A kind of production method of copolymerized petroleum resin

A technology of copolymerized petroleum resin and production method, which is applied in the field of organic chemical production, can solve problems such as high softening point and deep hue, and achieve the effects of reducing energy consumption, light color number, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0026] A kind of production method of novel copolymerized petroleum resin mainly comprises following processing steps:

[0027] (1) Preparation of raw material A: Ethylene tar raw material is subjected to vacuum distillation, the distillation gas phase temperature is 240°C, and the pressure is -0.09MPa to obtain C9~C11 fractions, and then rectified to remove naphthalene, and the tower top temperature is 100 at the pressure -0.08Mpa Fraction at ~120 °C. Obtain C9~C10 fraction as raw material A;

[0028] (2) Preparation of raw material B: cracking C5 raw material, thermal polymerization reaction, the process conditions are reaction temperature 90 ° C, reaction pressure 0.1 MPa to polymerize cyclopentadiene into dicyclopentadiene, and then remove dicyclopentadiene by rectification ene to obtain high-purity C5 as raw material B; the process conditions for the rectification to remove dicyclopentadiene are as follows: under the pressure of 0.11Mpa, the fraction with a temperature o...

specific Embodiment 2

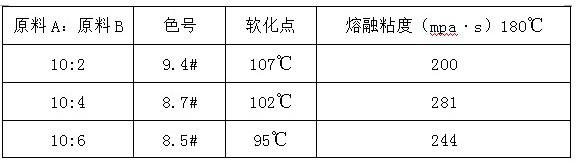

[0035] Under the experimental conditions of specific example 1, the results of the impact of raw materials A and B in different weight ratios on the obtained copolymerized petroleum resin are shown in the appendix of the description. figure 1 Comparison of data in the table.

[0036] From figure 1 It can be seen that under the condition of keeping the amount of raw material A constant, with the increase of raw material B, the softening point presents a downward trend, the color number gradually becomes lighter, and the viscosity gradually increases; according to market demand, the mass ratio of raw material A to raw material B 10:4 is the best process condition.

specific Embodiment 3

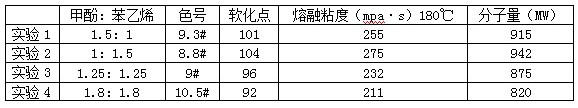

[0038] Under the experimental conditions of specific example 1, the results of the influence of cresol and styrene in different weight ratios on the obtained copolymerized petroleum resin are shown in the appendix of the description. figure 2 Comparison of data in the table.

[0039] From figure 2 Visible, under the situation that keeps raw material A, raw material B, diluent addition constant, change the ratio of cresol and styrene: under the situation that the total addition of cresol and styrene is constant, the addition of cresol is much, The color number is darker and the softening point is lower; more styrene is added, the color number is lighter, the softening point is higher, and the viscosity and molecular weight are higher; in experiment 4, the total addition of cresol and styrene is increased, and the softening point shows a downward trend , the color is further deepened, and the viscosity and molecular weight are gradually reduced. On the whole, the experimenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com