High-density phase change memory and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

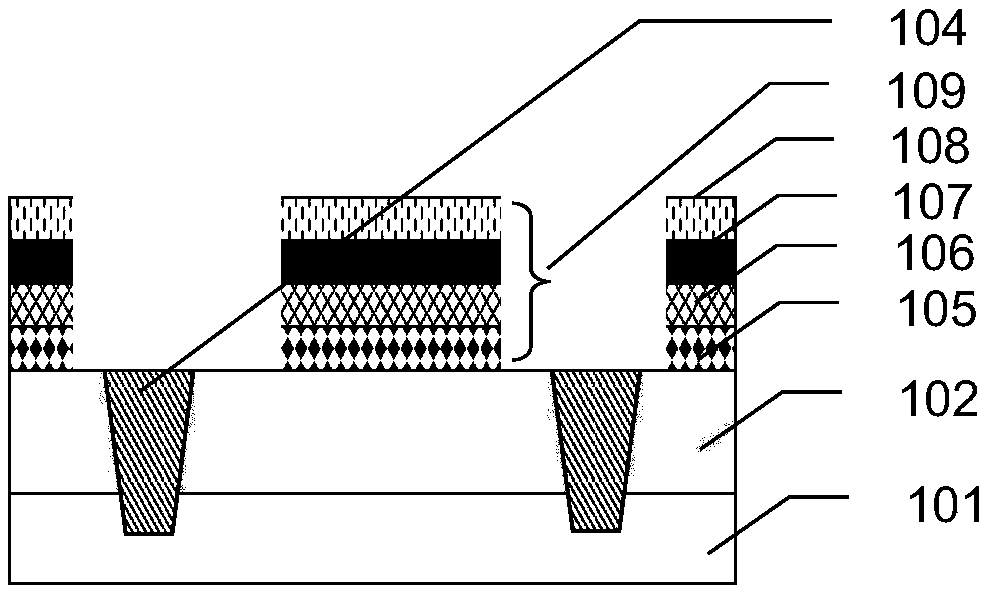

[0045] In the following specific embodiments of the present invention, please refer to figure 1 ,figure 1 It is a schematic structural diagram of a high-density phase-change memory according to the preferred embodiment 1 of the present invention. Such as figure 1 As shown, a high-density phase-change memory of the present invention includes: Schottky diodes 105 and 106 , a phase-change layer 107 and an upper electrode 108 from bottom to top. Wherein, the Schottky diode includes a semiconductor layer 105 and a metal layer 106 capable of forming a Schottky barrier with the semiconductor layer 105 ; the metal layer 106 also serves as a lower electrode of the phase change layer 107 .

[0046] The high density phase change memory of the present invention can be disposed on a semiconductor substrate 101 . The semiconductor layer 105, the metal layer 106, the phase change layer 107 and the upper electrode 108 have a flat layer structure stacked from bottom to top.

[0047] In this...

Embodiment 2

[0054] Please refer to Figure 2-Figure 7 , Figure 2-Figure 7 is prepared figure 1 A schematic diagram of the process steps of a high-density phase-change memory. Such as Figure 2-Figure 7 As shown, a method for preparing a high-density phase-change memory of the present invention can be used to prepare a high-density phase-change memory in the first embodiment above, and may include the following steps:

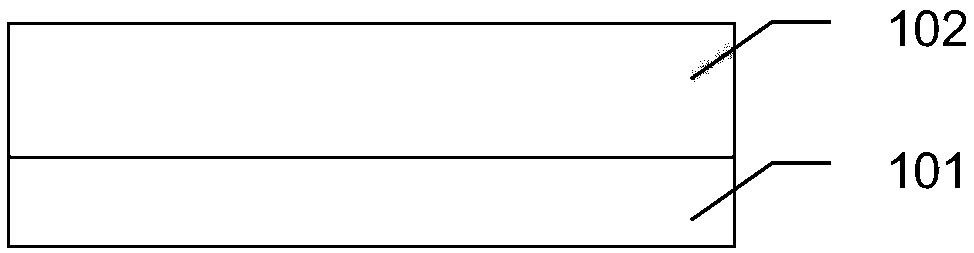

[0055] Step S01: providing a P-type semiconductor substrate, and forming an N-type heavily doped layer on the surface of the P-type semiconductor substrate.

[0056] Such as figure 2 As shown, a conventional P-type Si substrate 101 can be used, and an N-type heavily doped layer 102 is formed on the surface of the P-type Si substrate 101 by ion implantation. In this embodiment, the injection element may be As.

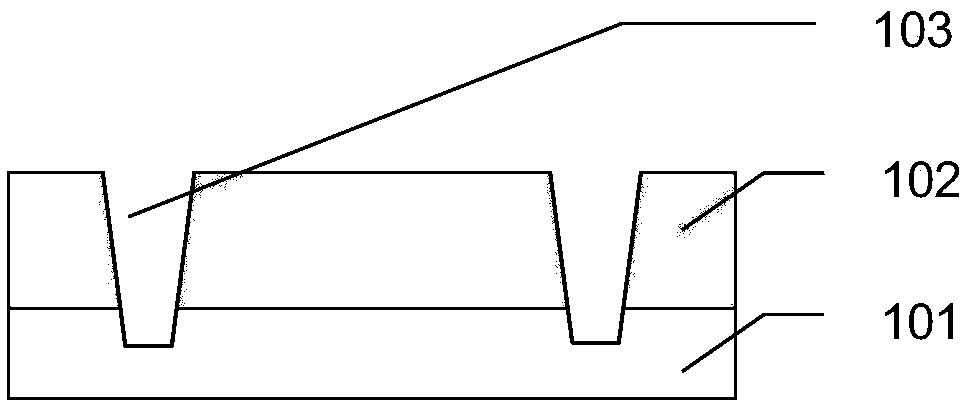

[0057] Step S02: forming shallow trench isolation on the P-type semiconductor substrate.

[0058] Such as image 3 As shown, a groove 103 is formed on the ...

Embodiment 3

[0068] Please refer to Figure 8 , Figure 8 It is a schematic structural diagram of a high-density phase-change memory according to the second preferred embodiment of the present invention. Such as Figure 8 As shown, a high-density phase-change memory of the present invention includes: Schottky diodes 205 and 208 , a phase-change layer 211 and an upper electrode 212 from bottom to top. The Schottky diode includes a semiconductor layer 205 and a metal layer 208 capable of forming a Schottky barrier with the semiconductor layer. The metal layer 208 also serves as the bottom electrode of the phase change layer.

[0069] Different from Embodiment 1, in this embodiment, the high-density phase-change memory can be arranged on a semiconductor substrate 201; the semiconductor layer 205, the phase-change layer 211 and the upper electrode 212 are planar structures arranged from bottom to top, The metal layer 208 is connected with a planar bottom surface and vertical sidewalls, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com