Interface treatment method for reducing silicon and transition metal sulfide semiconductor schottky barrier

A technology of transition metal and Schottky potential, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of interface state Fermi pinning and high contact Schottky barrier, and achieve low Schottky Effect of base barrier, low ohmic contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

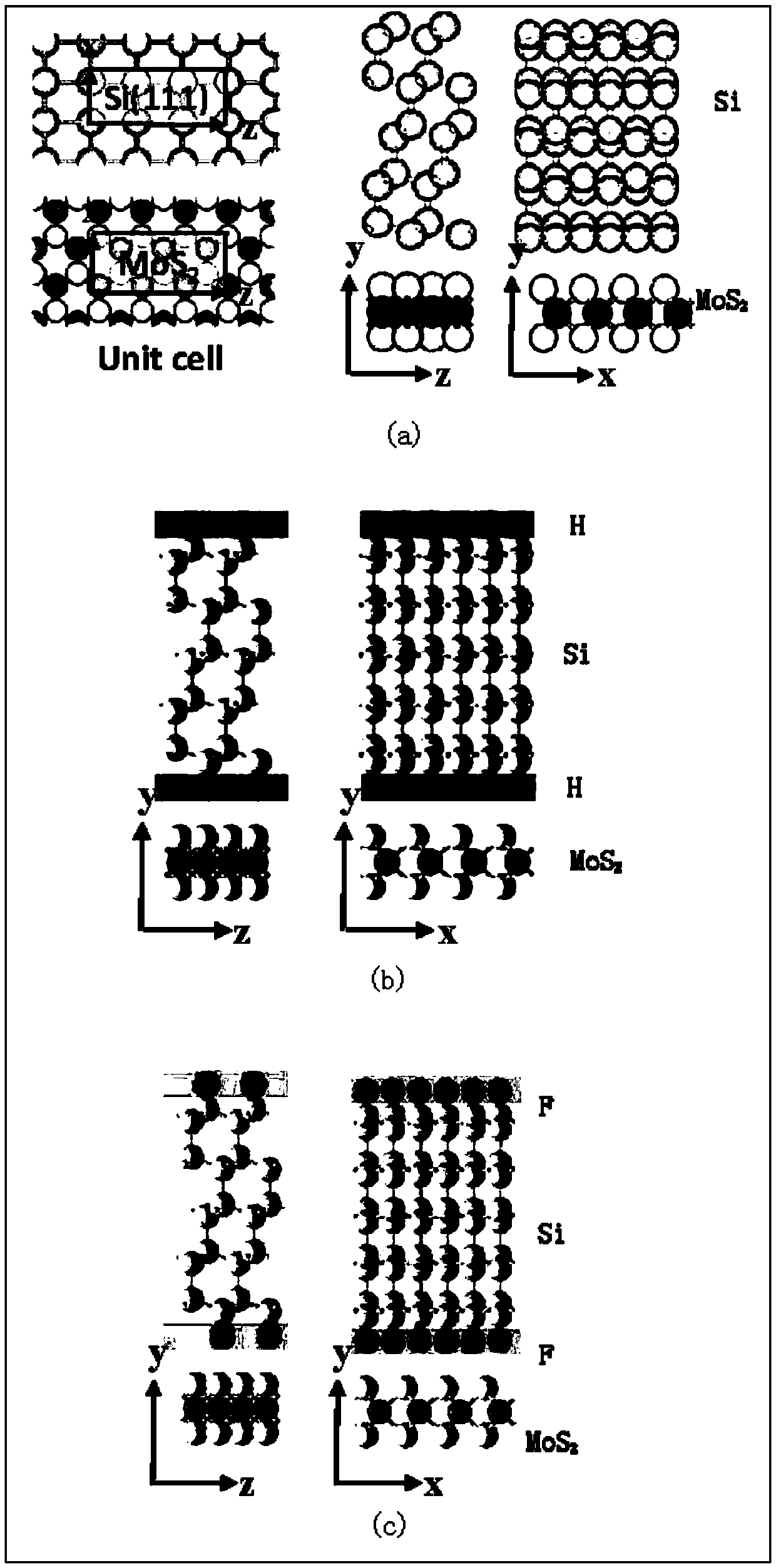

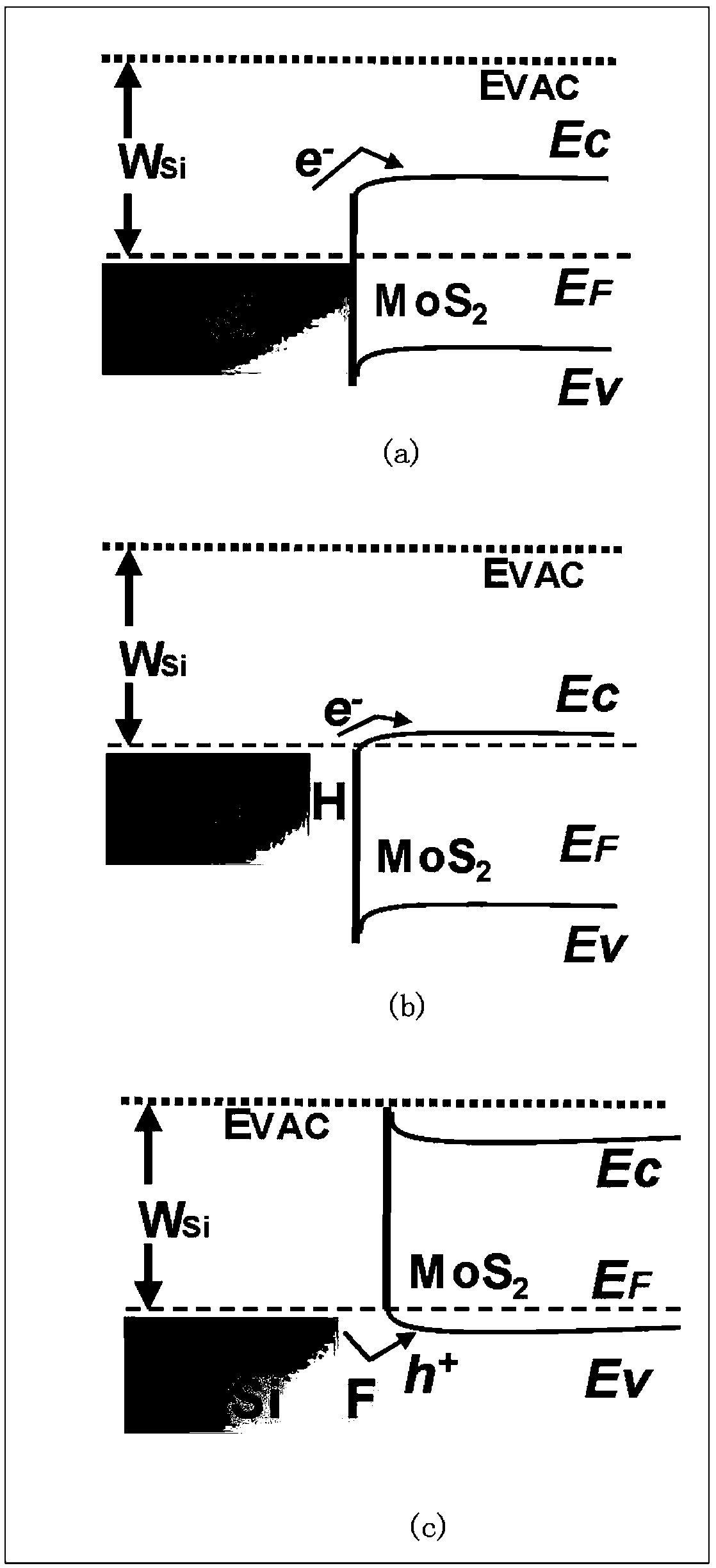

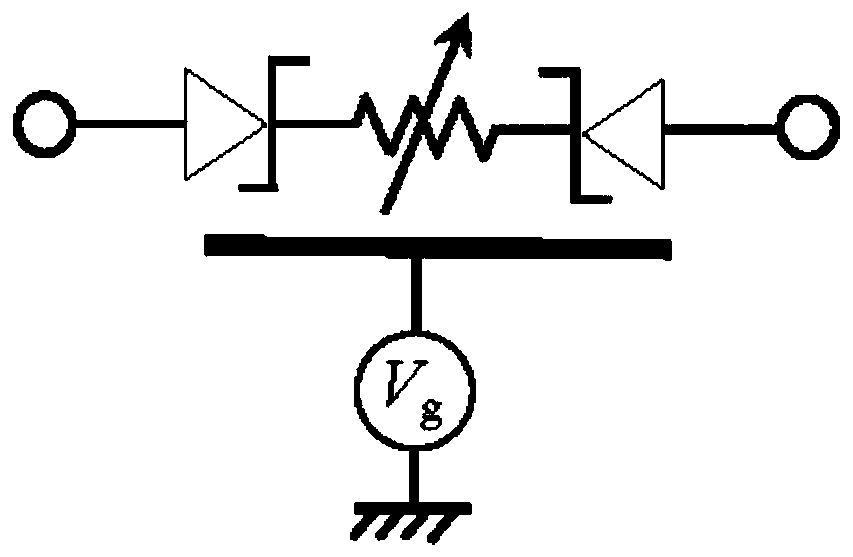

[0026] The method of the present invention to reduce the Schottky barrier of silicon and transition metal sulfide semiconductors is to passivate both the upper and lower surfaces of Si or only passivate the Si side close to the semiconductor surface, that is, through hydrogen or fluorine Surface passivation treatment is a well-known process for forming unsaturated Si bonds on the surface. After the surface of Si is passivated with hydrogen or fluorine, it can be in surface contact with both ends of the transition metal sulfide to form a NIN type Schottky field effect transistor and a PIP type Schottky field effect transistor respectively. Si-MoS passivated by hydrogen 2 system, the Si should be electronically doped. Si-MoS passivated by fluorine 2 system, hole doping is required for Si.

[0027] The method of the present invention will be further described in detail below by describing specific embodiments in conjunction with the accompanying drawings.

[0028] The interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com