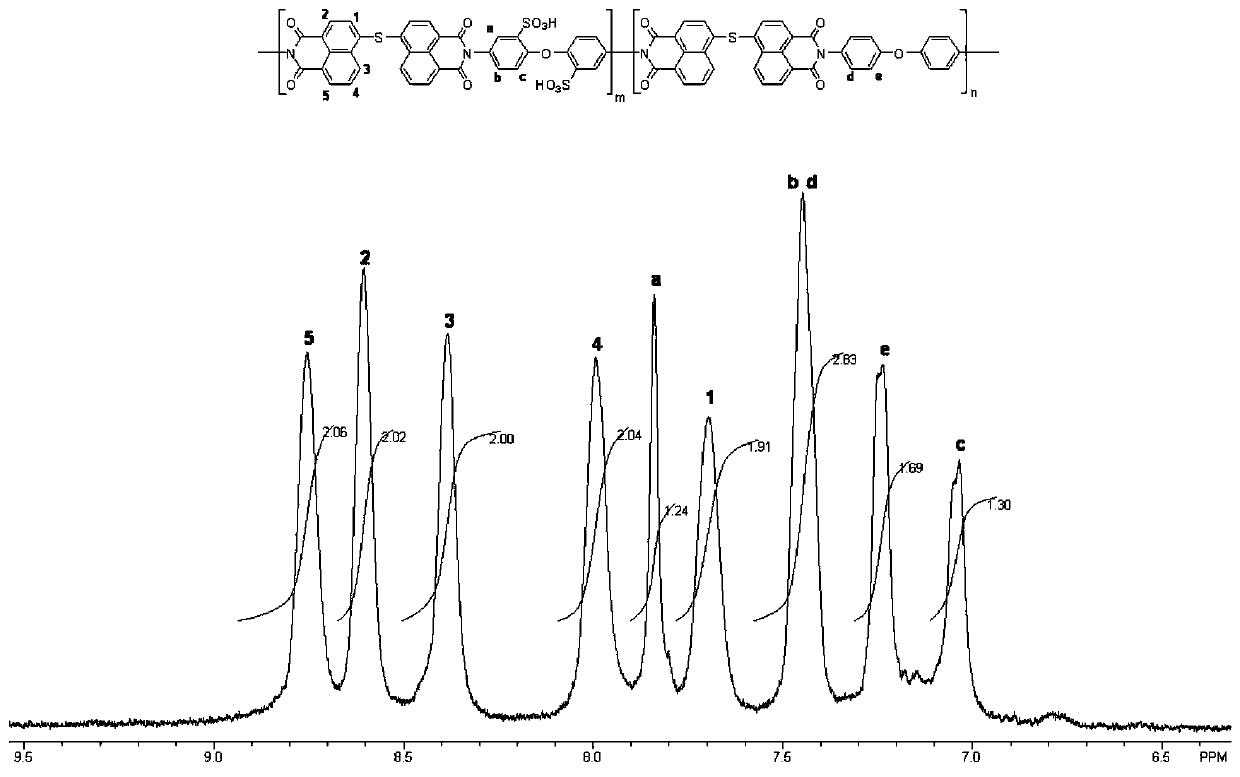

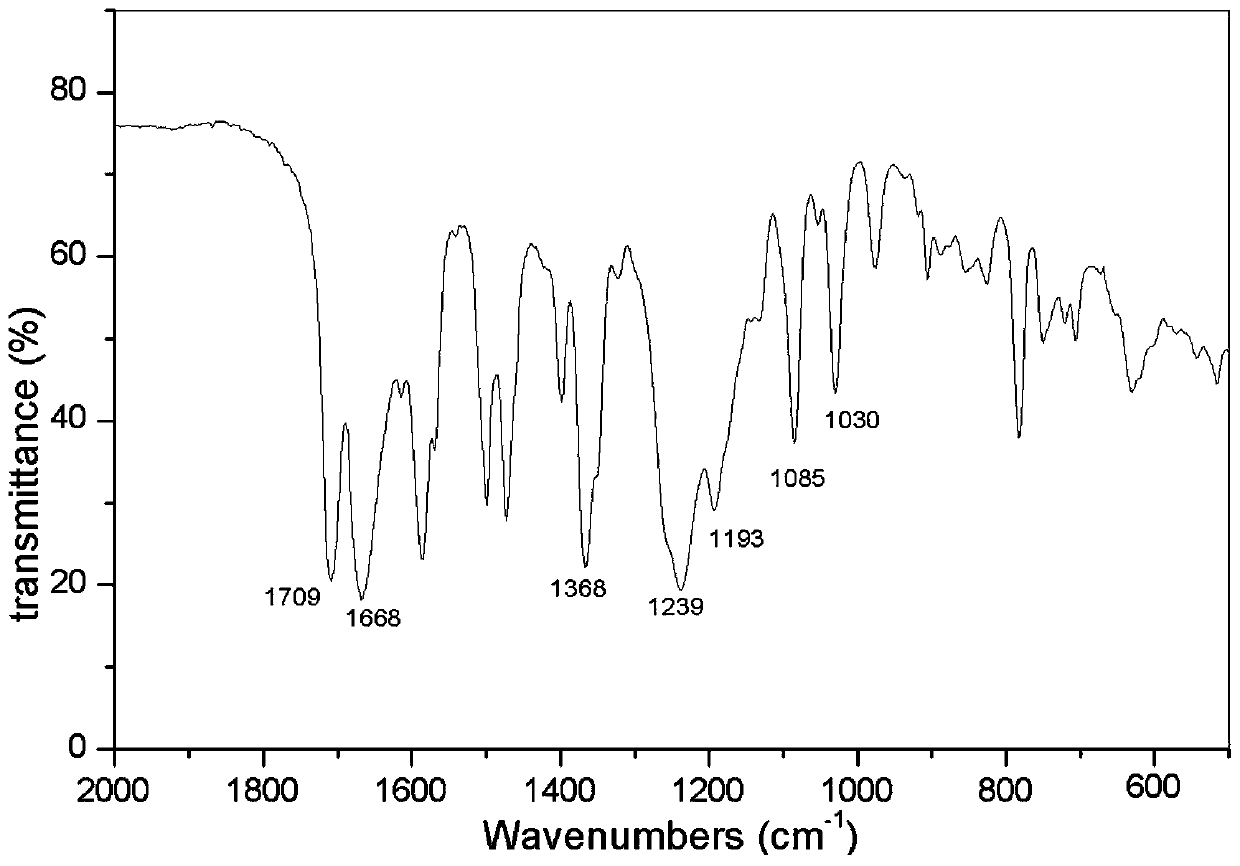

[0049] The sulfur-containing diamine monomer 2,2'-bis(sulfonic acid)-4,4'-diaminodiphenyl ether (ODADS) and the sulfur-free diamine monomer 4,4'-diaminodiphenyl ether The molar ratio of (ODA) was set to 6:4 for the feeding reaction, and the reaction was carried out according to the preparation method of random sulfur-containing polyimide to obtain random sulfur-containing polyimide resin particles.

[0050] Add 2,2'-bis(sulfonic acid)-4,4'-diaminodiphenyl ether ODADS (0.6524g, 1.81mmol), triethylamine (0.5390g, 5.33mmol) and 8mL m-cresol, stirred to dissolve ODADS completely, then added 4,4'-diaminodiphenyl ether ODA (0.2417g, 1.21mmol), thioether naphthalene dianhydride SBNTA (1.2866g, 3.02mmol) and Benzoic acid (0.5522g, 4.53mmol). The mixture was stirred at room temperature for 30 minutes, then warmed to 80°C for 4h and 180°C for 18h. When the mixture was cooled to 80°C, it was poured into 500 mL of acetone to obtain a fibrous polymer. After washing once with acetone, ex...

Embodiment 2

[0059] Embodiment 2 Potassium, calcium, sodium, magnesium, aluminum, zinc, iron, tin, lead interference experiment

[0060] The molar ratio of the sulfur-containing diamine monomer and the sulfur-free diamine monomer is set to 6:4 for the feeding reaction, and the reaction is carried out according to the preparation method of the random sulfur-containing polyimide of Example 1 to obtain Random sulfur-containing polyimide resin particles.

[0061] Add potassium ions, calcium ions, sodium ions, magnesium ions, aluminum ions, zinc ions, iron ions, tin ions and lead at a concentration of 0.5 mg / L to the mixed solution with the contents of 16 rare earth elements at 0.2 mg / L. Ions, prepared as a multi-element interference mixed solution.

[0062] Take 1.0 g of the above-mentioned random sulfur-containing polyimide resin particles, add it to 50 mL of the above-mentioned multi-element interference mixed solution, put it in a shaker and shake it for 30 minutes, centrifuge to take the ...

Embodiment 3

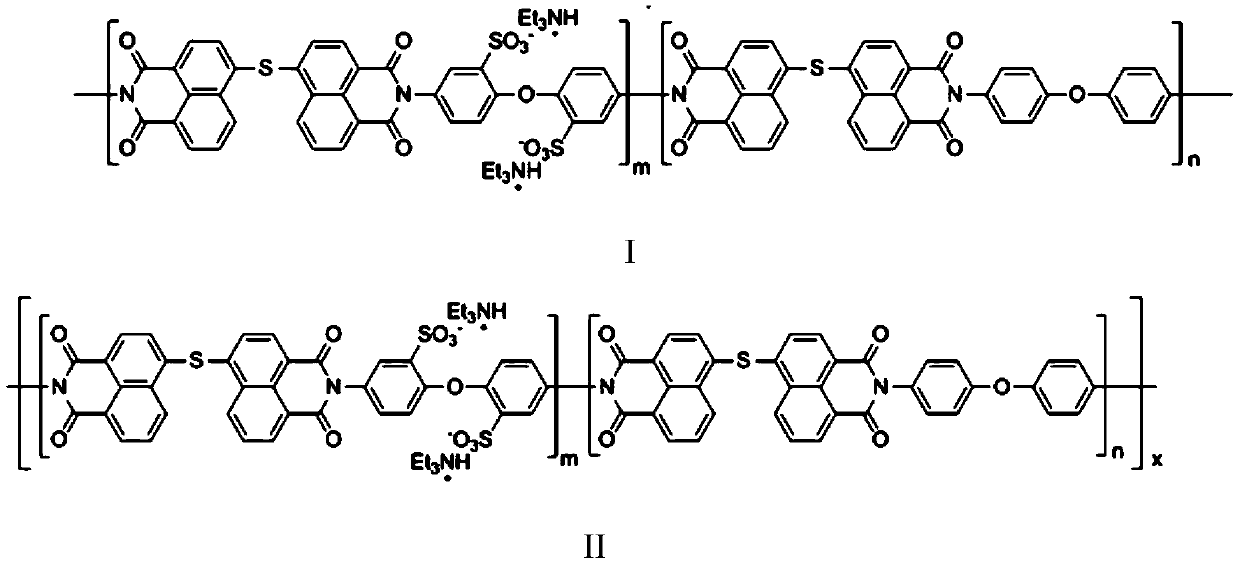

[0066] The molar ratio of sulfur-containing diamine monomer and sulfur-free diamine monomer is set to 6:4 for feeding reaction, and the reaction is carried out according to the preparation method of block type sulfur-containing polyimide resin to obtain block type Sulfur-containing polyimide resin particles.

[0067] Add sulfonated diamine ODADS (0.6618g, 1.84mmol), triethylamine (0.4467g, 4.41mmol) and 8mL m-cresol into a No. Ether naphthalene dianhydride SBNTA (0.7640 g, 1.79 mmol) and benzoic acid (0.3274 g, 2.68 mmol). The mixture was stirred at room temperature for 30 minutes, then heated to 80° C. for 4 hours, and 180° C. for 18 hours to obtain an amine-terminated polyimide oligomer. Add the remaining naphthalene dianhydride SBNTA (0.5420g, 1.27mmol) and 8mL m-cresol into another No. 2 oblique three-neck flask protected by nitrogen, stir and dissolve, then add unsulfonated diamine ODA (0.2454g, 1.23mmol ), benzoic acid (0.2324g, 1.91mmol), reacted at 180°C for 18h. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com