Nitrogen-doped and carbon-coated molybdenum carbide as well as preparation method and application thereof

A technology of carbon-coated molybdenum carbide and nitrogen doping, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve the effects of simple and controllable process, stable performance and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing nano-molybdenum carbide coated with nitrogen-doped carbon in this embodiment, the specific preparation steps are as follows:

[0044] Dissolve 12.2g of soluble sodium molybdate in deionized water, then add 12.2g of diammonium hydrogen citrate, add 3.7g of hydrazine hydrochloride after the dissolution is complete, then adjust the pH of the above solution to 6.0 with ammonia water, and react the above solution at 40°C 6h, then stirred and evaporated to dryness at 70°C for 12 hours to obtain a gel, and then dehydrated the gel at 120°C for 12 hours to obtain a xerogel. Grind the xerogel evenly, put it into a tube furnace for carbon reduction at 600°C for 2 hours, and inject 5% (v / v) H 2 H 2 / Ar mixed gas, the target product nitrogen-doped carbon-coated nano-molybdenum carbide can be obtained after the reaction.

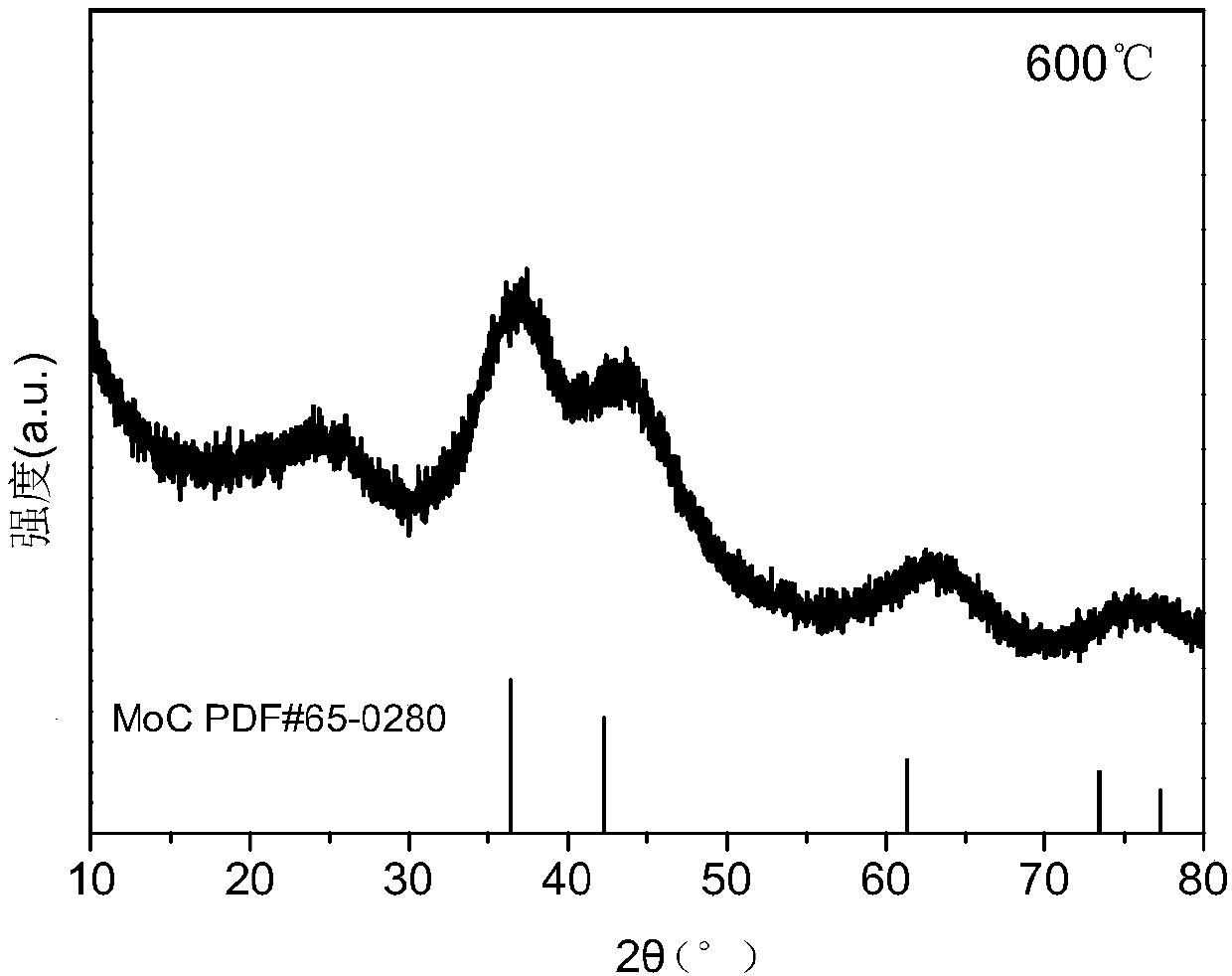

[0045] The XRD figure of the nano-molybdenum carbide coated with nitrogen-doped carbon obtained in the present embodiment is as follows f...

Embodiment 2

[0047] A method for preparing nano-molybdenum carbide coated with nitrogen-doped carbon in this embodiment, the specific preparation steps are as follows:

[0048] Dissolve 12.2g of soluble ammonium molybdate in deionized water, then add 12.2g of diammonium hydrogen citrate, add 3.7g of hydrazine hydrochloride after the dissolution is complete, then adjust the pH of the above solution to 6.5 with ammonia water, and react the above solution at 40°C 4h, then stirred and evaporated to dryness at 70°C for 12 hours to obtain a gel, and then dehydrated the gel at 140°C for 12 hours to obtain a xerogel. Grind the xerogel evenly, put it in a tube furnace for carbon reduction at 700°C for 2 hours, and pass 5% (v / v) H 2 H 2 / Ar mixed gas, the target product nitrogen-doped carbon-coated nano-molybdenum carbide can be obtained after the reaction.

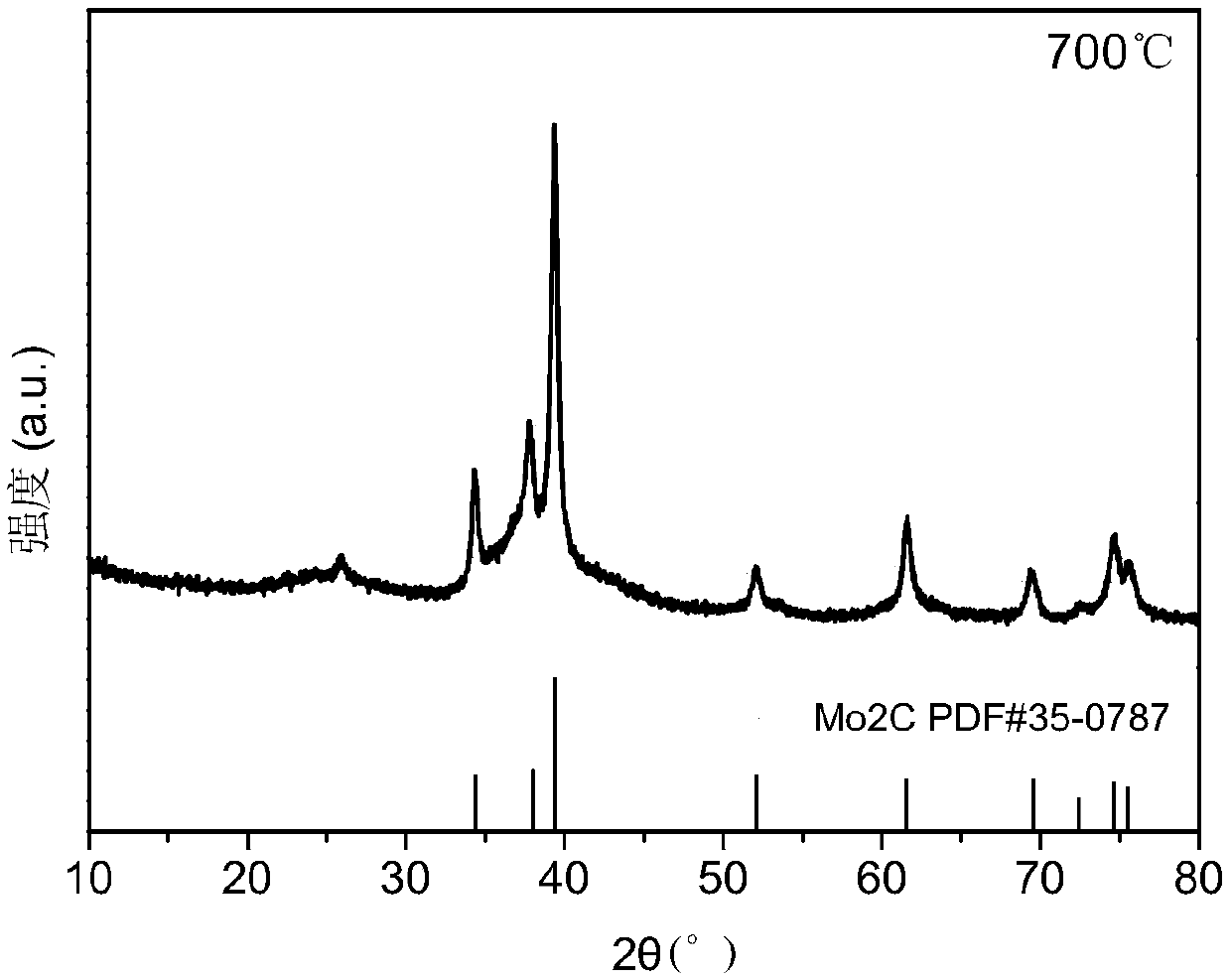

[0049] The XRD figure of the nano-molybdenum carbide coated with nitrogen-doped carbon obtained in the present embodiment is as follows fi...

Embodiment 3

[0051] A method for preparing nano-molybdenum carbide coated with nitrogen-doped carbon in this embodiment, the specific preparation steps are as follows:

[0052] Dissolve 12.2g of soluble ammonium molybdate in deionized water, then add 24.4g of diammonium hydrogen citrate, add 5.4g of hydrazine hydrochloride after the dissolution is complete, then adjust the pH of the above solution to 6.5 with ammonia water, and react the above solution at 40°C 4h, then stirred and evaporated to dryness at 80°C for 12 hours to obtain a gel, and then dehydrated the gel at 160°C for 12 hours to obtain a xerogel, ground the xerogel evenly, put it into a tube furnace at 800°C for carbon reduction 4 Hours, during the reaction, 10% (v / v) H 2 H 2 / Ar mixed gas, the target product nitrogen-doped carbon-coated nano-molybdenum carbide can be obtained after the reaction.

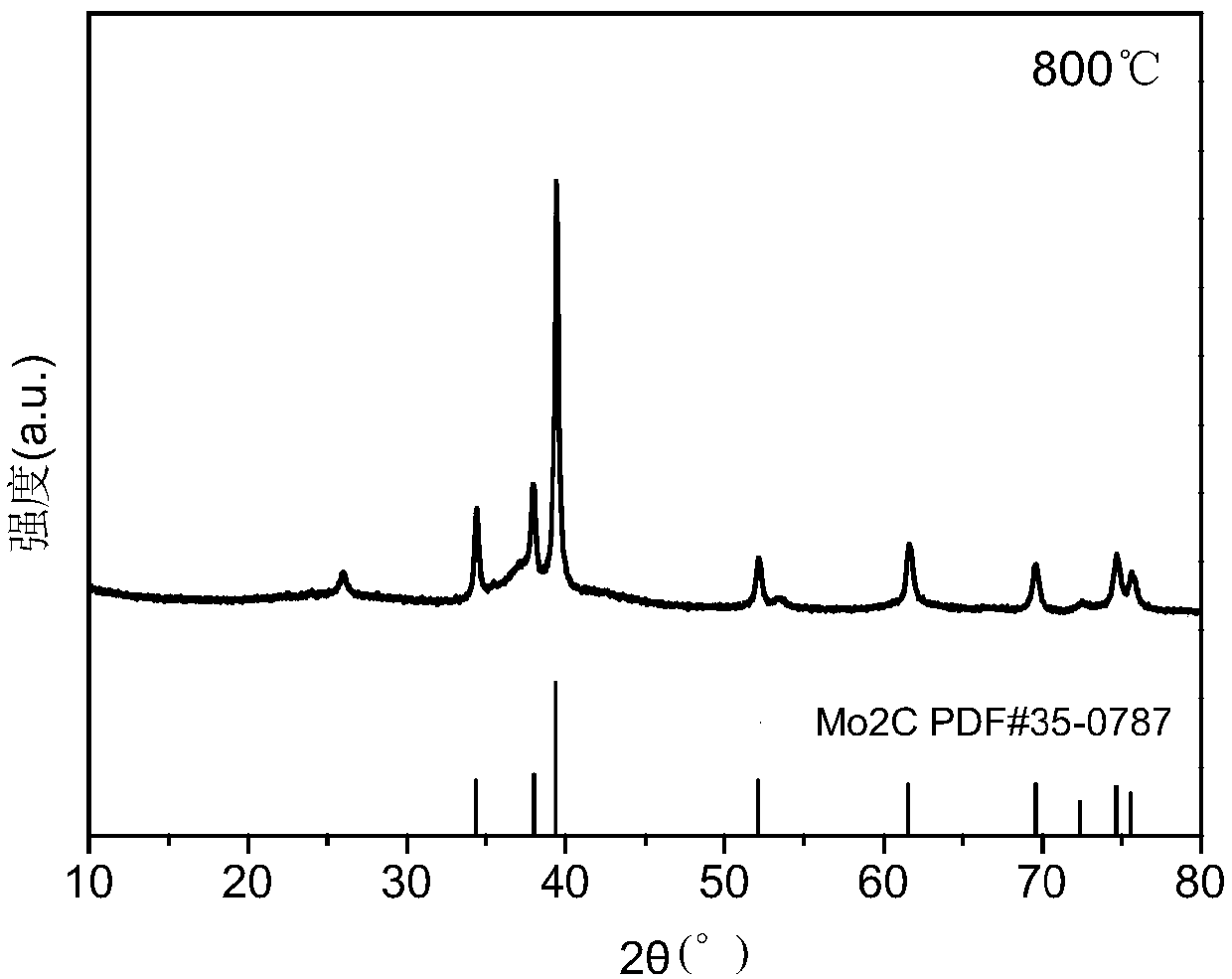

[0053] The XRD figure of the nano-molybdenum carbide coated with nitrogen-doped carbon obtained in the present embodiment is as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com