High-temperature insecticidal weeding ploughing machine

A soil plow machine and high-temperature technology, applied to devices for capturing or killing insects, plows, equipment for eliminating weeds, etc., can solve problems such as non-cooperation, non-coordination, and restrictions on agricultural production upgrading and reform, and achieve wisdom the effect of agriculture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

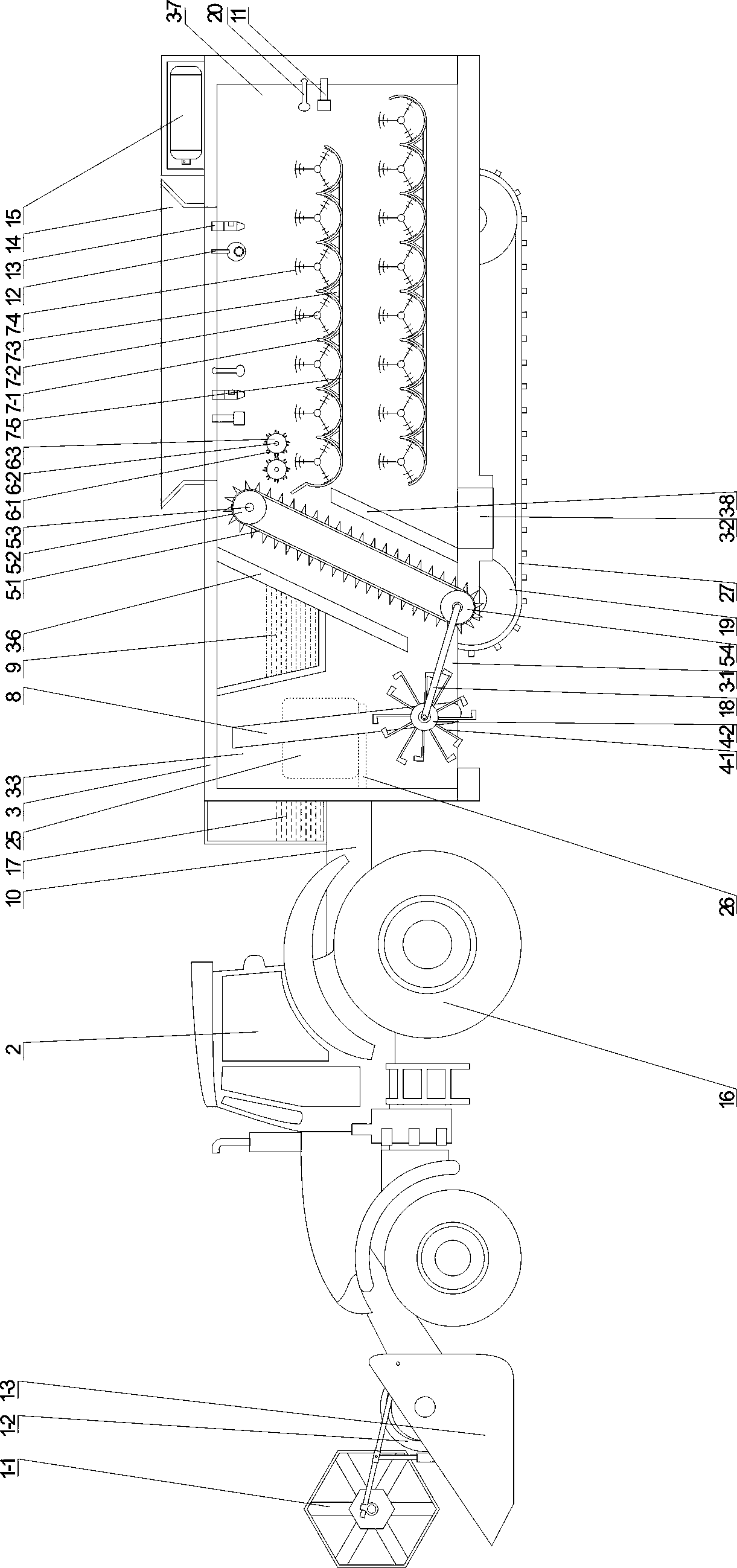

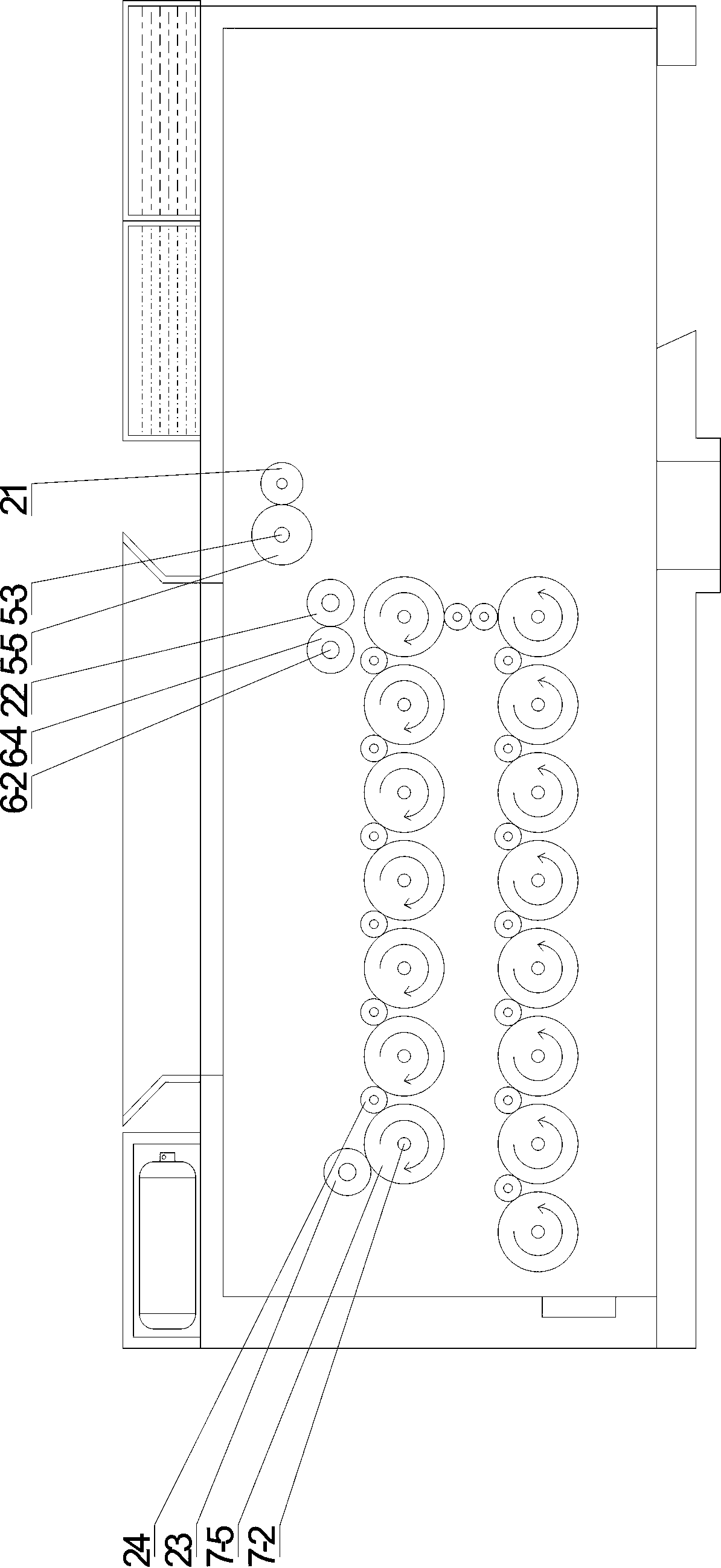

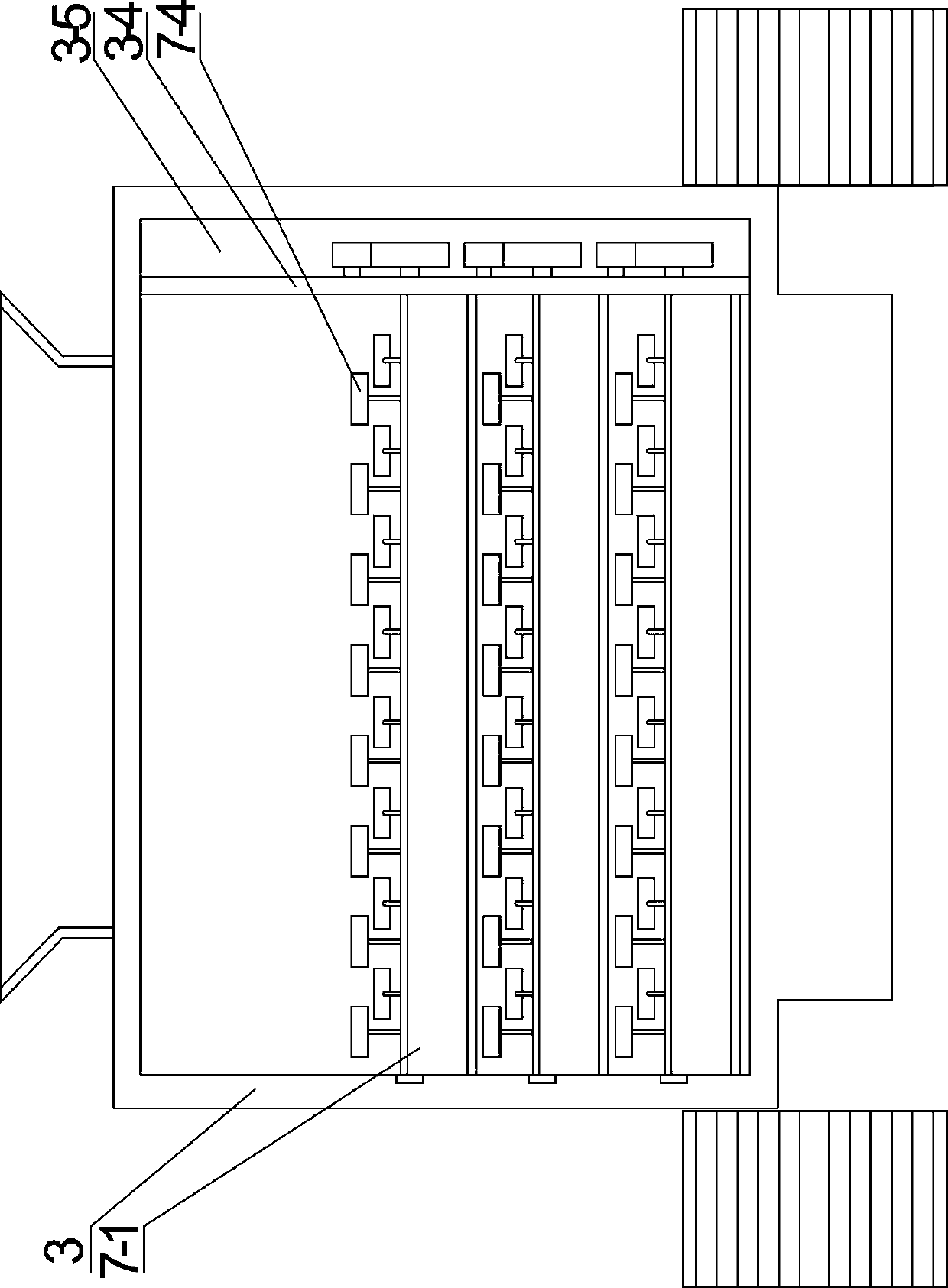

[0030] Embodiment 1, a high-temperature insecticide and weeding plow machine, including a driving headstock 2, crawler wheels 19, crawler belts 27, driving wheels 16, and a carriage 3, a grass-breaking structure 1 is installed in front of the headstock, and the headstock is connected to the carriage through a trailer 10, the carriage The proximal part along the length direction is provided with a dividing plate 3-4 to separate the carriage into a processing area and a transmission area 3-5, and the near middle part in the processing area is provided with an upper heat shield 3-6 and a lower heat shield 3- 8. The upper and lower heat insulation boards are parallel to each other, forming a transportation channel between them, and separating the processing area into the rotary soil area 3-3 and the stir-frying area 3-7. There is a long rectangular soil at the bottom of the car box rotary soil area Entrance 3-1, soil outlet 3-2 is provided at the front bottom of the stir-frying are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com