Synthesis method of SAPO-34 type molecular sieve of CHA structure and obtained MTO (Methanol To Olefins) catalyst

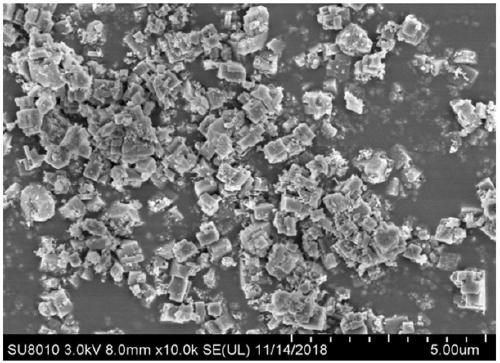

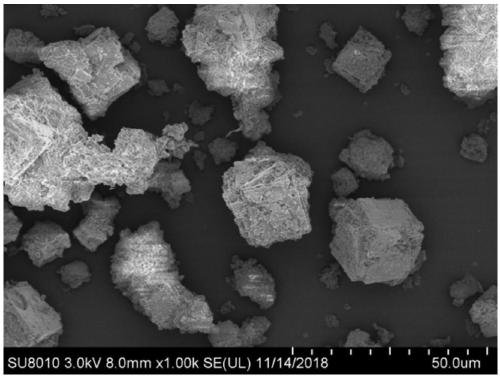

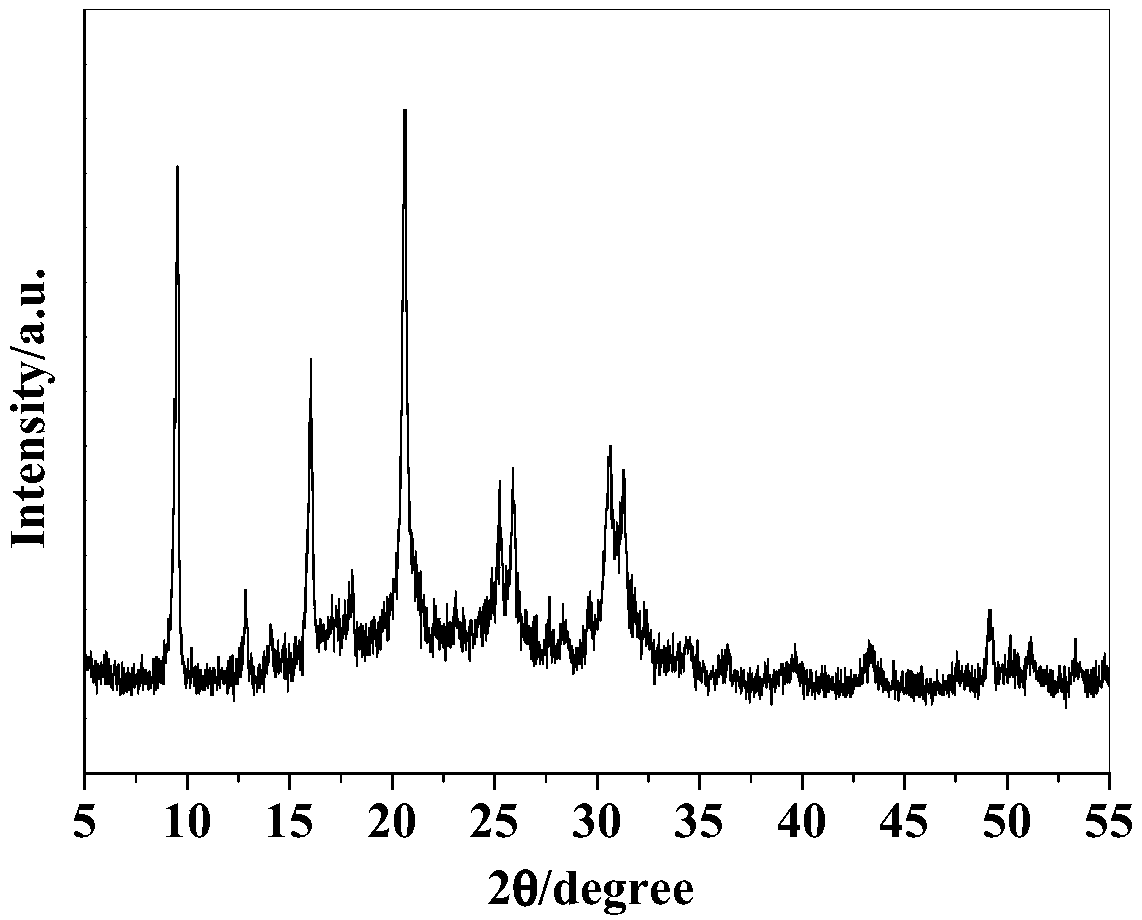

A technique for the synthesis of SAPO-34, applied in molecular sieve catalysts, molecular sieves and base-exchanged phosphates, physical/chemical process catalysts, etc., can solve the problem of synthetic samples mixed with amorphous phase products and miscellaneous crystals, which affect the stability of MTO process , uneven distribution, etc., to overcome the long crystallization time, improve crystallization synthesis efficiency, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Synthetic SAPO-34 type molecular sieve with CHA structure comprises the following steps:

[0044] Preparation of precursor synthesis liquid: mix 19.0g orthophosphoric acid and 85.0g deionized water evenly, add 15.0g acetylacetone at room temperature, slowly add 11.5g pseudo-boehmite to the above system under stirring and stir to form a uniform sol, then Add 30.4g of triethylamine dropwise to the above-mentioned sol system, then slowly add 1.80g of fumed silicon dioxide, and fully stir to form a precursor synthesis liquid, wherein the molar ratio of each raw material in the precursor synthesis liquid is: A l 2 o 3 :P 2 o 5 :ACAC:TEA:SiO 2 : H2O=1:1.1:2:4:0.4:70;

[0045] Precursor synthesis and liquid crystallization: the precursor synthesis solution was placed in a stainless steel crystallization kettle lined with polytetrafluoroethylene, and statically crystallized at 453K for 12 hours to obtain a crystallized product;

[0046] Separation of the crystallized produ...

Embodiment 2

[0052] The specific steps are the same as in Example 1, except that 3.00g acetylacetone is added, and the molar ratio of each raw material in the precursor synthesis liquid is: Al 2 o 3 :P 2 o 5 :ACAC:TEA:SiO 2 : H2O=1:1.1:0.4:4:0.4:70.

[0053] The quality of the synthesized product was 6.14 g, and the calculated yield was 29%.

[0054] Repeat the experiment on the SAPO-34 molecular sieve prepared by the above method for three times, and the yield error of the prepared molecular sieve is not more than 6%.

Embodiment 3

[0056] The specific steps are the same as in Example 1, except that 7.50g acetylacetone is added, and the molar ratio of each raw material in the precursor synthesis liquid is: Al 2 o 3 :P 2 o 5 :ACAC:TEA:SiO 2 : H2O=1:1.1:1:4:0.4:70.

[0057] The quality of the synthesized product was 7.15 g, and the calculated yield was 34%.

[0058] Repeat the experiment on the SAPO-34 molecular sieve prepared by the above method for three times, and the yield error of the prepared molecular sieve is not more than 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com