Wind-driven magnetic suspension flywheel assisted power generation system

An auxiliary power generation and magnetic levitation technology, which is applied in wind power generation, wind turbines, wind turbine combinations, etc., can solve the problems of affecting the service life of the generator, the mechanical impact of the generator shaft, and the insufficient utilization of wind energy, so as to reduce the yaw power consumption. , Reduce mechanical impact, improve the effect of wind energy utilization space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawings and examples.

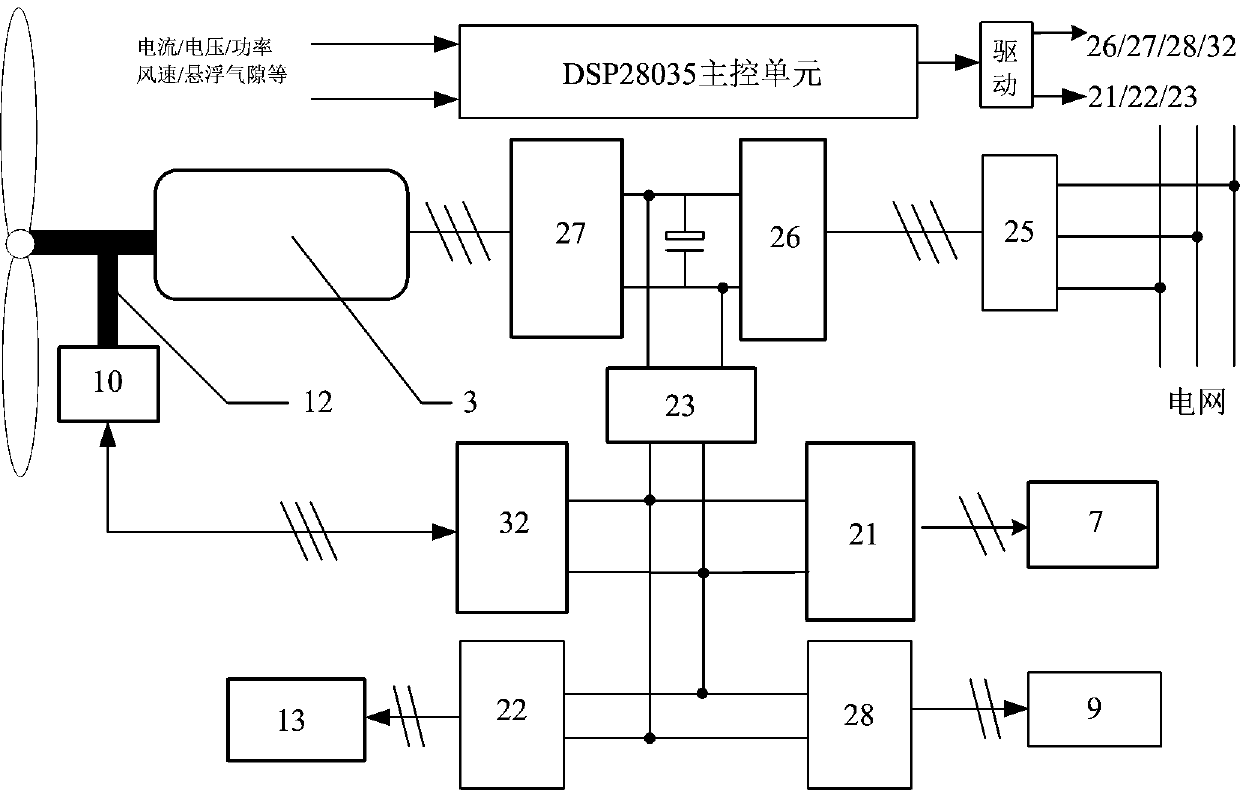

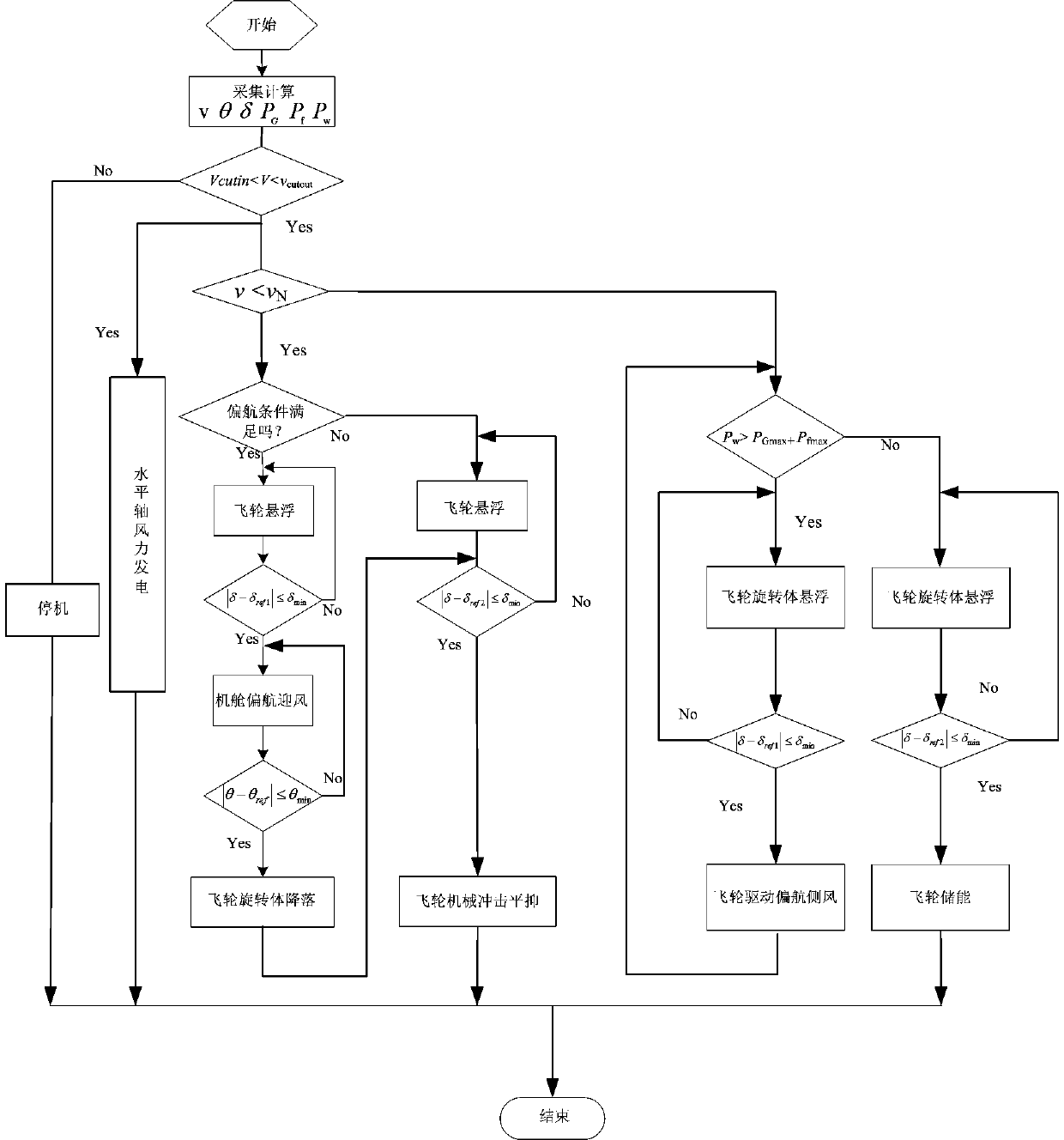

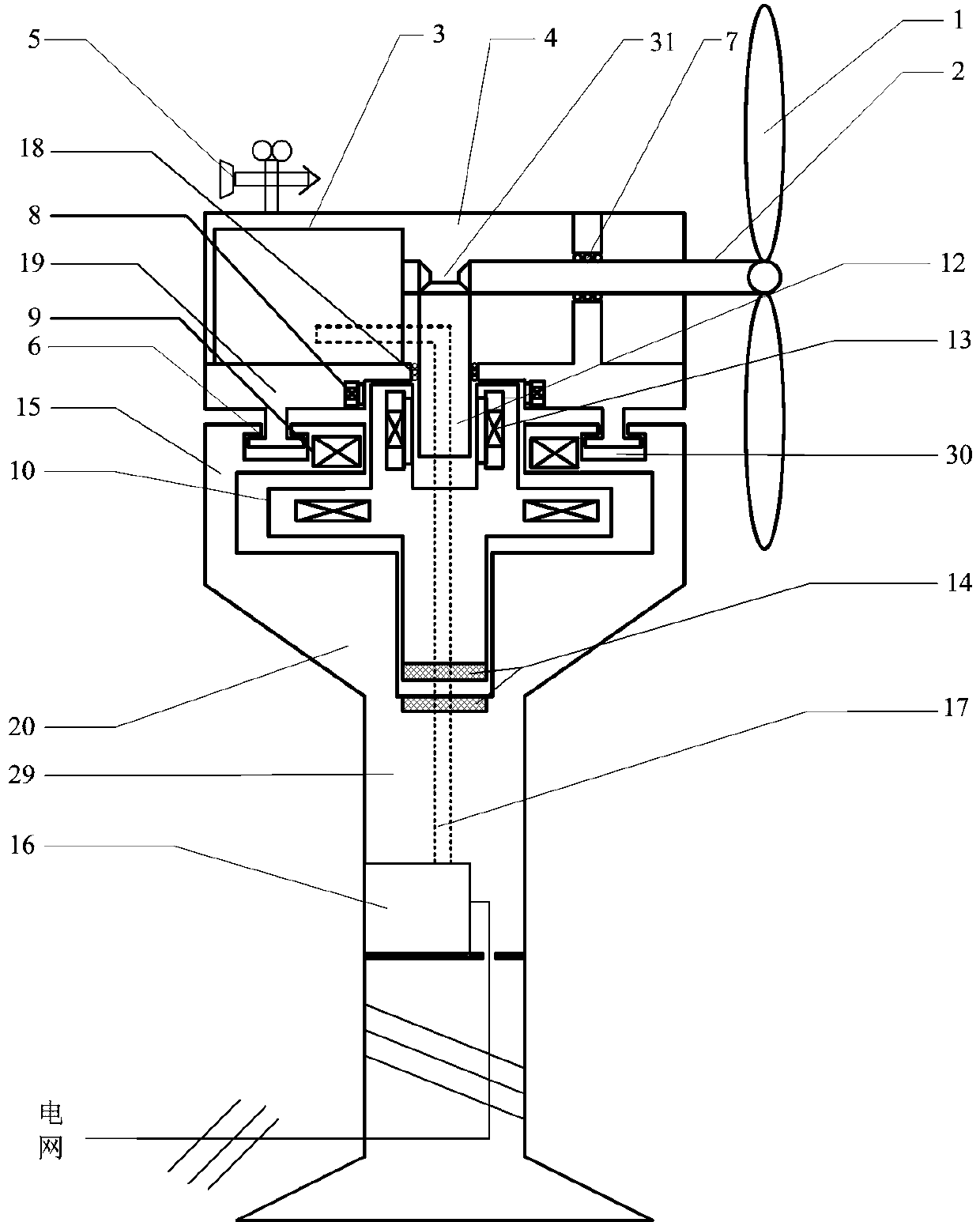

[0029] The wind-force maglev flywheel auxiliary power generation system disclosed in the present invention includes a nacelle 4, a generator 3, a nacelle rotating body 19, a flywheel rotating body 10, a flywheel yaw winding 11, a wind turbine limit bearing 7, a flywheel suspension winding 9, and a hybrid tower 20 (nacelle support 15 and tower bottom support 29), and the converter unit 16, cooperate to complete horizontal axis wind power generation, horizontal axis nacelle yaw and flywheel auxiliary energy storage; The electrical control part of the system, including machine side converter 27, grid side converter 26, step-up transformer 25, BUCK-BOOST converter 23, flywheel energy storage converter 32, flywheel suspension converter 21, flywheel lock The storage converter 22, the suspension damping converter 28, and the DSP28035 main control unit cooperate to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com