Preparation method of bamboo fiber pulp

A technology of bamboo fiber pulp and pulp, which is applied in the field of papermaking, can solve the problems that the average fiber quality cannot meet the needs of high-end products, the number of recycling of national waste is high, and the resources of OCC waste paper are limited, etc., so as to achieve excellent chemical resistance and reduce The effect of papermaking cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

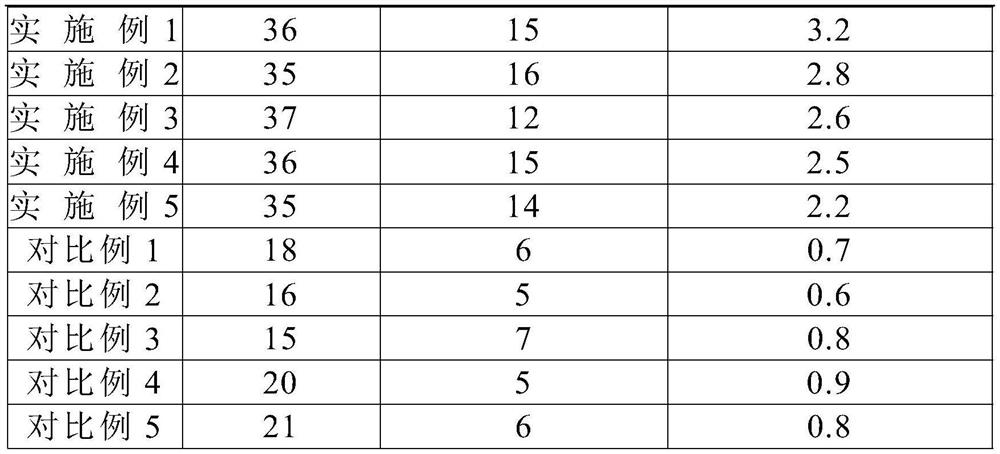

Examples

Embodiment 1

[0031] A kind of preparation method of bamboo fiber pulp in the present embodiment, comprises the following steps:

[0032] 1) Screening treatment: The raw materials are first added to the disc sieve, the larger debris is removed, and the pieces screened by the disc sieve are added to the vibrating screen machine to screen out the large pieces, and the large pieces are cut. After treatment, then after screening, the qualified bamboo chips are screened out;

[0033] 2) Steaming preheating: After adding the bamboo chips to the tablet processor for cleaning, dewatering by the screw dehydrator, and then crushing by the hammer crusher to obtain coarse pulp, which is transported to the steaming bin by the heating screw conveyor Preheating, the coarse pulp is heated and heated under the action of steam, preheated for 2 minutes, and the outlet temperature of the coarse pulp after preheating is 65 °C;

[0034] 3) High-consistency mill: add the coarse pulp to the heating screw conveyor...

Embodiment 2

[0038] A kind of preparation method of bamboo fiber pulp in the present embodiment, comprises the following steps:

[0039] 1) Screening treatment: The raw materials are first added to the disc sieve, the larger debris is removed, and the pieces screened by the disc sieve are added to the vibrating screen machine to screen out the large pieces, and the large pieces are cut. After treatment, then after screening, the qualified bamboo chips are screened out;

[0040] 2) Steaming preheating: After adding the bamboo chips to the tablet processor for cleaning, dewatering by the screw dehydrator, and then crushing by the hammer crusher to obtain coarse pulp, which is transported to the steaming bin by the heating screw conveyor Preheating, the brown pulp is heated and heated under the action of steam, preheated for 15 minutes, and the outlet temperature of the brown pulp after preheating is 85 °C;

[0041] 3) High-consistency mill: add the coarse pulp to the heating screw conveyor ...

Embodiment 3

[0045] A kind of preparation method of bamboo fiber pulp in the present embodiment, comprises the following steps:

[0046] 1) Screening treatment: The raw materials are first added to the disc sieve, the larger debris is removed, and the pieces screened by the disc sieve are added to the vibrating screen machine to screen out the large pieces, and the large pieces are cut. After treatment, then after screening, the qualified bamboo chips are screened out;

[0047] 2) Steaming preheating: After adding the bamboo chips to the tablet processor for cleaning, dewatering by the screw dehydrator, and then crushing by the hammer crusher to obtain coarse pulp, which is transported to the steaming bin by the heating screw conveyor Preheating, the coarse pulp is heated and heated under the action of steam, preheated for 5 minutes, and the outlet temperature of the coarse pulp after preheating is 70 °C;

[0048] 3) High-consistency mill: Add the coarse pulp to the heating screw conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com