Low-cost high-strength light-weight ceramic body and preparation method thereof

A white cloud ceramic green body and high-strength technology, which is applied in the field of ceramic products, can solve the problems of energy saving and emission reduction of white cloud ceramics, reduce the degradation function of white cloud ceramics, and reduce the strength of white cloud ceramics, so as to promote sustainable development and expand firing The temperature range can be improved to improve the firing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

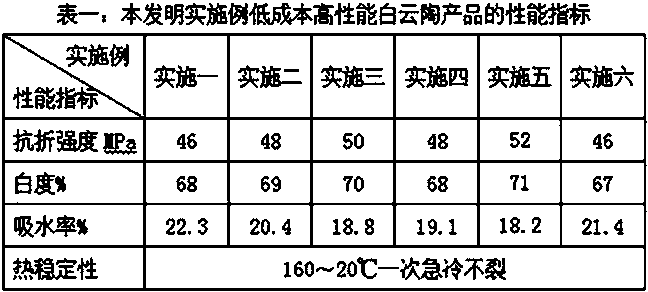

Examples

Embodiment 1

[0022] In this embodiment, the base material includes the following raw materials by weight percentage: 28wt% of elutriation mud, 12wt% of black clay, 1wt% of bentonite, 5wt% of pyrophyllite, 12wt% of low-temperature sand, 4wt% of lithium china stone, and 10wt% of dolomite %, black talc 6wt%, limestone 8wt%, diopside 9wt%, Yongchun coarse soil 2wt%, waste porcelain powder 3wt%; the weight percentage of the additive relative to the base material is 1%. The additive is organosilicon nano liquid, and its weight percentage relative to the base material is 1%.

[0023] The preparation method of the low-cost high-strength white cloud ceramic body of the present embodiment includes the following specific steps:

[0024] (1) Carry out wheel milling, elutriation, sieving, and iron removal of inferior raw materials to prepare elutriation mud;

[0025] (2) ball milling the elutriation mud prepared in step (1) and other raw materials in the base material in a ball mill respectively by we...

Embodiment 2

[0029] In this embodiment, the base material includes the following raw materials by weight percentage: 30wt% of elutriation mud, 15wt% of black clay, 6wt% of pyrophyllite, 13wt% of low-temperature sand, 5wt% of lithium china stone, 7wt% of dolomite, black talc 6wt%, limestone 7wt%, diopside 10wt%, Yongchun coarse soil 1wt%. The additive is organosilicon nano liquid, and its weight percentage relative to the base material is 2%.

[0030] The preparation method of the low-cost high-strength white cloud ceramic body of the present embodiment includes the following specific steps:

[0031] (1) Carry out wheel milling, elutriation, sieving, and iron removal of inferior raw materials to prepare elutriation mud;

[0032] (2) ball milling the elutriation mud prepared in step (1) and other raw materials in the base material in a ball mill respectively by weight percentage until the mixture particles pass through a 200-250 mesh sieve, and then the mud is used for subsequent use;

[0...

Embodiment 3

[0036]In this embodiment, the base material includes the following raw materials by weight percentage: 32wt% of elutriation mud, 15wt% of black clay, 1wt% of bentonite, 5wt% of pyrophyllite, 13wt% of low-temperature sand, 5wt% of lithium china stone, and 10wt% of dolomite %, black talc 7wt%, limestone 7wt%, diopside 8wt%; the weight percentage of the additive relative to the base material is 1%. The additive is organosilicon nano liquid, and its weight percentage relative to the base material is 1%.

[0037] The preparation method of the low-cost high-strength white cloud ceramic body of the present embodiment includes the following specific steps:

[0038] (1) Carry out wheel milling, elutriation, sieving, and iron removal of inferior raw materials to prepare elutriation mud;

[0039] (2) ball milling the elutriation mud prepared in step (1) and other raw materials in the base material in a ball mill respectively by weight percentage until the mixture particles pass through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hygroscopic ratio | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com