Single component HJT battery low temperature silver paste

A single-component, low-temperature technology, applied in the direction of conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve the problem of poor balance of adhesion and resistivity, insufficient aging resistance, and the need to improve contact To achieve the balance of adhesion and conductivity, optimize the printing screen performance, and improve the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

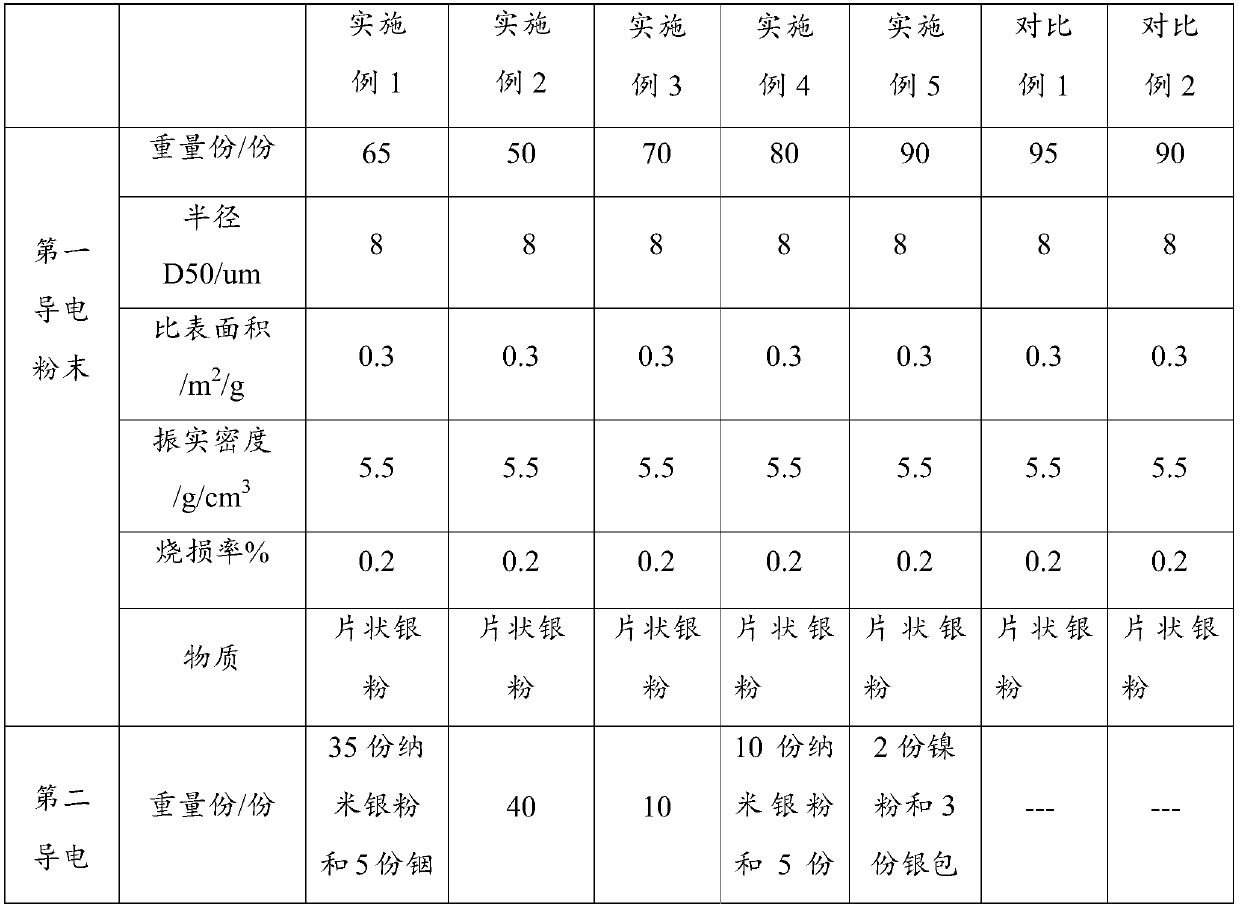

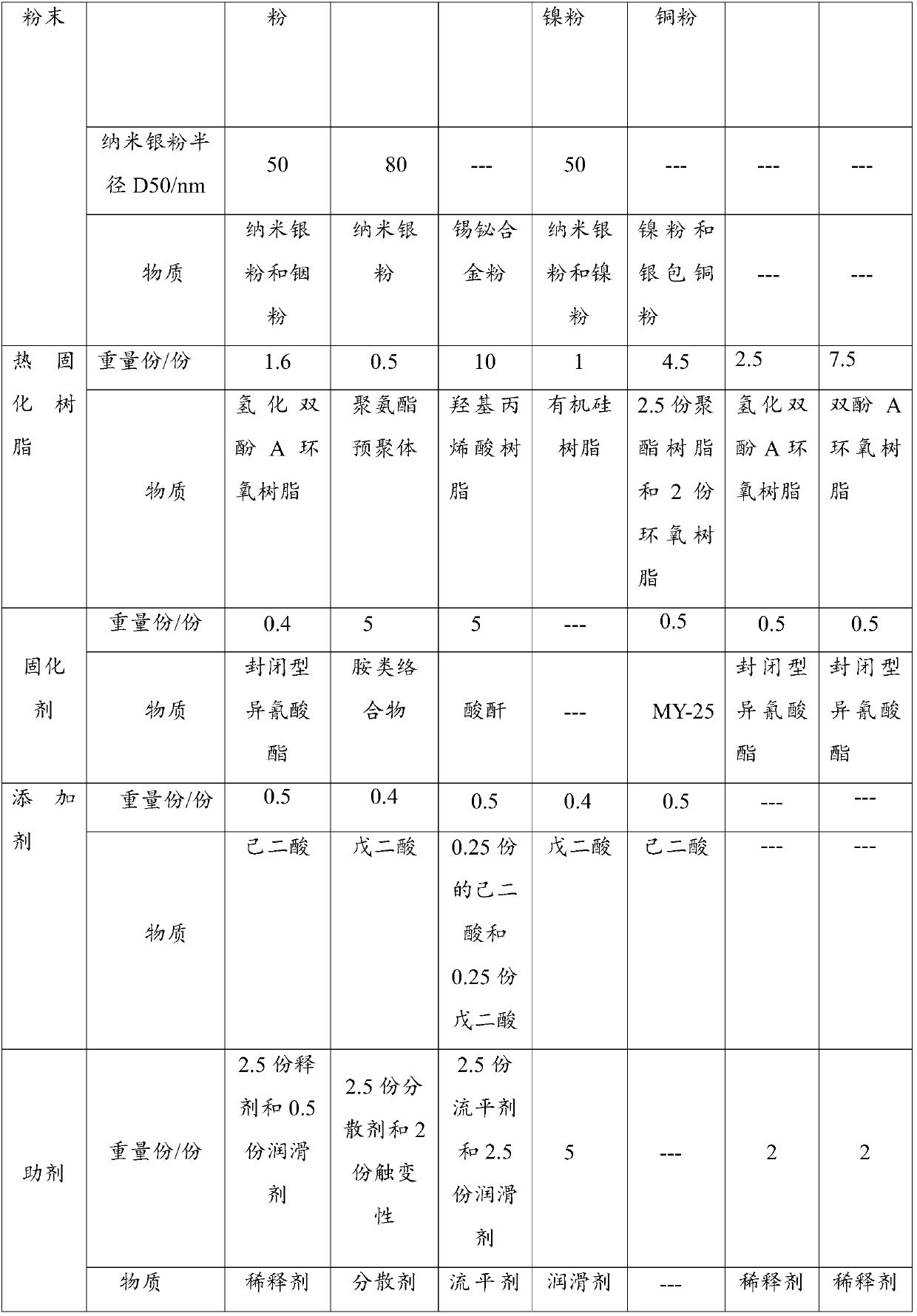

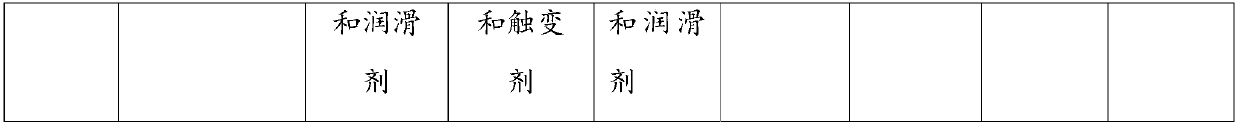

[0039] An example of a low-temperature silver paste for a single-component HJT battery of the present invention, the composition of the low-temperature silver paste for a single-component HJT battery in this example is shown in Table 1.

[0040] The preparation method of the low-temperature silver paste for the single-component HJT battery shown in this embodiment is:

[0041] After weighing according to the formula, mix and stir the resin, the first conductive powder, and the second conductive powder on a planetary mixer platform according to (1000 rpm / min) for 70 seconds, roll after stirring, and then add curing agent, auxiliary After the agent is passed through a three-roll mill.

Embodiment 2~5 and comparative example 1-2

[0043] The composition components of Examples 2-5 and Comparative Examples 1-2 are as shown in Table 1, and the preparation method of the single-component HJT battery low-temperature silver paste described in Examples 2-5 and Comparative Examples 1-2 is the same as that in Example 1.

[0044] The burning loss rate is the burning loss rate measured at 500°C for 30 minutes.

[0045] Simultaneously, the following properties of the low-temperature silver paste for single-component HJT batteries described in Examples 1 to 5 and Comparative Examples 1 to 2 were tested: resistivity after curing, adhesion, photolysis resistance, aging resistance, printing screen performance, Product service life, linear aspect ratio after curing. Among them, the test methods for each performance are:

[0046] Resistivity after curing: Print a fixed pattern (serpentine pattern with a length of 10cm and a width of 1mm), and measure the resistance value after curing. Calculate the resistivity accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com