Device and system for rotary indirect thermal desorption

A thermal desorption and rotary technology, applied in the field of soil remediation, can solve the problems of high heating temperature, large processing capacity, low liquid content, etc., achieve rapid diffusion and release, realize recycling, ensure stability and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

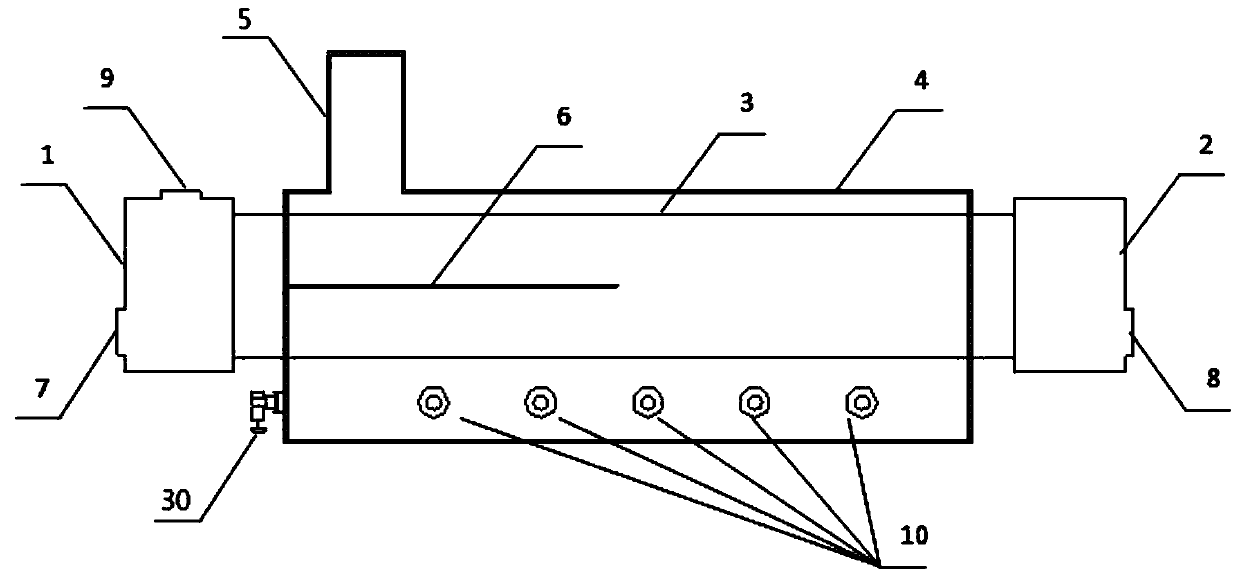

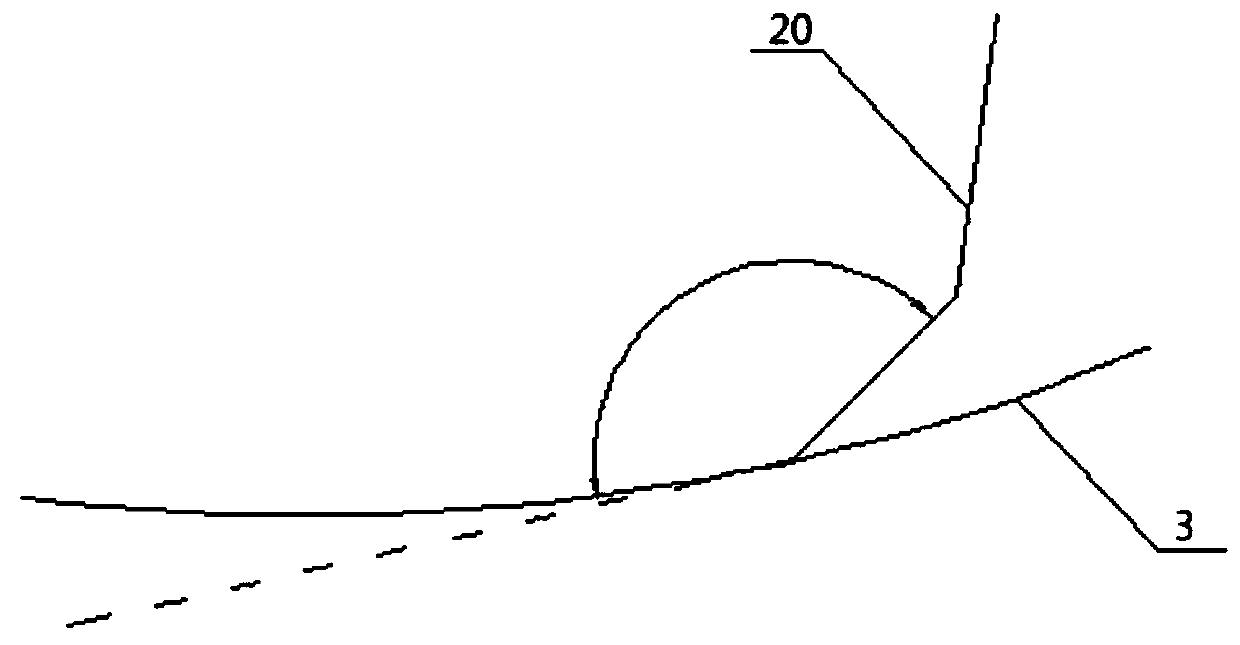

[0024] Such as figure 1 As shown, a rotary thermal desorption device includes a kiln head 1, a kiln tail 2, a rotary cylinder 3 and a fixed combustion chamber 4, and the kiln head 1 is provided with a feed port 7 and an exhaust port 9, so The kiln tail 2 is provided with a discharge port 8, the bottom of the combustion chamber 4 is provided with a plurality of burners 10, and the chimney 5 is arranged on the top of the front end of the combustion chamber 4. At the initial stage of device startup, the bottom of the combustion chamber 4 is evenly discharged horizontally. The multiple burners 10 of the cloth provide high-temperature flue gas and heat, and the organic polluted soil enters the kiln head 1 and the rotary cylinder 3 through the feed port 7, and the straight line formed by the kiln head 1, the rotary cylinder 3 and the kiln tail 2 There is an included angle with the horizontal plane, the angle is 1-3°, and the feed port 7 is higher than the discharge port 8, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com