Fine grain magnesium alloy pipe plastic processing method

A magnesium alloy tube and plastic processing technology, applied in the field of magnesium alloy tube manufacturing, can solve the problems of complex process, poor adaptability of process equipment, and high production cost, and achieve the effects of good process flexibility, automatic operation, and short processing flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] This embodiment is a plastic processing method for a ZK60 magnesium alloy pipe with a wall thickness of 1.5 mm and an inner diameter of 100 mm, comprising the following steps:

[0035] Step 1, selecting a bottomed ZK60 magnesium alloy extruded tube blank 31 with a grain size of 6-25 μm, an inner diameter of Φ100 mm, and a wall thickness of 6 mm;

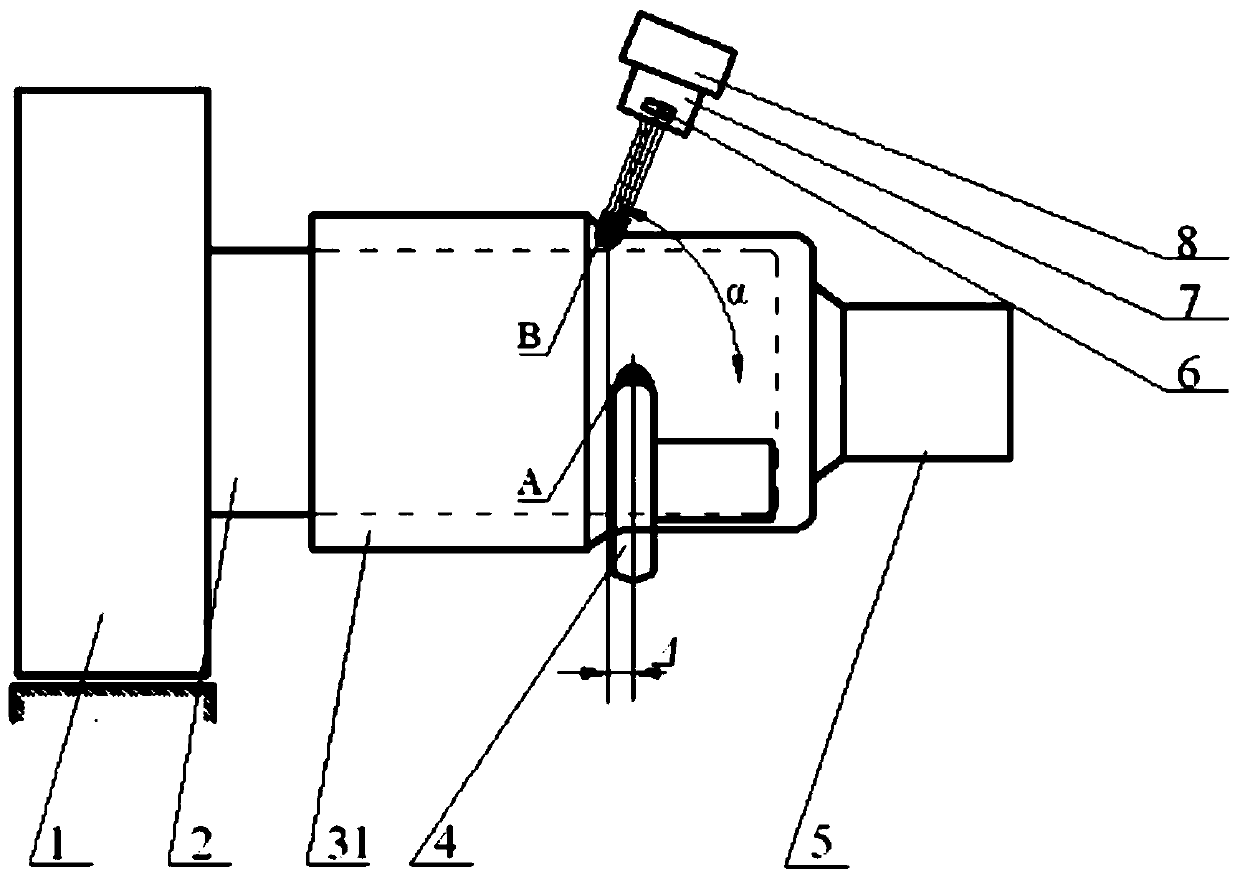

[0036] Step 2, the AZ31 magnesium alloy extruded tube blank 31 is sleeved on the mold 2, and the bottom of the tube wall of the magnesium alloy extruded tube blank 31 is used for positioning, and then fixed on the mold 2 with the fixing device 5, and the mold 2 is fixed on the main shaft 1 on (such as figure 1 shown);

[0037] Step 3, setting the initial processing position of the working head 4, the working head 4 includes two working heads, and the two working heads are symmetrically arranged on both sides of the magnesium alloy extruded tube blank 31 in the circumferential direction, and the laser heating head 7 is adjuste...

example 2

[0047] This embodiment is a plastic processing method for an AZ31 magnesium alloy pipe with a wall thickness of 3 mm and an inner diameter of 100 mm, comprising the following steps:

[0048] Step 1: AZ31 magnesium alloy cast tube billet 32 is selected, with an average grain size of 80 μm, an inner diameter of Φ100 mm, and a wall thickness of 30 mm;

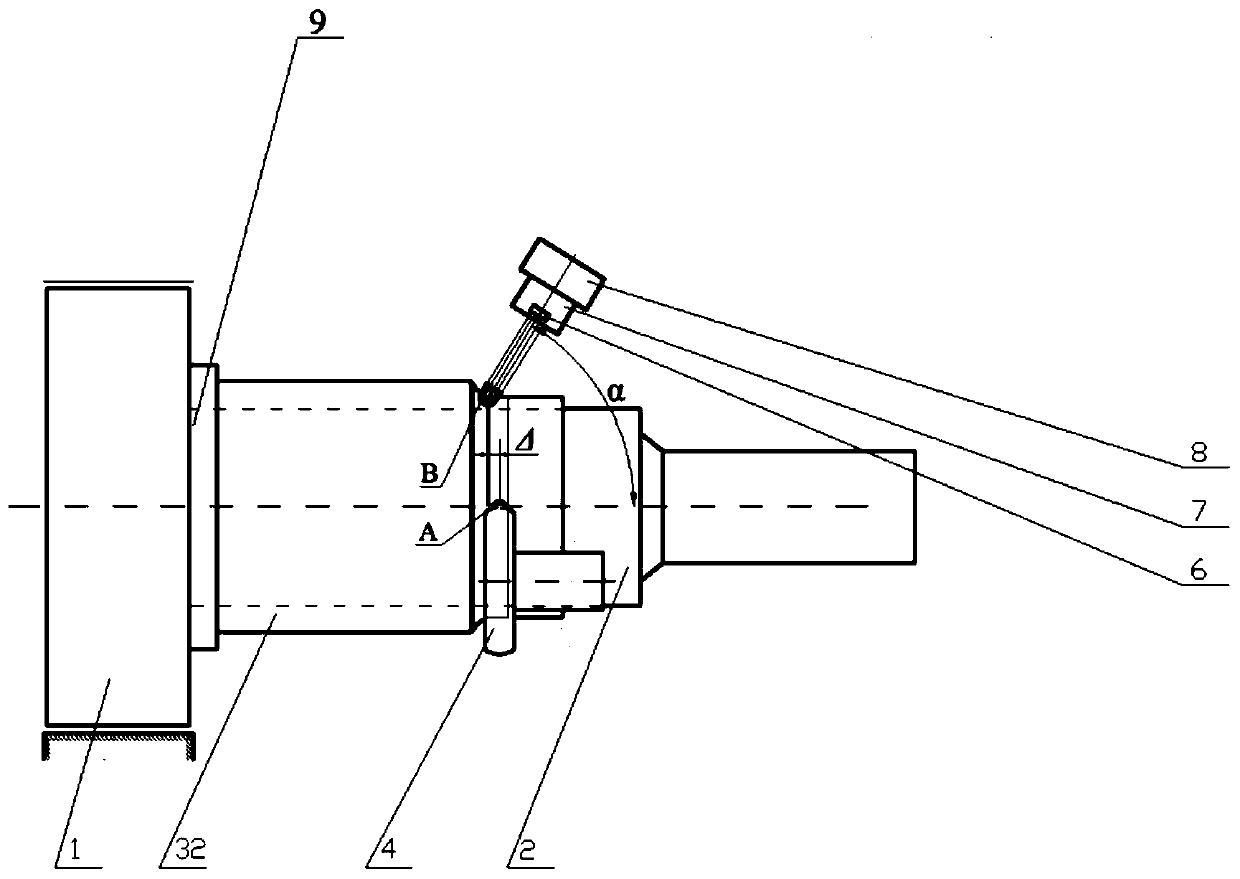

[0049] Step 2, the AZ31 magnesium alloy cast tube blank 32 is sleeved on the mold 2 with an electric heating device inside, and one side of the magnesium alloy cast tube blank 32 is pushed against the chuck 9 for positioning, and the mold 2 is fixed on the spindle 1 (Such as figure 2 shown);

[0050] Step 3, setting the initial processing position of the working head 4, the working head 4 includes three working heads, the three working heads are evenly arranged in the circumferential direction of the magnesium alloy cast tube billet 32 at 120°, and the laser spot B is set The initial irradiation position is to keep the pres...

example 3

[0064] This embodiment is a plastic processing method for an AZ61 magnesium alloy pipe with a wall thickness of 1.5mm and an inner diameter of 100mm, comprising the following steps:

[0065] Step 1: Select the pre-pressed AZ61 magnesium alloy slab, the pre-pressed amount is 6%, the wall thickness of the slab is 3.76mm, the grain size is 10-30μm, and cut it into a magnesium alloy disc with an outer diameter of Φ185mm Blank 33;

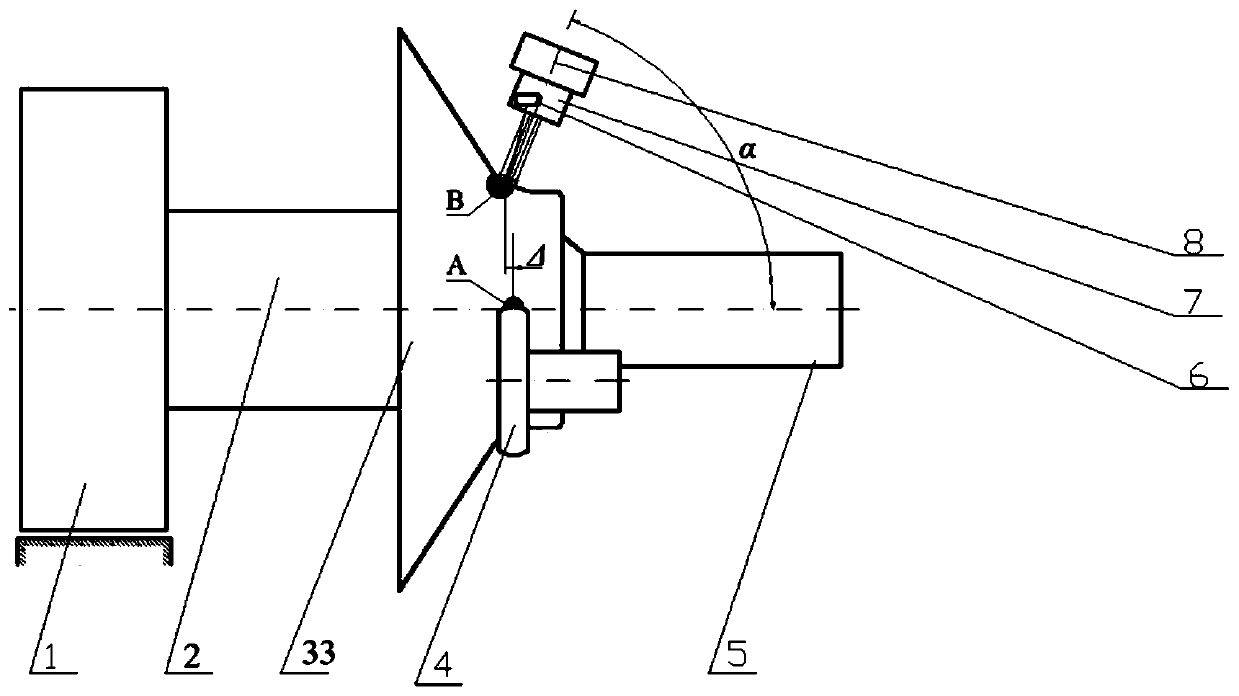

[0066] Step 2, 33 sets of magnesium alloy circular slabs are fixed to the bottom of the mold 2, and then fixed on the mold 2 with the fixture 5, and the mold 2 is fixed on the main shaft 1 (such as image 3 shown);

[0067] Step 3, setting the initial processing position of the working head 4, the working head 4 includes a working head, adjusting the laser heating head 7 so that the angle α formed between the output laser beam and the axial direction of the magnesium alloy circular slab 33 is 40°, Set the initial irradiation position of the laser spot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com