Single-walled carbon nanotube transparent electrothermal film and preparation method thereof

A technology of single-walled carbon nanotubes and electric heating film, which is applied in the direction of carbon nanotubes, nanocarbons, electric heating devices, etc., to achieve the effects of simple operation, improved conductivity, and excellent heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

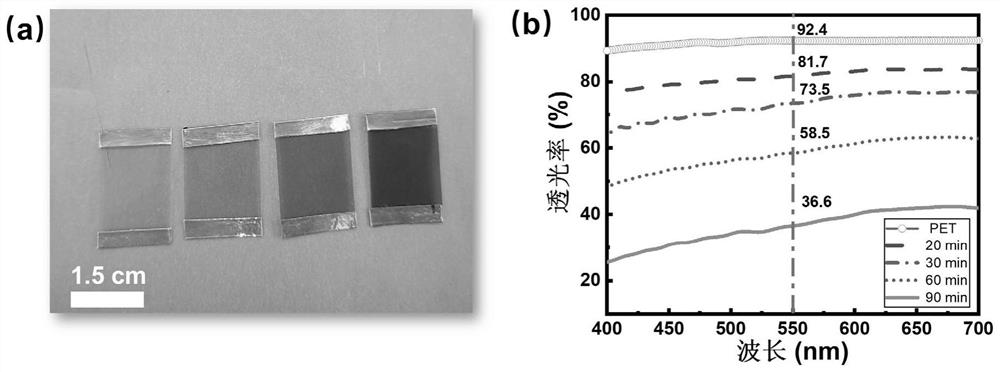

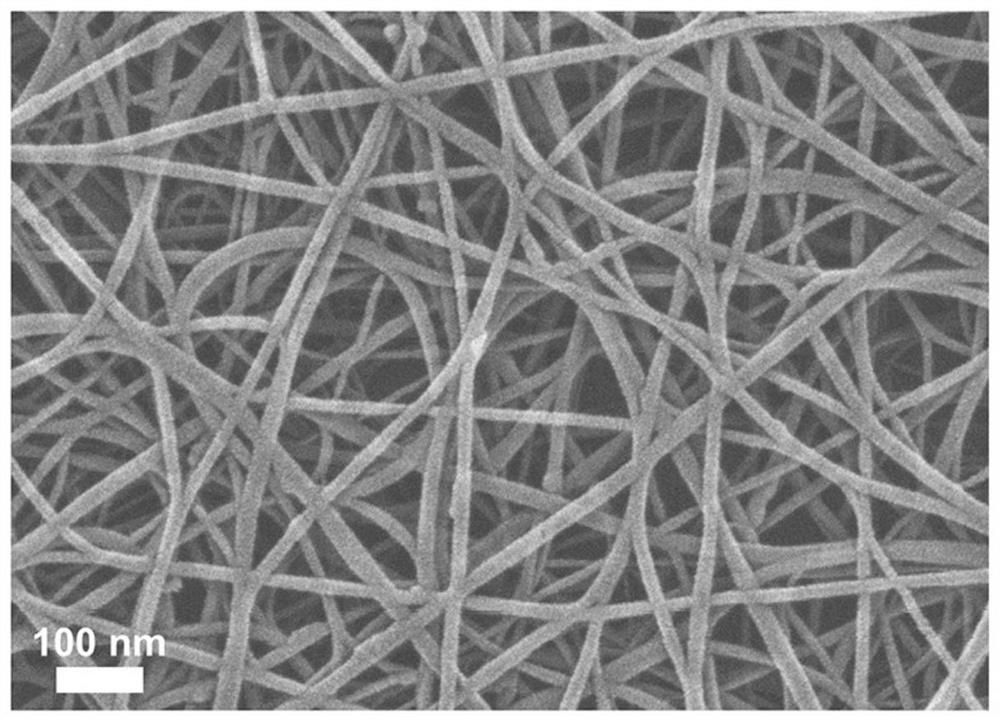

[0039] Single-walled carbon nanotubes were prepared by floating catalytic chemical vapor deposition, and the carbon nanotubes were sucked and filtered onto the filter membrane by a vacuum pump at the outlet. , 30min, 60min and 90min, transfer the single-wall carbon nanotube film deposited on the filter membrane to the PET substrate by pressing method, then cut it to a size of 2.0cm in length and 1.5cm in width, and stick it on the edge with a length of 1.5cm , a copper foil tape with a width of 2mm to obtain a single-walled carbon nanotube electrothermal film, see figure 1 (a), the transmission spectra of carbon nanotube films obtained at different suction filtration times are as follows figure 1 As shown in (b), it can be seen that the present invention can regulate the light transmittance of the single-walled carbon nanotube film by controlling the suction filtration time. Scanning electron microscopy (SEM) of single-walled carbon nanotube films figure 2 As shown, the car...

Embodiment 2

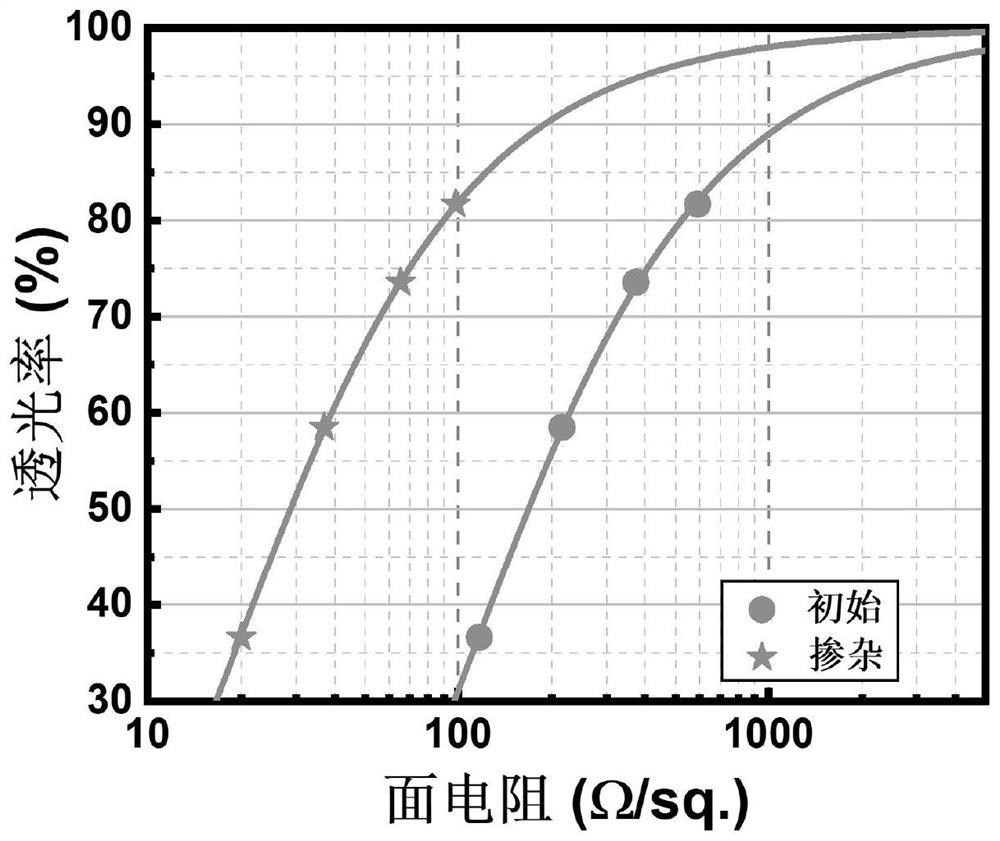

[0041] Single-walled carbon nanotubes were prepared by floating catalytic chemical vapor deposition, and the carbon nanotubes were sucked onto the filter membrane by a vacuum pump at the outlet. Transfer the single-walled carbon nanotube film deposited on the filter membrane to the PET substrate by pressing method, then cut it to a size of 4.0 cm in length and 4.0 cm in width, and stick a copper foil tape of 4.0 cm in length and 3 mm in width on the edge , to obtain single-walled carbon nanotube electrothermal film. The light transmittance of the single-walled carbon nanotube film can be regulated by controlling the suction and filtration time. The scanning electron microscope shows that the carbon nanotubes prepared by the method have high purity, and the carbon nanotubes are in close contact. When the filtration time is 30 minutes, the measured light transmittance of the carbon nanotube film is 83.3%, and the corresponding surface resistance is 588.4Ω / sq. Then use gold chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com