Multi-row single-base-island lead wire framework with glue locking holes and SOT33-5L encapsulation element thereof

A lead frame and glue hole technology is used in the field of electronic device manufacturing and semiconductor packaging, which can solve the problems of increasing the resistance, inductance and parasitic capacitance of IC devices, failing to achieve good heat conduction and signal output, and reducing the efficiency of high-frequency converters. , to achieve the improvement of sealing and waterproof and moisture-proof performance, improve processability and reliability, and achieve the effect of small length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

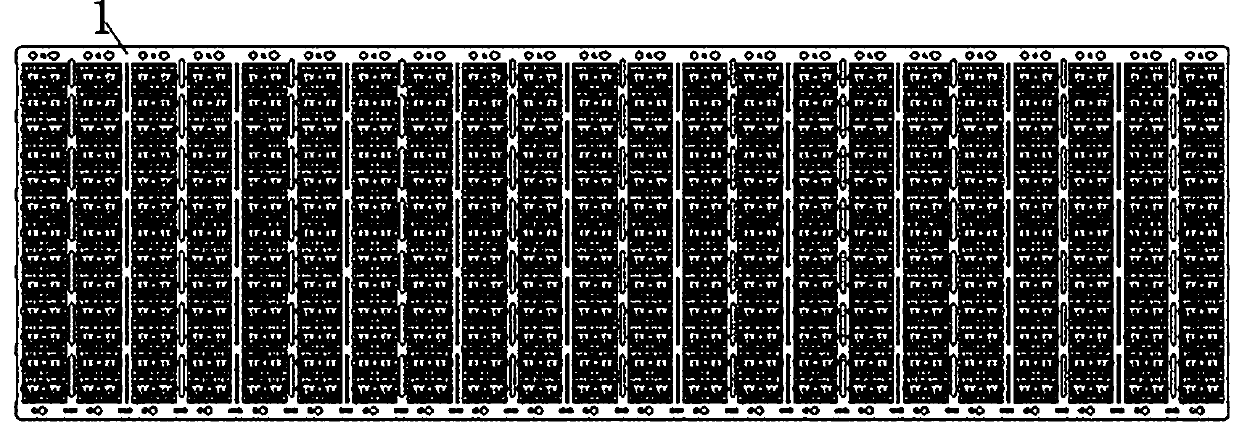

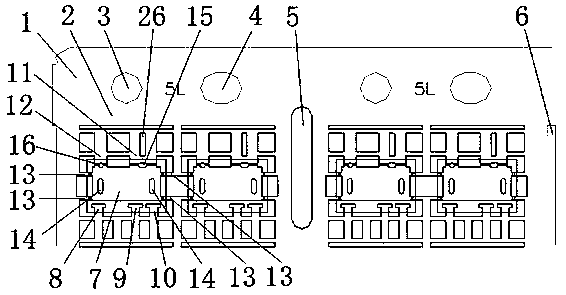

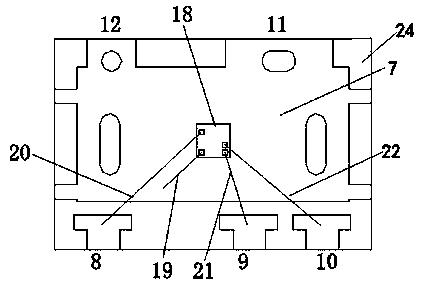

[0033] like Figure 1-2As shown, a lead frame with multiple rows of single-base islands with locking glue holes in this embodiment 1 includes a lead frame body 1 for electrically connecting the chip 18 to the external pin 25. The lead frame body 1 includes There are 13 rows and 44 columns, with a total of 572 frame units 2; the tops of lead frame units 2 in odd rows are provided with first anti-reversal holes 3, and the tops of lead frame units 2 in even rows are provided with second anti-reversal holes 4. In the present invention, every two lead frame units 2 form a group in the horizontal direction, and a process hole 5 is provided between each group of lead frame units 2 , and a first stress relief groove 6 is provided between each group of lead frame units 2 in the horizontal direction. The lead frame unit 2 includes a base island 7 whose size matches the chip 18. Five inner pins are arranged at the upper and lower ends of the base island 7, and the inner pin head and the ...

Embodiment 2

[0037] like figure 1 , Figure 5-7 As shown, the structure of a lead frame with multiple rows of single-base islands with locking glue holes in this embodiment 2 and the lead frame in embodiment 1, and the SOT33-5L package formed by using the lead frame in embodiment 2 and its implementation The difference in the structure of the package in Example 1 is that the distance between the second inner pin 9 and the third inner pin 10 is three times the distance between the first inner pin 8 and the second inner pin 9, so that The third inner pin 10 is distributed separately from the first inner pin 8 and the second inner pin 9 , so as to satisfy the package with high voltage requirements at the end of the third inner pin 10 . Other structures are with embodiment 1.

[0038] The production method of the SOT33-5L package is the same as in Embodiment 1.

Embodiment 3

[0040] like figure 1 , Figure 8-10 As shown, the difference between the structure of the lead frame with multiple rows of single-base islands with locking glue holes in Embodiment 3 and the lead frame in Embodiment 1 lies in that the fifth inner pin 12 located on the left side of the upper end of the base island 7 The head is not connected to the base island, the tail is rectangular, and its corresponding outer pin 25 is not connected to the base island 7, which can be used as an electrical output channel; the fourth inner pin and its corresponding outer pin are used as a heat dissipation channel ; Both sides of the base island are respectively provided with a first locking glue hole, and the fourth inner pin is connected with the base island to be provided with a second locking glue hole. Other structures are with embodiment 1.

[0041] The difference between the structure of the SOT33-5L package formed by using the lead frame in Embodiment 3 and the package in Embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com