Oil-containing sewage degradation compound bacterium and preparation method thereof

A technology of compound bacteria and sewage, applied in the fields of biochemical equipment and methods, chemical instruments and methods, biological water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

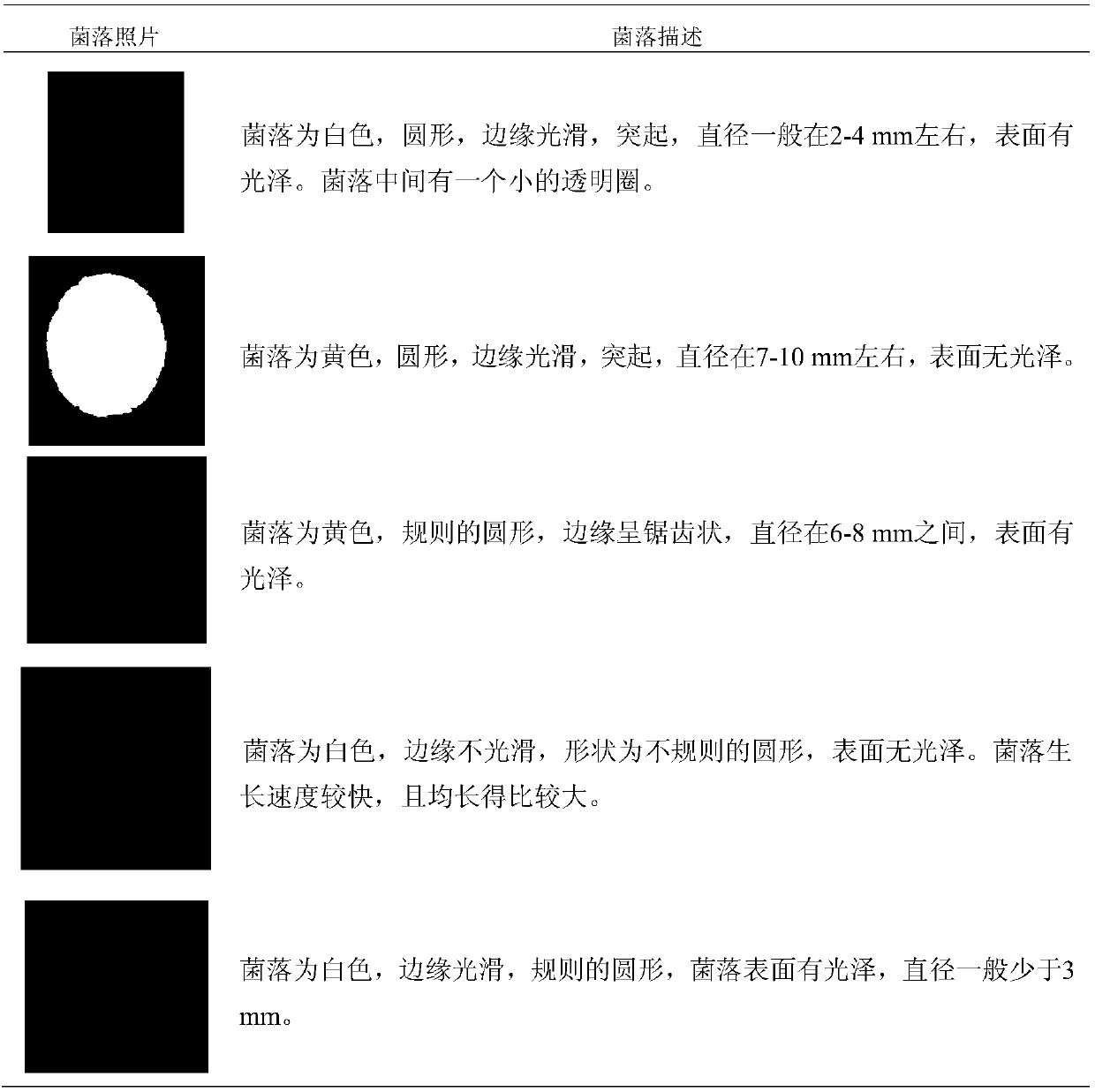

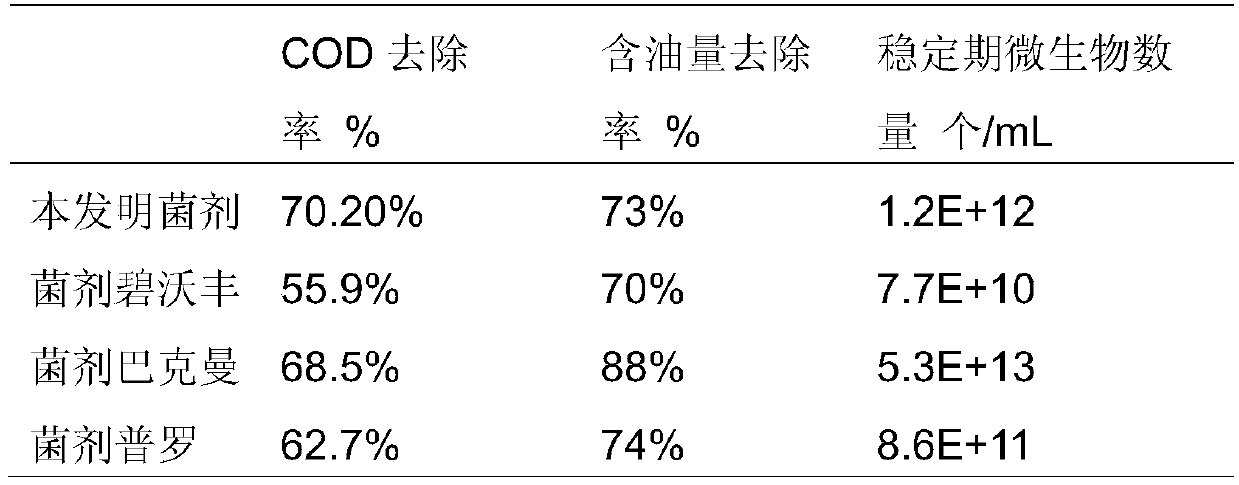

[0022] Taking the sewage treatment experimental base of Daqing Water Affairs Company as an example, to evaluate the effect of treating oily sewage, the influent water is taken from the Changyuan Biochemical Station of the No. 1 Oil Production Plant, and the pH value of the influent water is 8.5. After research, the pilot process was determined to be catalytic air flotation-reaction precipitation-contact oxidation-sand filtration. The processing capacity of the whole set of equipment is 1m 3 / h. Activate the strains in LB medium at 37°C for 48 hours, count the total number of colonies, dilute each strain to the same order of magnitude with sterile saline, and prepare bacterial suspensions with 1% of the amount of treated sewage Proportional dosing, in the traditional contact oxidation tank, place fillers, and add bacteria and nutrients in the early stage. Carry out pre-hanging film-hanging film-acclimation, and measure the water in and out of this section. Through a period o...

Embodiment 2

[0024] The 106-station pilot test of the No. 1 Oil Production Plant was used to evaluate the effect of treating oily sewage, and the pH value of the influent water was 9.5. The pilot process is raw water—dissolved air flotation—biological contact oxidation—precipitation—two-stage filtration. The processing capacity is 2m 3 / h, the raw water is incoming water from 106 stations; only for biological bacteria agents, in the contact oxidation tank, place fillers, add bacteria agents in the early stage, the activation and addition of bacteria agents are the same as in Example 1, and carry out pre-film-hang-film-acclimation , to measure the water in and out of this section, and through a period of data collection, it can be seen that the effect of the microbial agent is relatively stable. On the 31st-90th day of the pilot test, the treatment capacity of the flowing oily sewage is 2m 3 / h. At this stage, no additional substances were added. It can be seen that the trend of change i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com