Extraction method of metal ions in lithium ion battery leaching solution by using ionic liquid

A technology of lithium ion battery and ionic liquid, which is applied in the field of extraction and separation of metal ions in leachate of waste nickel cobalt lithium manganate battery cathode sheet, can solve the problems of volatility, toxicity, flammability of extractant, etc., and achieve high extraction capacity and stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

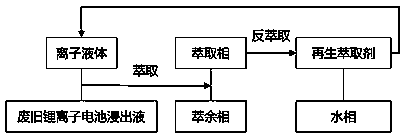

Method used

Image

Examples

Embodiment example 1

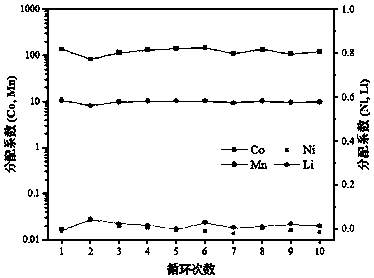

[0017] Implementation case 1: ionic liquid extraction-stripping cycle.

[0018] The specific content is as follows:

[0019] step one:

[0020] Extraction process: add a certain volume of water to the ionic liquid to dilute and reduce the viscosity, take 5mL of the extractant and mix the same volume with the metal ion leachate of the lithium battery positive plate, and shake and mix for 15 minutes at 60 degrees Celsius. In the metal ion leaching solution of the positive plate of the lithium battery, the concentration of each metal ion is 4502 ppm for nickel ions, 1782 ppm for cobalt ions, 2846 ppm for manganese ions, and 734 ppm for lithium ions.

[0021] Step two:

[0022] Separation process: Centrifuge at 5000 rpm for 2 minutes, separate the extract phase and the raffinate phase, and separate the two phases.

[0023] Step three:

[0024] Back-extraction process: add a certain volume of water to the extraction phase and mix, shake and mix for 15 minutes at 60 degrees Cels...

Embodiment example 2

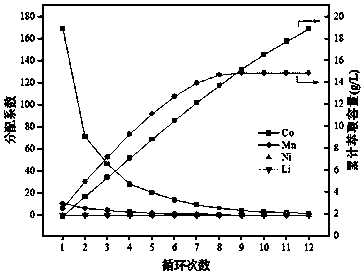

[0027] Implementation Case 2: Ionic Liquid Continuous Extraction Cycle.

[0028] The specific content is as follows:

[0029] step one:

[0030] Extraction process: add a certain volume of water to the ionic liquid to dilute and reduce the viscosity, take 5mL of the extractant and mix the same volume with the metal ion leachate of the lithium battery positive plate, and shake and mix for 15 minutes at 60 degrees Celsius. In the metal ion leaching solution of the positive plate of the lithium battery, the concentration of each metal ion is 4502 ppm for nickel ions, 1782 ppm for cobalt ions, 2846 ppm for manganese ions, and 734 ppm for lithium ions.

[0031] Step two:

[0032] Separation process: Centrifuge at 5000 rpm for 2 minutes, separate the extract phase and the raffinate phase, and separate the two phases.

[0033] Step three:

[0034] Circular extraction process: Take 5mL of the extractant in step 2 and mix it with the metal ion leaching solution of the positive plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com