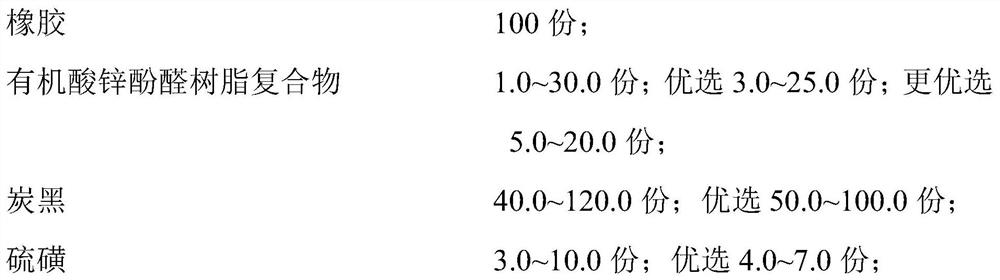

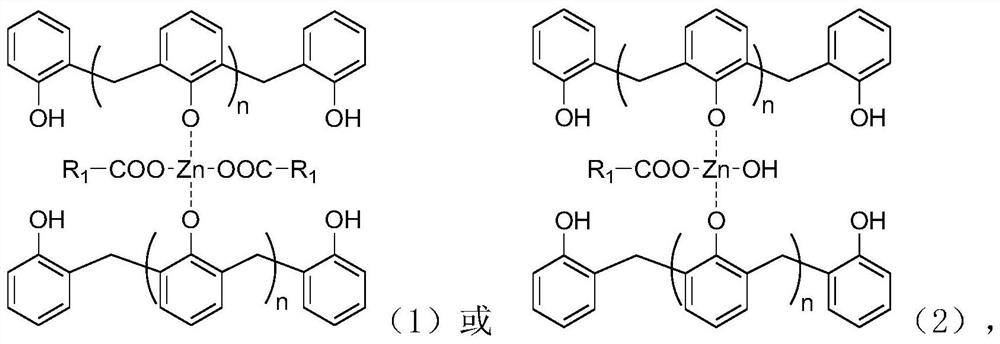

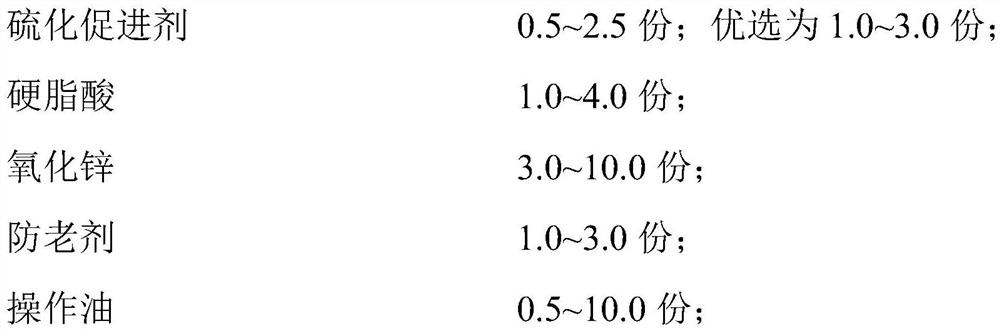

A kind of rubber composition containing organic acid zinc phenolic resin compound and its preparation method and application

A technology for a rubber composition and a phenolic resin, which is applied in the field of rubber materials, can solve the problems of failing to exhibit performance, insufficient cross-linking degree of a compound of an alkyl phenolic resin and an organic acid zinc salt, etc., and achieves a good anti-reversion effect. , The effect of improving mechanical properties and improving adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. It should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they are all deemed to be included in the present invention.

[0045] Preparation of composite samples of organic acid zinc and phenolic resin

[0046] The preparation method of zinc organic acid and phenolic resin compound in the embodiment, concrete steps are as follows:

[0047] The preparation of organic acid zinc phenolic resin compound by chemical melt blending method comprises the following steps: adding phenolic resin into a four-neck flask, and installing a reflux device, a stirring paddle, a thermometer and an electric heating device. Under the protection of nitrogen, heat SL2005 phenolic resin (softening point temperature 115.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com