Defoaming formulations containing organopolysiloxanes

A technology of polysiloxane and defoamer, which is applied in the direction of defoamer, anti-foam pulping process, detergent compounding agent, etc., and can solve problems such as difficult to handle products, uncertainty, poor reproducibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0258] Production of organosilicon compound (A):

[0259] a) Silicone compound A1 :

[0260] In a 500ml three-necked flask, the balance (equilibrate) of dimethylsiloxy and vinyldimethylsiloxy units with an iodine value of 101.0g of 22.0 and 2.7g of trimethylsiloxy units ( Trimethylsiloxy unit) end-blocking and hydrolyzate of hydromethyldichlorosilane with a chain length of about 55 Si units, 120.0g OH-end-blocking polydimethylsiloxane (viscosity of 62mm 2 / s) (25.0°C; capillary number II) and the balance of 28.6g dimethylsiloxy and trimethylsiloxane units (viscosity of 35mm2 / s) (25.0°C; capillary number II) with 250ppm of PNCl 2Equilibrate for two hours at 120° C. and a reduced pressure of 20 mbar. by adding NaHCO 3 deactivate the catalyst. After filtration and removal of volatile components at 160 °C and a reduced pressure of 40 mbar, the polysiloxane is obtained A1 , its viscosity is 81mm 2 / s (25.0°C; capillary number II), the iodine value is 13.3, and the H content...

Embodiment 2

[0268] Production of organopolysiloxane (1):

[0269] a)Organopolysiloxane (1-1) :

[0270] In a 250 ml three-necked flask, 100.0 g of polysiloxane was dissolved in 50 ml of xylene together with 0.2 g of Karstedt Pt catalyst in toluene solution (Pt content: 0.3% by weight) A1 Heat to 90°C for 3.5 hours. During the final cooling, 0.3 g of diallyl maleate was added. The xylenes were removed at 90° C. and a reduced pressure of 32 mbar. A polysiloxane with a viscosity of 425 mPas (measured at 25°C and a shear rate of 11 / s) was obtained (1-1) .

[0271] organopolysiloxane (1-1) The production therefore uses only polysiloxane A1 , so the main component is the structural unit (IV), where x=52. (1-1) Is in the form of a flowable compound that does not tend to gel. Therefore it is not necessary to use inert solvents.

[0272] b)Organopolysiloxane (1-2) :

[0273] In a 250ml three-necked flask, 100.0g polysiloxane A2 With 55.0 g of linear vinyldimethylsilyl-terminated pol...

Embodiment 3

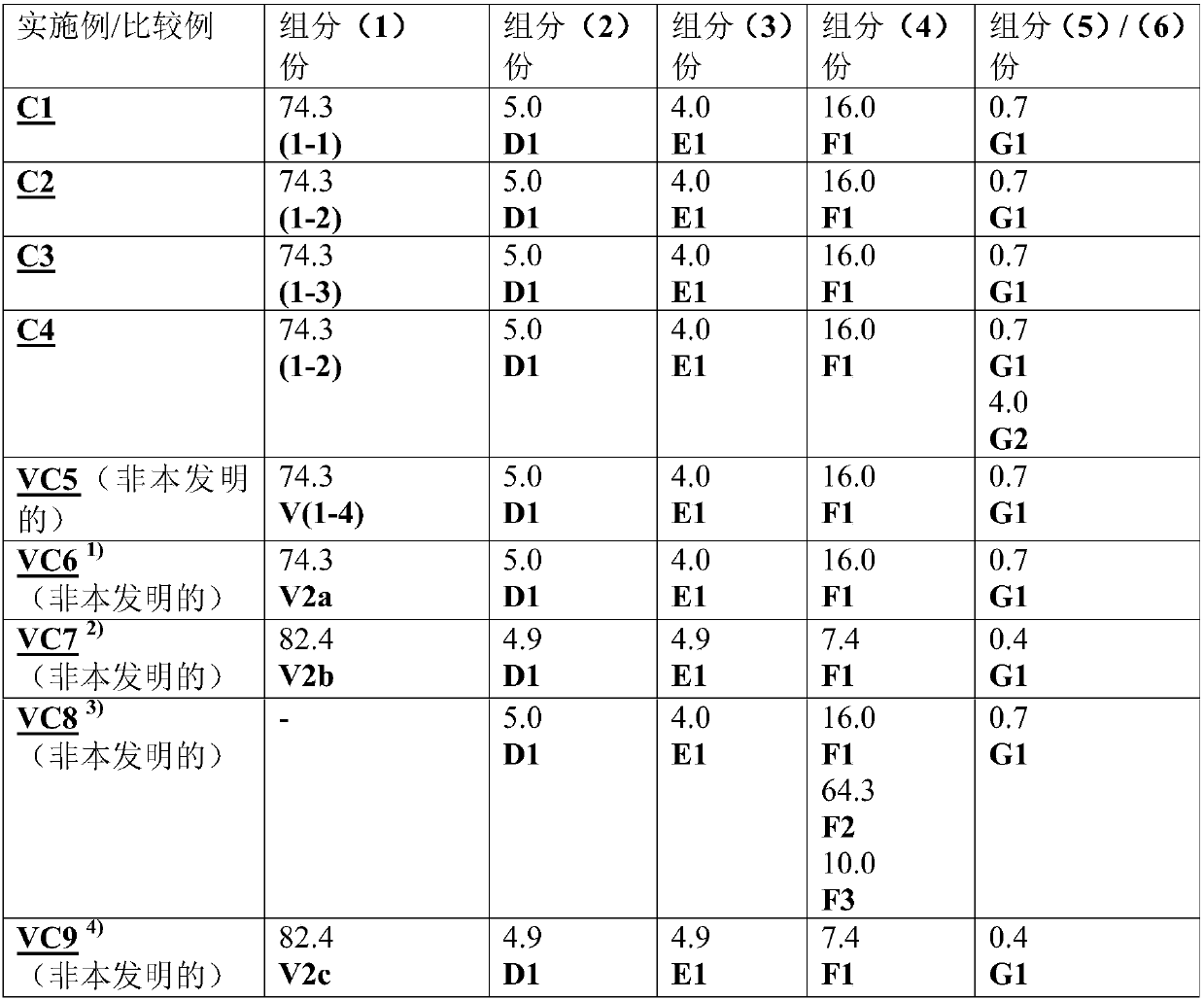

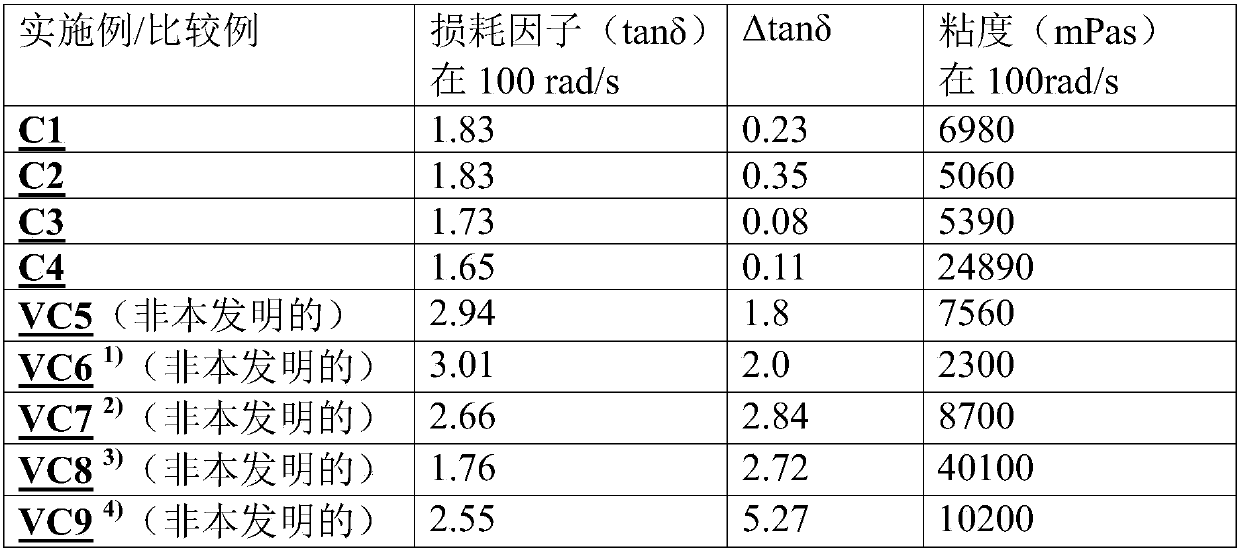

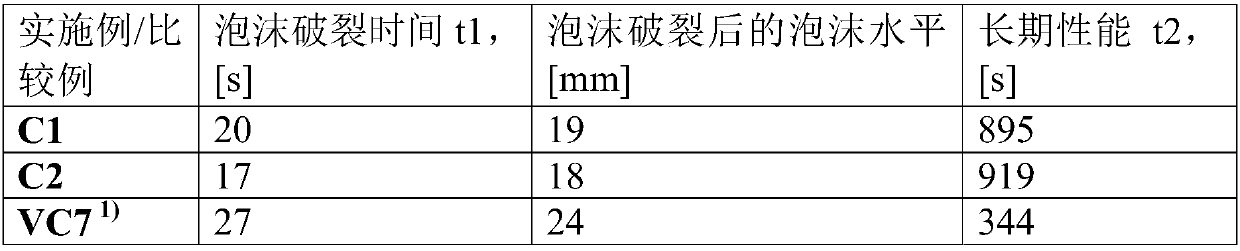

[0295] Production of antifoam formulations C1-C4 according to the invention comprising organopolysiloxanes (1) and production of antifoams not according to the invention Dosage formulations VC5-VC9:

[0296] To produce antifoam formulations, the substances described in Table 1 were mixed with a dissolver and heated to 150°C in the presence of 1500ppm KOH (20% methanol solution) for 4 hours, and after cooling, the dissolved Homogenize again.

[0297] Table 1 Composition of the defoamer formulation

[0298]

[0299] 1) Comparative Test VC6 according to EP 516 109 A1

[0300] 2) Comparative Test VC7 according to EP 434 060 B2

[0301] 3) Comparative test VC8 according to WO 2011 / 069868 A2

[0302] 4) Comparative test VC9 according to EP 217 501 A2

[0303] Substances used:

[0304] D1: BET surface area is 300m 2 / g of hydrophilic pyrogenic silica (available from Wacker Chemie AG, Germany under the trade name T30 obtained)

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com