Method for preparing starch carbonic ester by utilizing starch/CO2 and application of starch carbonic ester

A technology of CO2 and carbonate, which is applied in the field of starch carbonate preparation using starch/CO2, which can solve the problem of not being green

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

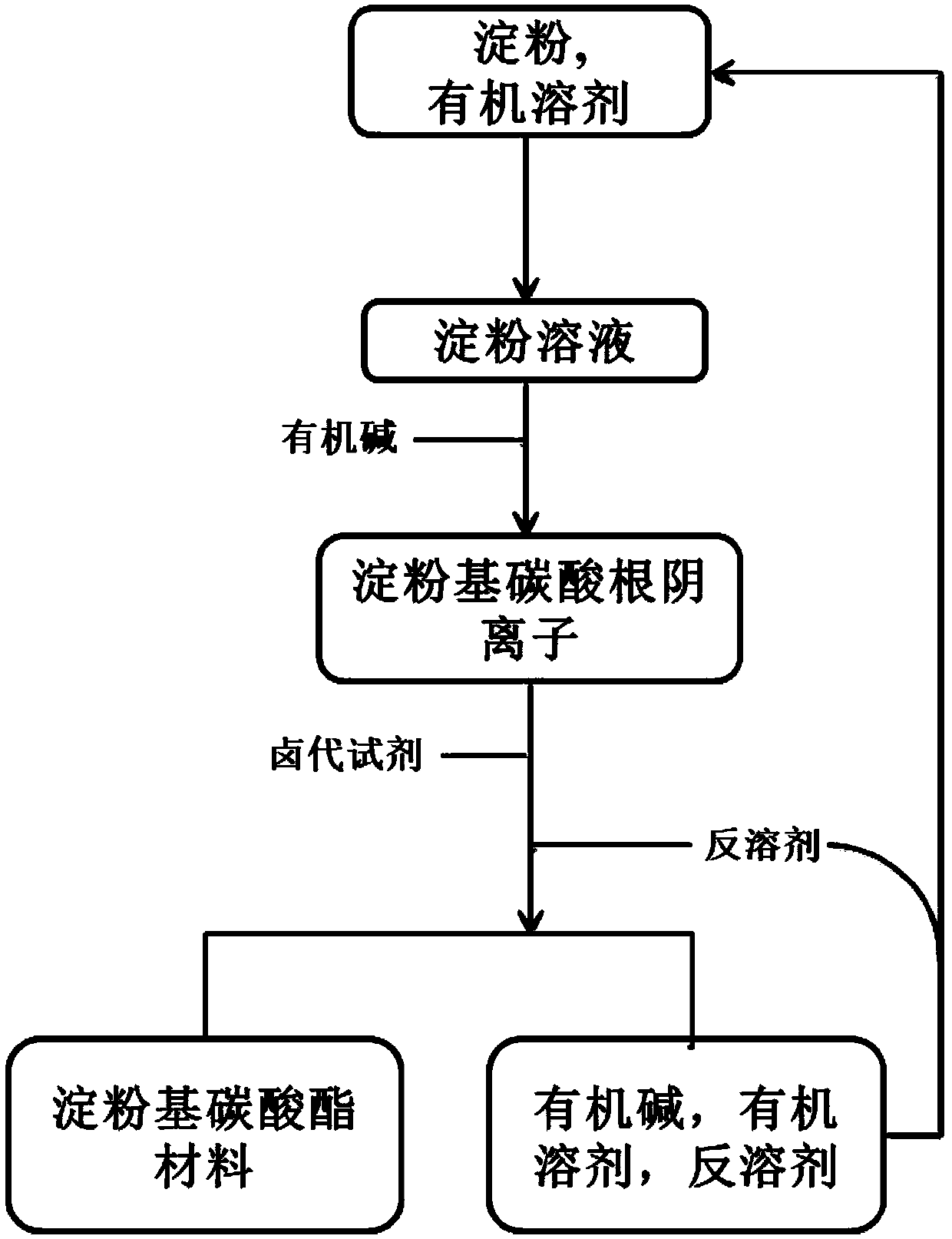

Method used

Image

Examples

experiment example 1

[0084] In order to illustrate the applicable protection scope of the starch of the present invention, we use different types of starch to synthesize starch carbonate materials.

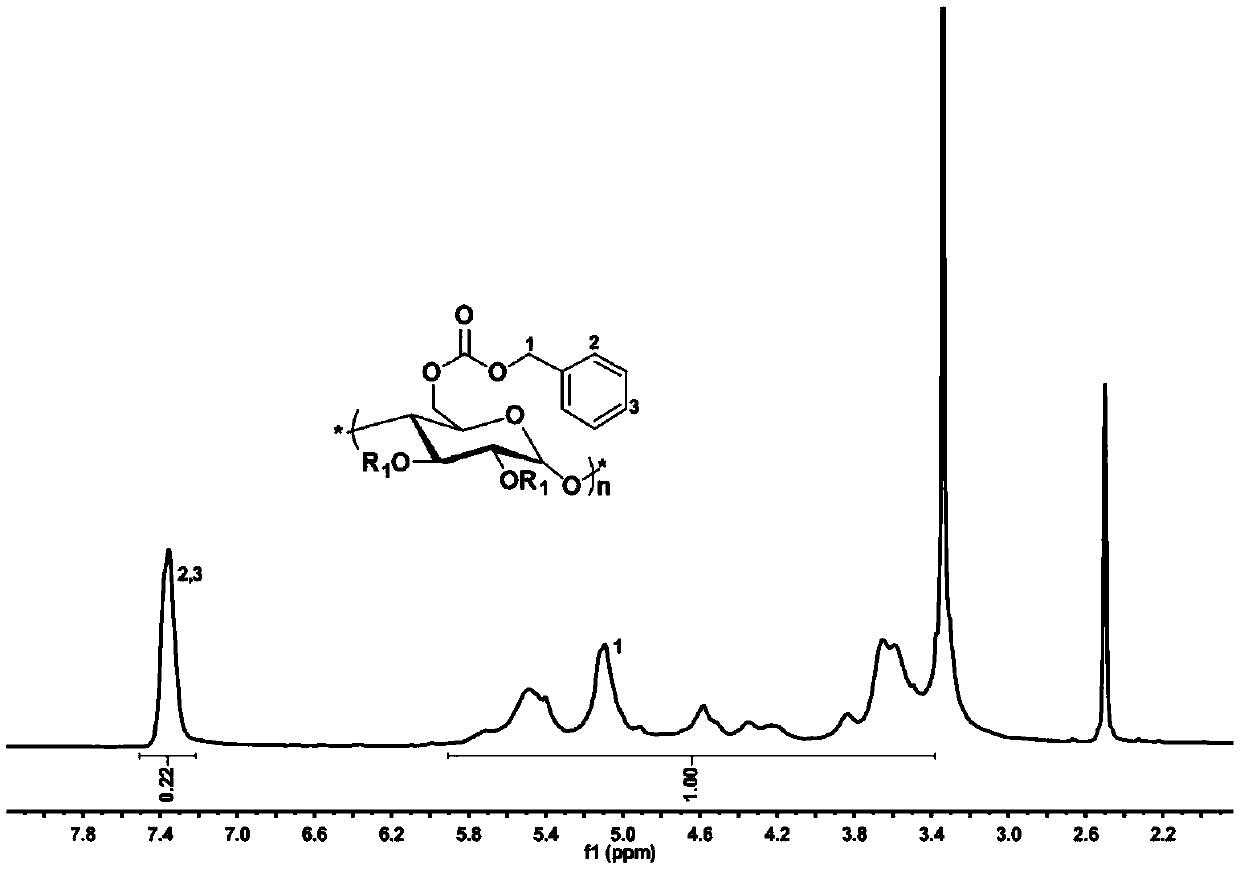

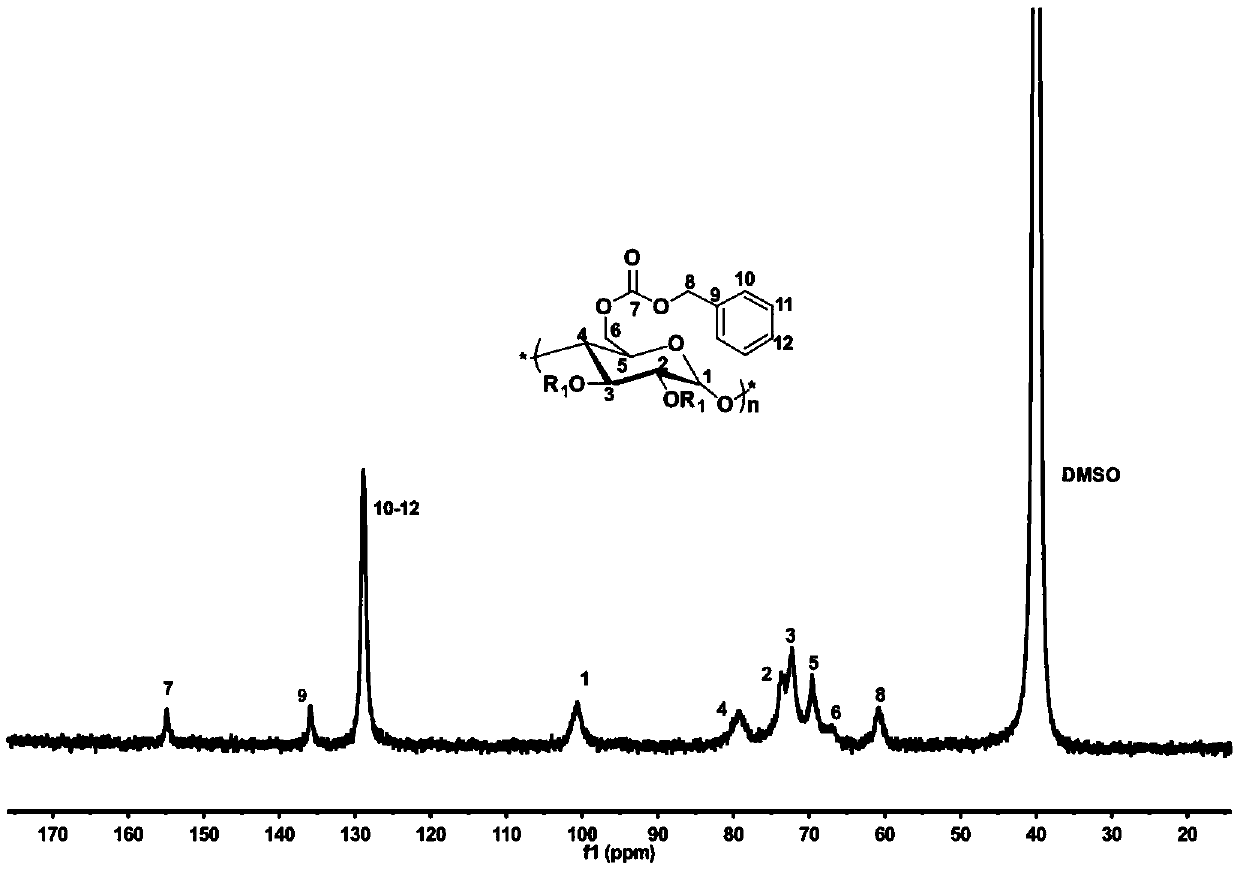

[0085] Take DMSO (15.3g) and add it to the reactor, then add DBU (18.51mmol2.8182g) and stir and mix evenly at room temperature, then add different types of starch (6.17mmol1g) and stir and mix at room temperature, so that the cornstarch is uniformly dispersed in DMSO, Maintain the reaction system CO 2 The pressure is 1.0MPa. The reaction kettle was moved into a 30°C oil bath for 3h reaction, and a translucent liquid was obtained after the reaction. Then cool to room temperature and add benzyl bromide (18.51mmol2.2mL) in situ and then react at 30°C and 4Mpa for 24h. After the reaction, a transparent light yellow liquid is obtained, which is precipitated by adding 100mL of ethanol drop by drop. After separation by filtration, use Washed once with 100 mL of ethanol to obtain a white powder.

[0086] ...

experiment example 2

[0091] In order to illustrate the applicable protection scope of the halogenated reagent of the present invention, we synthesized starch carbonate materials with different structures by using halogenated reagents with different structures.

[0092] Get DMSO (15.3g) and add in the reactor, then add DBU (18.51mmol2.8182g) and stir and mix at room temperature, then add cornstarch (6.17mmol1g) and stir and mix at room temperature, so that cornstarch is uniformly dispersed in DMSO, maintaining Reaction system CO 2 The pressure is 5MPa. The reaction kettle was moved into a 50° C. oil bath for 10 hours of reaction, and a translucent liquid was obtained after the reaction was completed. Then cool to room temperature and add a halogenating reagent in situ (the molar ratio of -X to -OH on the cellulose is 1:1), and then react at 30°C and 4Mpa for 24h. After the reaction, a transparent light yellow liquid is obtained. 100 mL of methanol was added dropwise to precipitate out, separated ...

experiment example 3

[0098] In order to illustrate the applicable protection scope of the organic base of the present invention, we synthesized starch carbonate materials by using different types of organic bases.

[0099] Take DMSO (15.3g) into the reaction kettle, then add different organic bases (18.51mmol2.8182g) and stir and mix at room temperature, then add corn starch (6.17mmol1g) and stir and mix at room temperature, so that the corn starch is evenly dispersed in DMSO , to maintain the reaction system CO 2 The pressure is 0.1 MPa. The reaction kettle was moved into an oil bath at 80° C. for 1 h, and a translucent liquid was obtained after the reaction was completed. Then cool to room temperature and add a halogenating reagent in situ (the molar ratio of -X to -OH on the cellulose is 1:1), and then react at 30°C and 4Mpa for 24h. After the reaction, a transparent light yellow liquid is obtained. Add 200mL of water dropwise to precipitate, filter and separate, and then wash with 200mL of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com