Grouting method of microcrack rock mass

A fractured rock mass and fine technology, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of limited slurry diffusion range, high flow effect, increased grouting pressure, etc., and achieves good perfusion effect and good flow. The effect of improving the water blocking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

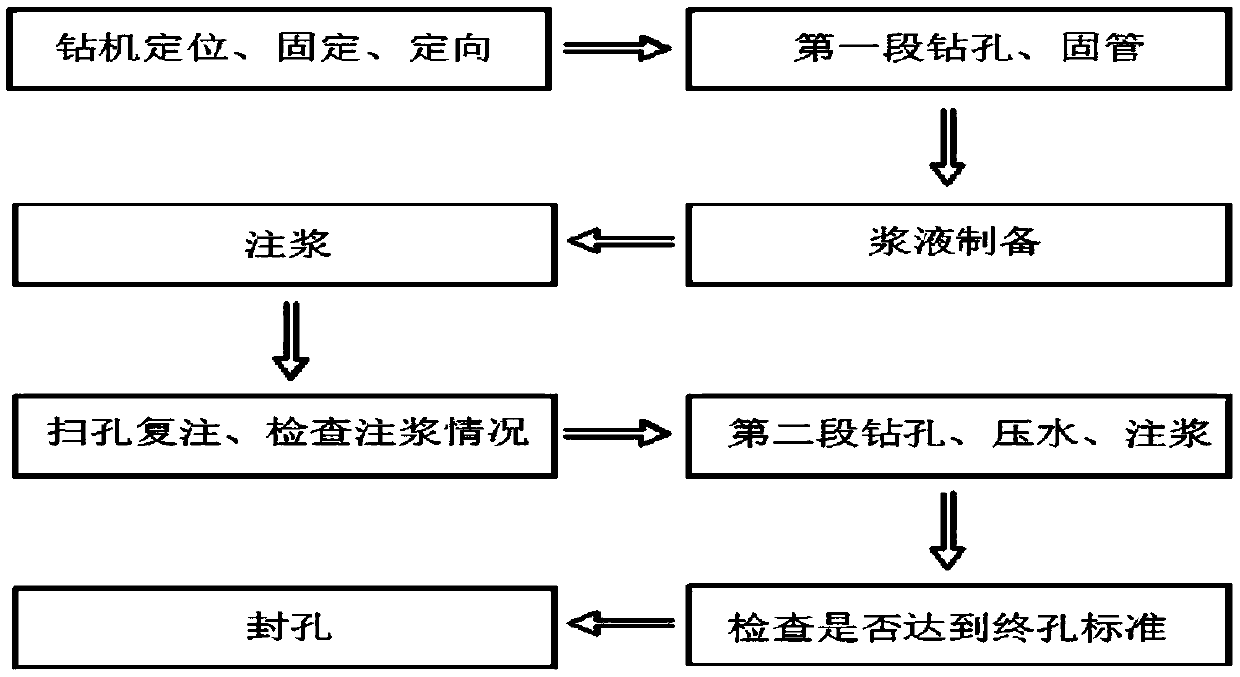

[0027] Such as Figure 1 to Figure 3 As shown, a grouting method for micro-cracked rock mass specifically includes the following steps:

[0028] Step 1: Position, fix and orient the drilling rig for construction;

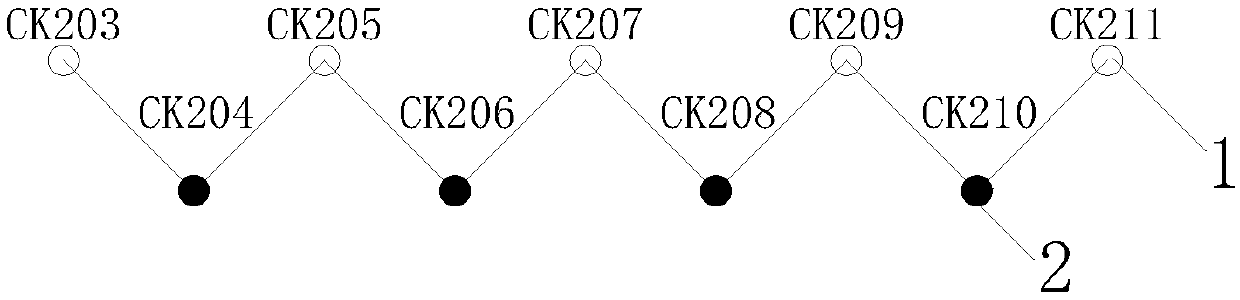

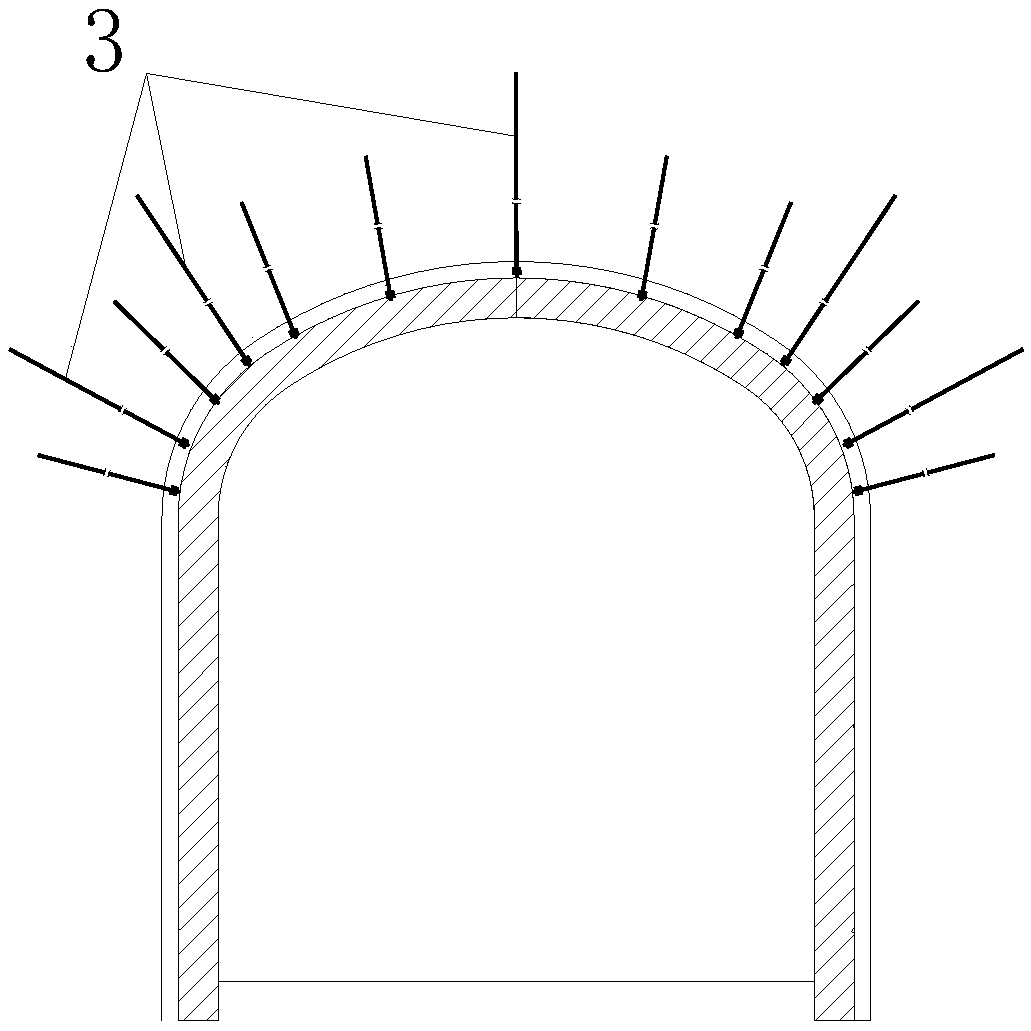

[0029] Step 2: Carry out the first section of drilling construction to form the first sequence hole 1, and fix the grouting pipe 3 with a diameter of 32mm in the first sequence hole 1 with cement water glass double slurry by increasing the grouting pressure;

[0030] Step 3: adapting bentonite cement and ordinary Portland cement to prepare grout;

[0031] Step 4: inject the prepared grouting slurry into the grouting pipe 3;

[0032] Step 5: Sweep the hole for re-injection and check the grouting situation;

[0033] Step 6: After the grouting of the first sequence hole 1 is completed, the second section of drilling is carried out to form the second sequence hole 2, and then the water pressure and grouting construction are carried out;

[0034] Step 7: Check whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com